These Revolutionary Battery Recycling Methods Are Reshaping Europe’s Energy Future

The race to revolutionize energy storage has entered a pivotal phase, with breakthrough battery technologies promising to transform how we power our world. From solid-state cells that can charge electric vehicles in minutes to organic flow batteries capable of storing renewable energy at grid scale, next-generation storage solutions are addressing the fundamental limitations of traditional lithium-ion technology. European researchers and manufacturers are leading several groundbreaking innovations, including silicon-based anodes that increase energy density by 40% and advanced recycling processes that recover up to 95% of battery materials.

These developments arrive at a crucial moment as Europe accelerates its transition to renewable energy. With the EU targeting 40% renewable energy by 2030, advanced battery technology represents the missing link between intermittent solar and wind power and reliable, sustainable energy systems. For businesses and homeowners alike, these emerging storage solutions offer unprecedented efficiency, longer lifespans, and significantly reduced environmental impact.

As we stand on the cusp of this energy storage revolution, the integration of artificial intelligence, nanomaterials, and sustainable manufacturing processes is creating batteries that are not just more powerful, but fundamentally smarter and more sustainable than their predecessors.

The Evolution of Battery Recycling Technology

Traditional vs. Modern Recycling Methods

Traditional battery recycling methods primarily relied on pyrometallurgical processes, involving high-temperature smelting to recover basic materials. While effective for lead-acid batteries, these methods proved less efficient for modern lithium-ion batteries, often recovering only 50% of materials while consuming significant energy.

In contrast, modern recycling technologies embrace more sophisticated approaches. Advanced hydrometallurgical processes use water-based solutions to selectively extract valuable materials, achieving recovery rates above 90% for critical elements like lithium, cobalt, and nickel. These methods operate at lower temperatures, reducing energy consumption and environmental impact.

Emerging innovations include direct recycling techniques that preserve the crystal structure of battery materials, allowing for immediate reuse in new batteries. Automated sorting systems powered by artificial intelligence now efficiently separate different battery chemistries, while novel biological processes utilize specialized bacteria to extract metals sustainably.

European facilities are leading this transformation, implementing hybrid recycling systems that combine multiple technologies to maximize material recovery while minimizing environmental impact. These advanced methods not only support circular economy principles but also help secure Europe’s strategic autonomy in battery materials.

European Innovation in Battery Recycling

Europe is leading the charge in sustainable battery recycling, with innovative technologies emerging across the continent. Countries like Sweden, Germany, and France have established advanced facilities that can recover up to 95% of materials from used lithium-ion batteries. The EU’s circular economy initiatives have sparked groundbreaking developments in hydrometallurgical processes, which use water-based solutions to extract valuable metals with minimal environmental impact.

A notable breakthrough comes from Finnish researchers who developed an automated sorting system that can identify and separate different battery chemistries with 98% accuracy. This technology significantly improves recycling efficiency and reduces processing costs. Meanwhile, Belgian scientists have pioneered a low-temperature recycling method that preserves the crystal structure of cathode materials, enabling direct reuse in new batteries.

The European Battery Alliance has fostered collaboration between research institutions and industry partners, resulting in standardized recycling protocols across the continent. These developments not only address environmental concerns but also secure Europe’s position in the sustainable battery supply chain, reducing dependency on raw material imports while creating thousands of green jobs.

Breakthrough Technologies Transforming Battery Recycling

Direct Recycling Technology

Direct recycling represents one of the most promising breakthrough battery innovations in sustainable energy storage. Unlike traditional recycling methods that break down materials into their basic components, direct recycling preserves the crystal structure and composition of cathode materials, maintaining their original functionality and value.

This innovative approach minimises energy consumption and processing costs while reducing the carbon footprint of battery recycling. The process involves carefully separating the cathode and anode materials, removing the electrolyte, and reconditioning the active materials for immediate reuse in new batteries. European research facilities have demonstrated that directly recycled materials can achieve up to 95% of the original battery’s performance.

Several European companies are now implementing direct recycling technologies at industrial scale. The process begins with automated battery sorting and disassembly, followed by physical separation techniques such as density separation and magnetic sorting. The recovered materials undergo minimal processing, often requiring only surface treatment and relithiation to restore their electrochemical properties.

This method is particularly valuable for newer battery chemistries, such as lithium iron phosphate (LFP) and nickel manganese cobalt (NMC) batteries, where preserving the complex material structures offers significant economic and environmental advantages. As battery production continues to grow across Europe, direct recycling is becoming increasingly crucial for creating a sustainable circular economy in the energy storage sector.

Automated Sorting and Processing

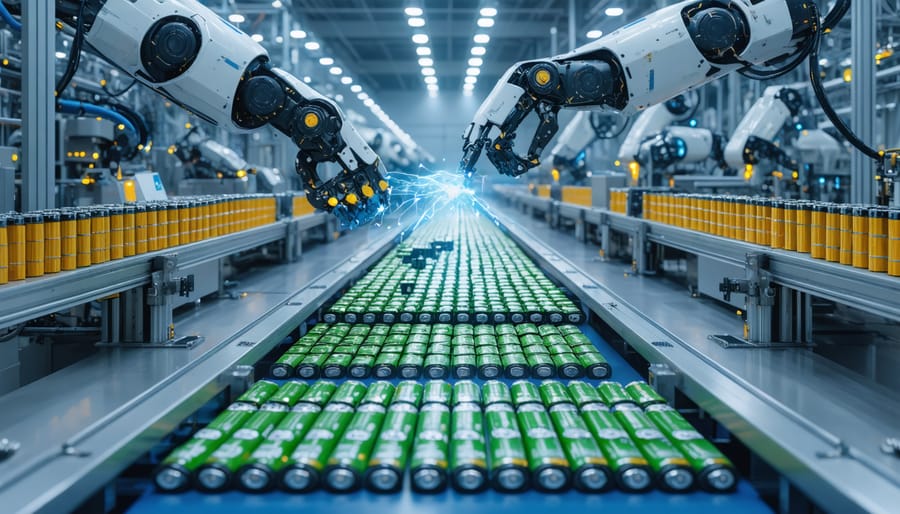

Modern battery recycling facilities are undergoing a remarkable transformation through the integration of artificial intelligence and advanced robotics. These smart systems are revolutionising how we process end-of-life batteries, making recycling more efficient and environmentally conscious than ever before.

At the heart of these facilities, sophisticated sorting systems use machine learning algorithms to identify different battery types and compositions. High-resolution cameras and sensors scan each battery, while AI processes this data in real-time to determine the most appropriate recycling pathway. This AI-powered storage management ensures optimal material recovery and reduces processing errors.

Robotic arms equipped with advanced grippers handle potentially hazardous materials with precision, minimising human exposure to dangerous substances. These systems can work continuously, significantly increasing processing capacity while maintaining consistent quality standards. The automation extends to the separation of valuable materials like lithium, cobalt, and nickel, with smart systems optimising extraction processes based on real-time data analysis.

European recycling facilities are particularly advanced in this domain, with several centres implementing fully automated processing lines that can handle various battery chemistries simultaneously. This technological advancement not only improves recycling efficiency but also supports the EU’s circular economy goals by maximising the recovery of critical raw materials.

Hydrometallurgical Innovations

Recent innovations in hydrometallurgical processes have revolutionised how we recover valuable materials from spent batteries. These advanced chemical techniques employ precise combinations of acids, bases, and selective extraction agents to separate and purify battery components with unprecedented efficiency.

A standout development is the selective leaching process, which enables the recovery of lithium and cobalt with up to 98% purity. This breakthrough has particular significance for European battery manufacturers, who can now access high-grade recycled materials while reducing dependence on raw material imports.

The process begins with mechanical pre-treatment, followed by carefully controlled chemical dissolution stages. Advanced precipitation techniques then allow for the sequential recovery of different metals, while innovative membrane technology helps maintain solution purity throughout the process.

Environmental considerations are central to these new methods. Modern hydrometallurgical systems incorporate closed-loop water recycling and minimal waste generation. Some facilities have achieved up to 90% reduction in water consumption compared to traditional methods, while maintaining high recovery rates.

These technologies are already being implemented across several European recycling facilities, with promising results for both industrial-scale operations and smaller processing plants. The recovered materials meet stringent quality standards for battery manufacturing, effectively closing the loop in battery production and supporting the continent’s transition to sustainable energy storage solutions.

Environmental and Economic Benefits

Resource Conservation and Circular Economy

The transition to next-generation battery technology brings unprecedented opportunities for resource conservation through advanced recycling and circular economy principles. Modern battery recycling facilities across Europe are achieving recovery rates of up to 95% for critical materials like lithium, cobalt, and nickel, significantly reducing the environmental impact of smart energy storage solutions.

Leading manufacturers are implementing design-for-recycling strategies, making batteries easier to dismantle and process at end-of-life. This approach not only conserves valuable resources but also reduces dependency on raw material imports, strengthening Europe’s energy security and industrial autonomy.

The circular economy benefits extend beyond material recovery. Recycled battery components typically require 60-70% less energy to process compared to virgin materials, resulting in substantial carbon emission reductions. Additionally, innovative technologies are enabling the repurposing of aged electric vehicle batteries for stationary storage applications, extending their useful life by 5-10 years before final recycling.

European initiatives are setting global standards for battery sustainability, with new regulations requiring manufacturers to use minimum percentages of recycled content and provide detailed material passports. These measures ensure transparency and traceability throughout the battery lifecycle, supporting the EU’s ambitious climate goals while fostering innovation in sustainable energy storage solutions.

Cost-Effectiveness and Market Impact

The economic impact of next-generation battery technology extends far beyond initial investment costs, offering compelling long-term benefits for both consumers and industries. Current market analyses indicate that production costs for advanced battery systems are decreasing by approximately 15-20% annually, making them increasingly competitive with traditional energy storage solutions.

For European businesses and homeowners, the cost-effectiveness of these new battery technologies becomes apparent through reduced energy bills and enhanced grid independence. Initial calculations suggest that users can expect a return on investment within 5-7 years, compared to 8-10 years for conventional battery systems. This improved payback period is particularly relevant in regions with high electricity costs, such as Germany and Denmark.

The market for next-generation batteries in Europe is projected to reach €35 billion by 2030, driven by increasing demand for renewable energy storage and electric vehicles. This growth is supported by EU initiatives and funding programmes that aim to establish Europe as a global leader in sustainable battery technology.

Manufacturing innovations and economies of scale are expected to further reduce costs by 40-50% over the next five years. This price reduction, combined with improved performance metrics such as longer lifespan and higher energy density, makes these technologies increasingly attractive for wide-scale adoption across residential, commercial, and industrial applications.

Implementation in European Solar Projects

The implementation of next-generation battery technology across European solar projects has marked a significant milestone in the continent’s renewable energy transition. As part of the ongoing European solar storage revolution, several groundbreaking initiatives are demonstrating the practical benefits of advanced energy storage solutions.

In Portugal’s Alentejo region, a 120MW solar farm integrated with state-of-the-art solid-state batteries has achieved remarkable results, maintaining stable power output during peak demand periods while reducing grid connection costs by 30%. The project serves as a blueprint for large-scale solar installations across Southern Europe, showcasing how innovative storage solutions can enhance grid reliability and economic viability.

Germany’s Smart Solar District project in Hamburg demonstrates the potential of community-scale implementation. The initiative combines rooftop solar installations with advanced flow batteries, serving 400 households and achieving 85% energy self-sufficiency. The system’s intelligent management platform optimizes energy distribution based on consumption patterns and weather forecasts, resulting in a 40% reduction in energy costs for residents.

In Denmark, the Aarhus Solar Hub exemplifies industrial application, where next-generation batteries support a 50MW solar array powering manufacturing facilities. The installation uses advanced lithium-sulfur technology, offering 30% higher energy density than traditional lithium-ion solutions while maintaining stable performance in varying weather conditions.

These implementations highlight key advantages of new battery technologies:

– Enhanced grid stability and reduced connection costs

– Improved energy density and storage efficiency

– Better performance in extreme weather conditions

– Increased system lifespan and reduced maintenance requirements

– Lower environmental impact through sustainable materials

The success of these projects has prompted several European nations to accelerate their adoption of advanced storage solutions, with plans to scale up implementation across residential, commercial, and industrial applications.

As we look towards a more sustainable future, the advancement of next-generation battery recycling technologies stands as a crucial cornerstone in Europe’s clean energy transition. The innovative approaches being developed today not only address the growing challenge of battery waste but also create a circular economy that benefits both the environment and industry stakeholders.

The emergence of automated sorting systems, hydrometallurgical processes, and direct recycling methods has transformed what was once considered waste into valuable resources. These technologies are particularly significant for European nations committed to achieving their ambitious climate goals while maintaining technological leadership in sustainable energy solutions.

Looking ahead, the battery recycling landscape shows tremendous promise. Industry experts predict that by 2030, advanced recycling technologies could recover up to 95% of critical materials from used batteries, significantly reducing the need for primary resource extraction. This progress will be essential as the demand for energy storage solutions continues to grow across residential, commercial, and industrial sectors.

For European homeowners and businesses investing in energy storage systems, these developments ensure that their commitment to sustainable energy extends beyond the operational life of their batteries. The continuous innovation in recycling technologies, coupled with supportive EU policies and regulations, creates a robust framework for sustainable battery management that will benefit generations to come.

Leave a Reply