Solar Panel Components That Power Your Home’s Energy Future

Solar panels transform sunlight into clean electricity through an intricate network of core components of solar panels, each engineered to maximize energy generation and system longevity. Understanding these essential elements empowers homeowners and businesses to make informed decisions about their renewable energy investments and ensure optimal system performance.

From the photovoltaic cells that capture solar energy to the sophisticated inverters that convert DC power into usable AC electricity, every component plays a crucial role in the seamless operation of modern solar installations. These precision-engineered parts work in harmony to deliver reliable, sustainable power while withstanding diverse European weather conditions and maintaining peak efficiency throughout their 25+ year lifespan.

This comprehensive guide examines the vital components that drive solar technology, their specific functions, and how they contribute to the overall performance of your solar energy system. Whether you’re planning a new installation or maintaining existing panels, mastering these fundamentals ensures maximum return on your renewable energy investment.

The Heart of Solar Power: Photovoltaic Cells

Silicon Layers and Electronic Movement

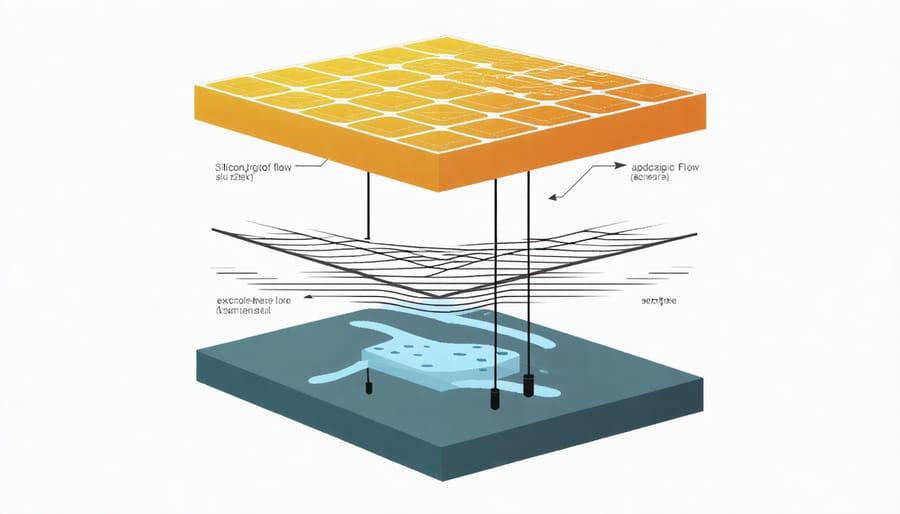

At the heart of every solar panel lies a sophisticated arrangement of silicon layers that forms the foundation of solar energy conversion. These layers consist of two types of silicon: P-type (positive) and N-type (negative), carefully engineered to create what’s known as a P-N junction. This junction is where the magic of solar power generation happens.

When sunlight strikes the silicon layers, it energises the electrons within the material. The N-type silicon layer, which contains extra electrons, and the P-type layer, which has “holes” or spaces for electrons, work together to create an electric field. This field acts like a one-way street for electron movement, preventing them from flowing randomly.

As photons from sunlight hit the silicon layers, they knock electrons loose from their atoms. These freed electrons are then pushed by the electric field towards the conductive metal contacts on the solar cell’s surface. This coordinated movement of electrons creates an electric current that can be captured and utilised.

The efficiency of this process depends on various factors, including the purity of the silicon used and the precision of the manufacturing process. Modern solar cells typically achieve conversion rates between 15% and 22%, though advanced technologies continue to push these boundaries higher.

Cell Types and Efficiency Ratings

Solar panels are available in three primary cell types, each offering distinct advantages for different applications. Monocrystalline cells, crafted from single-crystal silicon, lead the market with efficiency ratings typically ranging from 15% to 22%. Their sleek black appearance and superior performance in direct sunlight make them particularly popular in European residential installations where space efficiency is crucial.

Polycrystalline cells, manufactured from multiple silicon crystals, offer a balanced solution with efficiency ratings between 13% and 17%. While slightly less efficient than monocrystalline cells, their cost-effective production process makes them an attractive option for larger commercial installations. Their distinctive blue, multifaceted appearance comes from the varying crystal orientations within each cell.

Thin-film technology represents the newest innovation in solar cell development, with several variants including amorphous silicon, CIGS (Copper Indium Gallium Selenide), and CdTe (Cadmium Telluride). While their efficiency typically ranges from 10% to 12%, thin-film panels excel in flexibility and performance under diffuse light conditions, making them ideal for building-integrated solutions and regions with variable weather patterns.

The choice between these technologies often depends on specific project requirements, including available space, budget constraints, and local climate conditions. Recent technological advances continue to push efficiency boundaries, with laboratory tests achieving over 26% efficiency in some new-generation cells.

Essential Protection: Solar Panel Glass and Frame

Tempered Glass Technology

The protective glass layer forms the frontline defence of modern solar panels, utilizing advanced tempered glass technology that’s up to four times stronger than conventional glass. This specialized glass undergoes a precise heating and rapid cooling process, creating a surface that can withstand severe weather conditions, including heavy hail and storm debris, while maintaining optimal solar transmission.

Most high-quality solar panels feature low-iron tempered glass, which contains reduced iron content to maximize light transmission. This innovation allows more sunlight to reach the photovoltaic cells beneath, improving overall energy generation efficiency. The glass surface is also treated with sophisticated anti-reflective coatings that significantly reduce light reflection, enabling panels to capture up to 98% of available sunlight.

European manufacturers have pioneered self-cleaning glass technologies, incorporating hydrophobic coatings that allow rain to wash away dust and debris effectively. This feature is particularly valuable in reducing maintenance requirements while maintaining consistent performance. The glass layer also provides essential UV protection, preventing degradation of the underlying solar cells and extending the panel’s operational lifespan.

Modern tempered glass implementations often include micro-texturing patterns that help trap light within the panel, further enhancing energy conversion efficiency while maintaining the structural integrity necessary for long-term outdoor exposure.

Aluminum Frame Construction

The aluminum frame serves as the protective backbone of solar panels, providing crucial structural integrity and mounting capability. Understanding the importance of solar panel frames is essential for ensuring long-term system reliability. These frames are specifically engineered using high-grade aluminum alloys that offer an optimal balance of strength and lightweight properties.

The frame’s primary function is to protect the delicate solar cells and glass components from environmental stresses, including wind loads, snow accumulation, and physical impacts. Its design incorporates special water drainage channels that prevent moisture buildup, while the anodized finish ensures durability against corrosion in various weather conditions common across European climates.

Additionally, the frame provides standardised mounting points that enable secure installation on various surfaces, from residential rooftops to ground-mounted installations. Modern frames feature pre-drilled holes and grooved channels that simplify installation and maintenance procedures while ensuring maximum stability.

The frame’s design also considers thermal expansion and contraction, incorporating flexibility that prevents stress on the glass and internal components during temperature fluctuations. This thoughtful engineering contributes significantly to the typical 25-30 year lifespan of quality solar panels.

Electrical Components: From Panel to Power

Junction Boxes and Bypass Diodes

Junction boxes and bypass diodes play crucial roles in ensuring optimal performance and safety in solar panel systems. Located on the back of each solar panel, the junction box serves as a central connection point where the panel’s internal wiring meets the external cables. This weatherproof enclosure protects these vital connections from moisture, dust, and other environmental factors that could compromise system integrity.

Within the junction box, bypass diodes perform an essential voltage regulation function. These components prevent power loss and potential damage caused by partial shading or panel malfunctions. When a section of the panel is shaded, the bypass diodes create alternative paths for the electrical current, allowing unaffected cells to continue generating power efficiently.

For maximum reliability, junction boxes must be properly sealed and installed in accordance with proper system grounding requirements. Modern junction boxes feature innovative quick-connect systems that simplify installation and maintenance while ensuring secure connections throughout the system’s lifetime. Regular inspection of these components helps maintain optimal energy production and extends the overall lifespan of your solar installation.

Busbars and Connecting Wires

Busbars and connecting wires serve as the vital circulatory system of solar panels, efficiently collecting and transporting the electrical current generated by solar cells. These thin, flat metallic strips, typically made of copper or aluminium, run across the surface of the solar panel in a precise grid pattern. The main busbars, which are thicker and more prominent, collect electricity from thinner connecting wires known as finger electrodes.

The connecting wires form an intricate network that ensures every solar cell contributes to the panel’s overall power output. Modern solar panels often feature multiple busbars (usually 3 to 5) per cell, which helps reduce electrical resistance and improve overall efficiency. This multi-busbar technology has become increasingly popular in European solar installations, as it can increase power output by up to 3% compared to traditional two-busbar designs.

When properly designed and manufactured, these components minimise power losses and ensure reliable performance throughout the panel’s lifetime. Regular visual inspection can help identify any potential issues with busbar connections, though they typically require minimal maintenance due to their robust construction.

EVA and Backsheet Layers

The EVA (Ethylene Vinyl Acetate) and backsheet layers serve as crucial protective elements in modern solar panels, ensuring long-term durability and optimal performance. The EVA layer acts as a sophisticated encapsulant, creating a secure seal around the solar cells and preventing moisture infiltration. This transparent, elastic material also provides excellent optical properties, allowing maximum sunlight transmission while protecting the delicate components beneath.

The backsheet, typically composed of multiple polymer layers, forms the bottom-most protective barrier of the solar panel. This robust layer shields the internal components from environmental factors such as humidity, UV radiation, and temperature fluctuations. In European installations, where weather conditions can vary significantly, these protective layers are particularly vital for maintaining panel efficiency and longevity.

Together, these components create an effective insulation system that not only protects the electrical elements but also ensures optimal operating temperatures. The innovative materials used in modern EVA and backsheet layers contribute significantly to the typical 25-30 year lifespan of quality solar panels, making them a reliable investment for sustainable energy generation.

Maintenance and Component Longevity

Regular Inspection Protocols

Regular inspections are crucial for maintaining optimal solar panel performance and extending system lifespan. For photovoltaic cells, quarterly visual checks should focus on potential microcracks, discoloration, or hot spots that might indicate deteriorating efficiency. The glass surface requires monthly cleaning and inspection for scratches or impact damage, particularly after severe weather events.

Junction boxes should be examined bi-annually for water ingress and secure connections, while ensuring proper ventilation remains unobstructed. The mounting structure demands seasonal checks for corrosion and bolt tightness, especially in regions with high wind exposure. These inspections are typically part of the standard solar panel installation process maintenance schedule.

For inverters, monthly monitoring of operational data and cooling fan functionality is essential. Check display readings for error codes and ensure proper ventilation around the unit. Wiring systems require bi-annual inspection for signs of degradation, loose connections, or wildlife damage, particularly in exposed areas.

The monitoring system should be checked weekly to verify accurate data transmission and battery backup functionality. Document all inspections and maintenance activities in a logbook, noting performance metrics and any observed irregularities. This systematic approach helps identify potential issues early, ensuring sustained energy production and system reliability.

Early Warning Signs of Component Wear

Recognising early warning signs of component wear is crucial for maintaining your solar system’s optimal performance and longevity. Visual inspections can reveal several key indicators that warrant attention. Discolouration or browning of solar cells often signals potential heat damage or delamination issues. Keep an eye out for micro-cracks, which may appear as fine lines across the panel surface and can expand over time if left unaddressed.

For inverter health, unusual sounds or intermittent operation serve as red flags. Monitor your system’s performance data regularly; a steady decline in energy output that doesn’t correlate with seasonal changes might indicate degrading components. Pay attention to error messages on your inverter display, particularly those relating to grid voltage or isolation faults.

Connection points and wiring should be inspected for signs of corrosion, loose fittings, or damaged insulation. In mounting systems, rust spots or loose brackets require immediate attention to prevent safety hazards. Modern monitoring systems can help detect these issues early through performance analytics and automated alerts.

Hot spots on panels, visible through thermal imaging, often indicate cell degradation or electrical issues. If you notice water accumulation under the glass or bubbling in the backing sheet, these could signal seal failures that require professional assessment. Early intervention when these signs appear can prevent more serious damage and maintain system efficiency.

The quality of solar panel components plays a pivotal role in determining the overall performance, reliability, and longevity of your solar energy system. Each element, from the photovoltaic cells to the inverters and mounting structures, contributes to a complex yet harmonious system that transforms sunlight into usable electricity. By investing in high-quality components, European homeowners and businesses can ensure optimal energy production while minimizing maintenance requirements and replacement costs over time.

The synergy between these components is particularly crucial in Europe’s diverse climate conditions, where systems must perform efficiently across varying weather patterns and seasonal changes. Premium components offer superior durability against environmental stresses, better energy conversion rates, and more reliable performance throughout their operational lifetime, typically 25-30 years.

Moreover, quality components contribute significantly to the sustainability goals that drive Europe’s energy transition. Better-performing systems mean more efficient use of renewable resources and a smaller carbon footprint. They also provide better return on investment through increased energy production and reduced maintenance needs.

As solar technology continues to evolve, the importance of selecting the right components becomes even more critical. Whether for residential installations or commercial applications, understanding and choosing quality components ensures that your solar investment delivers maximum value while contributing to a more sustainable energy future.

Leave a Reply