These New Solar Panel Materials Make Recycling Simple and Profitable

Revolutionary advancements in solar panel technology are reshaping how we harness and recycle solar energy, directly addressing growing waste management challenges while maximizing energy generation efficiency. European manufacturers have pioneered breakthrough designs incorporating biodegradable semiconductors and detachable components, enabling up to 95% material recovery at end-of-life. These innovations arrive at a crucial moment as the EU’s renewable energy targets drive unprecedented solar adoption across the continent.

Leading this transformation are next-generation panels featuring perovskite-silicon tandem cells, achieving conversion rates above 29% while using fewer rare earth materials. Their modular design principles represent a fundamental shift from traditional monolithic construction, allowing for component-level repairs and simplified recycling processes.

For industry stakeholders and environmentally conscious consumers alike, these developments signal a new era where solar technology’s environmental impact extends beyond clean energy generation to encompass its entire lifecycle. As European nations accelerate their transition to renewable energy, these innovative panels offer a sustainable solution that aligns with both ecological imperatives and economic objectives.

The Evolution of Solar Panel Design for Recyclability

Traditional Materials vs. New Recyclable Alternatives

Traditional solar panels predominantly use silicon cells encased in glass and aluminium frames, with adhesives that make end-of-life recycling complex and costly. These conventional materials, while durable, present significant environmental challenges when panels reach their end of life after 25-30 years.

However, innovative manufacturers are now introducing recyclable alternatives that maintain high performance while significantly reducing environmental impact. New organic photovoltaic materials and perovskite cells offer promising alternatives to traditional silicon. These materials can be processed at lower temperatures, reducing manufacturing energy consumption by up to 50%.

Recent developments include biodegradable semiconductors and water-soluble adhesives that allow for easy component separation during recycling. Frame materials are shifting from aluminium to recyclable composites, while some manufacturers now use tempered glass that can be easily recovered and repurposed.

These new materials not only simplify the recycling process but also reduce the carbon footprint of panel production. European manufacturers are leading this transition, with several facilities already implementing these sustainable alternatives in their production lines.

European Standards Driving Innovation

The European Union’s commitment to sustainability has become a powerful catalyst for solar panel innovation. Through stringent eco-design regulations and ambitious climate targets, the EU is actively shaping how manufacturers approach material selection and panel design. Recent European recycling innovations have led to breakthrough developments in recyclable components and modular construction techniques.

The EU’s Circular Economy Action Plan has particularly influenced the industry, pushing manufacturers to prioritize easily separable materials and reduce harmful substances in their products. This has resulted in new composite materials that maintain high efficiency while being more environmentally friendly. Notable improvements include lead-free soldering alternatives and frameworks designed for easy disassembly.

These standards have also fostered collaboration between research institutions and manufacturers, creating a robust innovation ecosystem. Companies meeting these requirements gain access to EU markets while contributing to the region’s sustainability goals. The result is a new generation of solar panels that not only generate clean energy but also represent a significant step toward a truly circular economy in the renewable energy sector.

Breakthrough Materials Transforming Solar Panel Recycling

Advanced Polymer Encapsulants

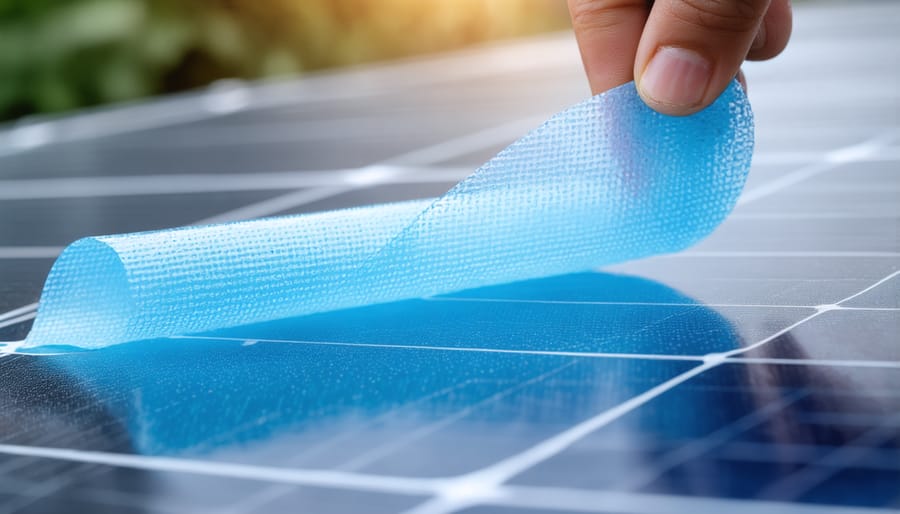

Recent advancements in polymer encapsulant technology have revolutionised how solar panels can be dismantled and recycled at the end of their lifecycle. These innovative polymers serve as protective layers for solar cells while offering a significant advantage: they can be easily separated from other components through thermal or chemical processes.

European researchers have developed thermoplastic polyolefin-based encapsulants that maintain excellent durability and weather resistance while featuring reversible crosslinking properties. This breakthrough allows for straightforward separation of the encapsulant from the solar cells and glass components when it’s time to recycle the panels.

The new generation of encapsulants demonstrates superior UV stability and moisture resistance compared to traditional materials, ensuring a long service life of 25+ years. What makes these polymers particularly noteworthy is their ability to dissolve at specific temperatures without damaging the valuable silicon cells beneath.

Several European manufacturers have already incorporated these recyclable polymers into their production processes, reporting up to 95% material recovery rates during end-of-life processing. This advancement aligns perfectly with the EU’s circular economy goals and helps reduce the environmental impact of solar energy infrastructure.

For installers and end-users, these new encapsulants don’t compromise on performance or durability, yet they significantly enhance the sustainability profile of solar installations. The technology represents a crucial step toward truly sustainable solar energy solutions, addressing both current performance needs and future recycling requirements.

Smart Junction Boxes and Wiring

Modern solar installations are witnessing a revolution in junction box design and wiring systems, making end-of-life dismantling significantly more efficient. The latest smart junction boxes feature snap-fit connectors and modular components that can be easily separated without damaging the surrounding materials. This innovation dramatically reduces the time and effort required for panel decommissioning while ensuring valuable materials can be properly sorted for recycling.

European manufacturers have introduced advanced plug-and-play wiring solutions that eliminate the need for permanent soldering or adhesive connections. These systems utilize high-performance thermoplastic housings that maintain durability throughout the panel’s lifecycle while being fully recyclable. The connections are designed to withstand harsh weather conditions and maintain optimal electrical performance, yet can be disconnected with simple tools when required.

Furthermore, smart junction boxes now incorporate built-in monitoring capabilities that help track panel performance and identify potential issues before they escalate. This technology not only improves maintenance efficiency but also extends panel lifespan through predictive diagnostics. The monitoring systems use detachable sensors and removable circuit boards, ensuring that electronic components can be separately recycled or refurbished.

These innovations align with the European Union’s circular economy objectives, making solar installations more sustainable from production to end-of-life management. The standardisation of these components across different manufacturers is also improving, creating a more unified approach to solar panel recycling across the continent.

Eco-friendly Frame Materials

The evolution of solar panel frame materials represents a significant leap forward in sustainable manufacturing. Modern frames now incorporate recycled aluminum alloys specifically engineered for the solar industry, reducing the carbon footprint of panel production by up to 60% compared to traditional frames. These innovative frames maintain structural integrity while being designed for easy disassembly at end-of-life.

Leading European manufacturers have introduced bio-based composite frames, combining recycled polymers with natural fibres such as hemp and flax. These materials offer excellent durability and weather resistance while being fully recyclable. The composites are lighter than conventional aluminum frames, reducing transportation costs and installation complexity.

A breakthrough development comes in the form of modular frame systems that can be dismantled without special tools. This design philosophy, known as circular manufacturing, ensures that different materials can be separated efficiently for recycling. The frames feature standardised connection points and are free from adhesives that typically complicate the recycling process.

Some manufacturers now offer take-back programmes for their framing systems, creating a closed-loop supply chain. These programmes ensure proper recycling while providing customers with certification of responsible disposal. The initiative aligns with EU sustainability directives and helps businesses meet their environmental compliance requirements.

The latest generation of eco-friendly frames also incorporates smart design features that extend panel lifespan. Enhanced drainage systems prevent water accumulation, while anti-corrosion treatments derived from natural compounds protect the frame without introducing harmful chemicals into the recycling stream.

Economic Benefits of Recyclable Solar Panels

Material Recovery Value

Modern solar panels contain numerous valuable materials that can be recovered and repurposed, making their end-of-life management increasingly important. The most valuable recoverable components include silver, silicon, copper, and aluminium, which together represent significant market value. Studies show that a standard solar panel can yield up to 80% recyclable materials when properly processed.

The economic benefits of recycling these materials are substantial, particularly as raw material prices continue to rise. High-purity silicon recovered from panels can be reprocessed for new solar cells or used in other electronics manufacturing. Silver, despite its small quantity per panel, represents up to 10% of the total material value, making it a crucial recovery target.

European recycling facilities are developing innovative processes to extract these materials more efficiently. Advanced thermal and chemical separation techniques now allow for the recovery of previously difficult-to-separate components, increasing the overall material recovery value. The aluminium frames and junction boxes alone can offset a significant portion of recycling costs.

As the industry matures, the establishment of dedicated recycling infrastructure is creating new opportunities for material recovery, supporting both environmental sustainability and economic viability. This circular approach to solar panel management aligns perfectly with EU sustainability goals while providing tangible financial returns for recycling operators.

Reduced Disposal Costs

The adoption of innovative solar panels with enhanced recyclability significantly reduces disposal costs across the lifecycle of solar installations. Traditional solar panel disposal can cost between €250-400 per tonne, but these new designs cut these expenses by up to 60%. This reduction stems from simplified dismantling processes and the increased value of recoverable materials.

European facility managers and solar farm operators benefit from streamlined end-of-life management, as these panels require less specialized handling during decommissioning. The modular design allows for easier separation of components, reducing labour costs and processing time at recycling facilities. Additionally, the high-purity materials used in these panels maintain their value, offsetting disposal expenses through material recovery.

For businesses and homeowners, this translates to lower lifetime ownership costs and reduced environmental compliance fees. Many European regions now offer incentives for installing easily recyclable solar solutions, further enhancing the financial benefits. The standardised dismantling protocols also mean more recycling facilities can process these panels, creating competitive pricing in the disposal market.

Looking ahead, as recycling infrastructure expands across Europe, disposal costs are expected to decrease further. This trend aligns with circular economy principles and supports the EU’s sustainability targets while providing tangible economic advantages for solar energy adopters.

Implementation and Future Outlook

Integration with Existing Systems

The integration of innovative solar panels with existing infrastructure is remarkably straightforward, thanks to their thoughtful design that maintains compatibility with standard mounting systems and electrical connections. These new-generation panels utilize the same standardised mounting rails and clamps that installers are already familiar with, ensuring a smooth transition from conventional to advanced solar technology.

For residential installations, the panels work seamlessly with existing roof structures, requiring no special adaptations to mounting hardware or support systems. The electrical connections remain compatible with current inverter technology, allowing for easy integration into both new installations and upgrades of existing solar arrays.

Commercial and industrial applications benefit from the panels’ adherence to standard dimensions and connection protocols. This compatibility extends to monitoring systems and smart energy management platforms, enabling businesses to maintain their existing energy management infrastructure while upgrading to more sustainable panel technology.

The panels’ enhanced durability and lighter weight actually simplify installation processes, reducing strain on roof structures and potentially decreasing installation time. Moreover, their improved efficiency means that in many cases, fewer panels are needed to achieve the same energy output, making it easier to work within existing space constraints.

For retrofitting projects, these innovative panels can be integrated gradually, allowing for phased implementation that aligns with budget constraints and maintenance schedules. This flexibility makes the transition to new solar technology both practical and economically viable for European property owners.

Upcoming Innovations

The solar industry is witnessing groundbreaking developments in recyclable materials that promise to revolutionize panel manufacturing. Research laboratories across Europe are developing innovative composite materials that maintain high efficiency while being easier to dismantle and recycle at end-of-life. These advancements align perfectly with next-generation recycling technologies and circular economy principles.

Notable innovations include bio-based encapsulants that replace traditional EVA films, allowing for simpler separation of panel components. These materials demonstrate remarkable durability while being fully biodegradable after controlled processing. Additionally, researchers have developed novel silicon wafer technologies that enable recovery rates above 95% without compromising performance.

European manufacturers are particularly focused on implementing design-for-recycling principles in their upcoming product lines. This includes modular frameworks that allow for easy component replacement and eventual recycling, as well as smart labeling systems that facilitate automated sorting at recycling facilities.

Perhaps most promising is the development of organic photovoltaic materials that can be processed using environmentally friendly solvents. These materials show potential for creating fully recyclable panels while maintaining competitive efficiency rates. Initial pilot projects suggest these innovations could reduce the environmental impact of solar panel production by up to 60% while ensuring sustainable end-of-life management.

The shift towards recyclable materials in solar panel manufacturing marks a crucial turning point in sustainable energy development. By incorporating eco-friendly components and circular design principles, the solar industry is addressing end-of-life concerns while maintaining high performance standards. This commitment to sustainability not only reduces environmental impact but also creates new opportunities for material recovery and waste reduction across Europe. As solar technology continues to evolve, the focus on recyclability ensures that renewable energy solutions truly deliver on their promise of environmental stewardship. For businesses and homeowners alike, investing in recyclable solar panels represents a forward-thinking approach that combines energy independence with responsible resource management, setting a new standard for sustainable energy infrastructure in the European market.

Leave a Reply