These Breakthrough Nanocoatings Make Solar Panels Self-Clean and 15% More Efficient

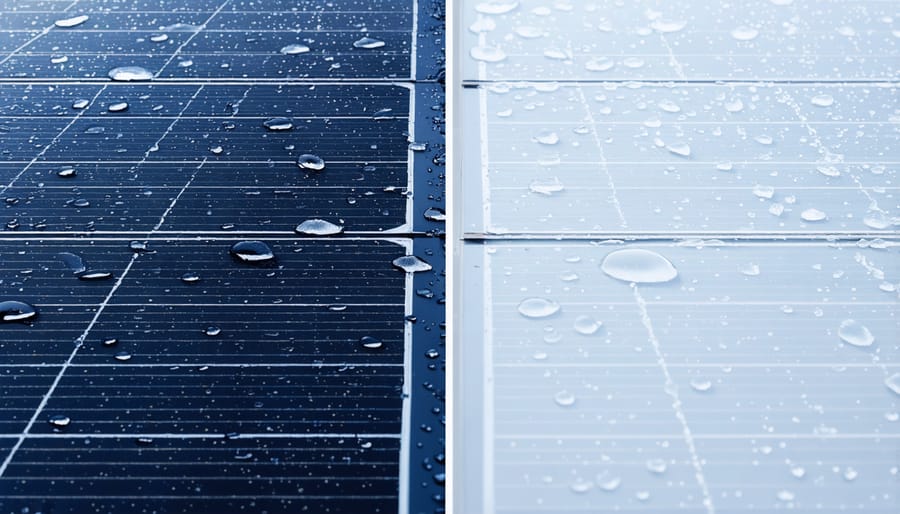

Revolutionary nanocoating technologies are transforming how the core components of solar panels interact with sunlight, delivering up to 30% increased energy yield through advanced surface engineering. These ultra-thin protective layers represent a quantum leap in photovoltaic efficiency, combining anti-reflective properties with self-cleaning capabilities that significantly extend panel lifespan and performance.

European solar installations equipped with the latest hydrophobic and oleophobic coatings demonstrate remarkable resilience against environmental challenges, from acid rain to desert dust. By manipulating materials at the nanoscale, manufacturers have created surfaces that actively repel water, dirt, and organic matter while maximizing light absorption across the solar spectrum.

As sustainability drives innovation across the continent, these sophisticated coating solutions offer a compelling upgrade path for both new installations and existing arrays. The technology not only enhances immediate power output but also reduces maintenance requirements and degradation rates, delivering measurable returns on investment through improved system economics and extended operational lifespans.

How Advanced Nanocoatings Transform Solar Panel Performance

Anti-Reflective Nanocoatings

Anti-reflective nanocoatings represent one of the most significant innovations in modern solar panel construction, dramatically improving light absorption capabilities. These ultra-thin layers, typically measuring just a few nanometers, work by minimising light reflection on the panel’s surface, allowing more sunlight to reach the photovoltaic cells beneath.

The coating’s structure consists of precisely engineered nano-scale patterns that create a gradual transition in refractive index between air and the solar cell surface. This smooth transition effectively eliminates the abrupt interface that typically causes light reflection, enabling panels to capture up to 99% of incoming light across a broad spectrum of wavelengths.

European manufacturers have pioneered multi-layer nanocoating systems that maintain peak performance even in challenging weather conditions. These advanced coatings not only maximise energy absorption during peak sunlight hours but also improve efficiency during overcast conditions, making them particularly valuable in Northern European climates.

Recent developments in self-cleaning nanocoatings have further enhanced their utility, combining anti-reflective properties with the ability to repel dust and organic matter, thereby maintaining optimal performance with minimal maintenance requirements.

Self-Cleaning Properties

Modern solar panel coatings incorporate two remarkable self-cleaning properties that significantly reduce maintenance requirements and enhance overall system efficiency. The first is hydrophobic functionality, which creates a water-repelling surface where water droplets form perfect beads and roll off easily, taking dust and debris with them. This natural cleaning mechanism is particularly beneficial in European regions with frequent rainfall.

The second key feature is photocatalytic activity, where the coating uses sunlight to break down organic matter and pollutants on the panel’s surface. When exposed to UV rays, these advanced coatings trigger chemical reactions that decompose dirt, bird droppings, and other organic materials, preventing them from becoming firmly attached to the panel.

Together, these properties create a synergistic self-cleaning effect that maintains optimal light transmission to the solar cells. During precipitation, the hydrophobic effect ensures water sheets off quickly, while the photocatalytic properties continue working throughout sunny periods, keeping panels cleaner for longer. This dual-action approach significantly reduces the frequency of manual cleaning interventions, leading to lower maintenance costs and more consistent energy production throughout the year.

Latest Innovations in Solar Panel Nanocoating Technology

Smart Temperature-Regulating Coatings

Smart temperature-regulating coatings represent a significant breakthrough in solar panel efficiency management. These innovative solutions address one of the most pressing challenges in photovoltaic technology: temperature-induced performance losses. As solar panels heat up, their efficiency typically decreases by 0.3-0.5% for every degree Celsius above optimal operating temperatures.

These advanced coatings work through a dual mechanism of heat reflection and dissipation. During peak sunshine hours, they reflect excess infrared radiation while allowing visible light to pass through to the photovoltaic cells. Simultaneously, they enhance the panel’s natural heat dissipation capabilities through improved thermal emissivity.

European research institutes have developed temperature-regulating coatings that can maintain panel temperatures up to 20°C cooler than uncoated panels during summer months. This thermal management translates to a 5-8% increase in energy yield, particularly beneficial in Southern European regions where high temperatures can significantly impact solar performance.

The latest generation of these coatings incorporates phase-change materials that actively respond to temperature fluctuations. When panels begin to overheat, these materials absorb excess thermal energy, storing it until temperatures drop. This stored energy is then released during cooler periods, helping to prevent thermal stress and extending the panel’s operational lifespan.

For European installations, these coatings prove especially valuable during heat waves, where traditional panels might suffer significant efficiency losses. The technology’s effectiveness has been demonstrated across various climatic zones, from Mediterranean coastal areas to Alpine regions.

Durability-Enhancing Layers

Modern solar panels require robust protection against diverse environmental challenges, from harsh weather conditions to physical impacts. The latest revolutionary solar materials used in protective coatings significantly enhance panel durability while maintaining optimal performance.

These specialized durability-enhancing layers typically consist of multiple protective elements. The outermost layer features advanced hydrophobic properties, allowing rainwater to easily slide off while carrying dust and debris with it. This self-cleaning mechanism helps maintain panel efficiency while reducing maintenance requirements.

Beneath this, anti-reflective layers work in conjunction with UV-resistant compounds to shield the solar cells from harmful radiation. These protective elements prevent degradation of the panel’s internal components while ensuring maximum light absorption for energy generation.

Impact-resistant layers provide crucial protection against hail, falling branches, and other physical threats common across European climates. Modern coating technologies incorporate nano-scale materials that distribute impact forces evenly across the panel surface, significantly reducing the risk of cracking or structural damage.

Temperature-regulating elements within these protective layers help maintain optimal operating conditions. By managing heat distribution and preventing thermal stress, these coatings extend panel lifespan and maintain consistent energy production levels, even during extreme weather events.

These durability enhancements typically guarantee panel protection for 25-30 years, making them a crucial investment for long-term solar energy solutions.

Real-World Performance Benefits

Efficiency Gains

Recent studies across European solar installations demonstrate significant performance improvements through advanced coating technologies. Field tests conducted in 2023 show that high-quality anti-reflective coatings can increase energy yield by 3-5% annually, while self-cleaning hydrophobic coatings maintain this efficiency gain by reducing soiling losses by up to 40%.

In Mediterranean regions, where dust and pollution are prevalent, coated panels have shown remarkable resilience. Data from Spanish solar farms indicates that coated panels maintain 98% of their initial efficiency after one year, compared to 93% for uncoated panels. This translates to approximately €2,000 additional revenue per megawatt annually.

Northern European installations benefit particularly from anti-reflective coatings during low-light conditions. Swedish research demonstrates up to 6% improved performance during morning and evening hours, with an average annual boost of 4.2% in total energy generation.

The latest nano-coating technologies have achieved even more impressive results. Laboratory tests at leading European research institutes show potential efficiency gains of up to 8% when combining anti-reflective and anti-soiling properties. While real-world performance typically settles at 5-7%, this still represents a significant return on investment, with most installations recovering coating costs within 2-3 years through increased energy production.

Maintenance Cost Reduction

Solar panel coatings significantly reduce maintenance costs through several key mechanisms. By creating a protective barrier against dirt, dust, and environmental pollutants, these coatings minimize the frequency of cleaning interventions. Studies across European installations show that coated panels require cleaning 2-3 times less often than uncoated ones, resulting in substantial labour cost savings.

The self-cleaning properties of advanced hydrophobic coatings enable rainfall to naturally wash away accumulated debris, reducing the need for manual cleaning. This automated maintenance feature is particularly valuable for large-scale installations and roof-mounted systems where access can be challenging and costly.

Financial analysis reveals that coating applications typically pay for themselves within 2-3 years through reduced maintenance expenses alone. A medium-sized commercial installation in Germany documented annual maintenance savings of €2,000-3,000 after coating application, while similar facilities in Spain reported up to 40% reduction in cleaning costs.

Beyond direct maintenance savings, coatings help preserve the panel’s surface integrity, preventing micro-scratches and degradation that could necessitate premature replacement. This extended lifespan protection represents significant long-term cost benefits, with many manufacturers now offering warranties of up to 15 years on coated panels.

Implementation and Installation Considerations

Professional Application Process

The professional application of solar panel coatings requires careful preparation and precise execution to ensure optimal performance. Before beginning the solar panel installation, surfaces must be thoroughly cleaned using specialized solutions to remove any dust, debris, or contaminants that could affect coating adhesion.

The coating process typically involves several key steps. First, technicians conduct a detailed inspection of the panels to identify any damage or irregularities. Next, they apply a primer layer using advanced spray equipment under controlled temperature and humidity conditions. The main coating is then applied in thin, uniform layers, often requiring multiple passes to achieve the desired thickness.

Environmental conditions play a crucial role during application. The ideal temperature range is between 15-25°C, with relative humidity below 75%. Professional installers use climate-controlled environments or schedule installations during appropriate weather conditions to ensure proper curing.

Quality control measures include thickness testing, adhesion checks, and visual inspections throughout the process. The entire application typically takes 24-48 hours, including curing time. Post-installation monitoring ensures the coating performs as expected, with maintenance schedules established based on local environmental conditions and exposure levels.

For optimal results, only certified professionals should perform the coating application, as they possess the necessary equipment, expertise, and understanding of safety protocols required for this specialized process.

Long-term Maintenance Requirements

Maintaining coated solar panels requires significantly less effort compared to uncoated ones, but regular attention ensures optimal performance and longevity. For best results, inspect your coated panels quarterly, paying special attention to any visible changes in the coating’s appearance or performance metrics.

Clean your coated panels using soft water and a non-abrasive cloth or sponge. Avoid harsh cleaning agents or abrasive materials that could damage the protective coating. In most cases, natural rainfall will handle much of the cleaning, thanks to the self-cleaning properties of modern hydrophobic coatings.

Monitor your system’s performance data regularly through your inverter or monitoring system. Any unexpected drops in efficiency might indicate coating wear or damage requiring professional attention. Most quality coatings last 10-15 years, but environmental factors like extreme weather conditions or pollution levels can affect their durability.

Schedule professional inspections annually to assess coating integrity and reapplication needs. These inspections should include:

– Visual examination for coating deterioration

– Performance testing to verify maintained efficiency

– Assessment of edge sealing and junction points

– Documentation of any areas requiring attention

Keep detailed maintenance records, including cleaning dates, performance measurements, and professional inspections. This documentation proves valuable for warranty claims and helps track the coating’s long-term effectiveness. Most European solar installation companies offer maintenance packages specifically designed for coated panels, ensuring proper care throughout their lifetime.

Nanocoating technologies have revolutionized the solar energy landscape, offering European businesses and homeowners unprecedented opportunities to maximize their solar investments. These advanced coatings consistently demonstrate their value through enhanced energy generation, reduced maintenance requirements, and extended panel lifespans. With efficiency improvements ranging from 3% to 8%, and self-cleaning properties that maintain peak performance, nanocoatings represent a significant leap forward in solar technology.

The future outlook for solar panel coatings is particularly promising. Research institutions across Europe continue to develop even more effective solutions, with emerging technologies showing potential for efficiency gains of up to 12%. Additionally, the integration of smart coating materials that adapt to environmental conditions is on the horizon, promising even greater returns on solar investments.

As sustainability remains a key priority for European energy policies, the adoption of nanocoating technologies is expected to accelerate. This growth will likely drive down costs while improving accessibility and performance, making solar energy an increasingly attractive option for both residential and commercial applications. The continued evolution of these innovative solutions will play a crucial role in Europe’s transition to renewable energy, ensuring a cleaner, more sustainable future for generations to come.

Leave a Reply