These Eco-Friendly Materials Are Revolutionizing Solar Panel Production in Europe

The urgent need for sustainable manufacturing has sparked a revolution in eco-friendly materials, transforming how we produce everything from packaging to building components. Modern innovations in biodegradable polymers, recycled composites, and renewable resources are creating products that perform as well as—or better than—their conventional counterparts while dramatically reducing environmental impact.

European manufacturers are leading this transformation, developing breakthrough materials like mycelium-based packaging, carbon-negative concrete alternatives, and plant-based textiles that decompose naturally. These innovations aren’t just environmentally responsible—they’re economically compelling, with the EU’s eco-friendly materials market projected to reach €125 billion by 2025.

For businesses and consumers alike, the shift toward sustainable materials represents both an environmental imperative and a competitive advantage. From reducing carbon footprints to meeting increasingly stringent regulations, eco-friendly materials offer practical solutions for modern manufacturing challenges. As we advance toward a circular economy, these materials are becoming the new standard in product development, driving innovation across industries while protecting our planet’s finite resources.

This focused approach to sustainable materials doesn’t just address environmental concerns—it’s reshaping entire supply chains and creating new opportunities for businesses committed to responsible production.

The Evolution of Solar Panel Materials

Traditional Materials: Understanding the Environmental Impact

The environmental impact of traditional solar panel materials and manufacturing processes has become a growing concern across European industries. Conventional materials like plastic polymers, synthetic adhesives, and certain metals often rely heavily on fossil fuel-based production methods, contributing significantly to carbon emissions. These materials typically require extensive energy during manufacturing and pose challenges for end-of-life disposal or recycling.

Many traditional materials contain potentially harmful substances that can leach into soil and water systems when improperly disposed of. The production of conventional plastics, for instance, not only depletes finite petroleum resources but also generates substantial greenhouse gas emissions throughout their lifecycle. Similarly, traditional metal extraction and processing methods often involve intensive mining operations that can lead to habitat destruction and water pollution.

The limitations of these conventional materials have sparked innovation in sustainable alternatives, driving the industry towards more environmentally responsible choices that maintain performance while reducing ecological impact.

The Push for Sustainable Alternatives

The drive towards eco-friendly materials in product manufacturing is increasingly shaped by both market demands and regulatory frameworks across Europe. Consumer awareness about environmental impact has reached unprecedented levels, with 73% of European consumers actively seeking sustainable products. This shift in consumer behaviour has prompted industries to innovate and adapt their production methods.

European Union regulations, particularly the European Green Deal and Circular Economy Action Plan, have established stringent guidelines for sustainable manufacturing. These policies encourage companies to adopt eco-friendly materials through incentives and compliance requirements, effectively accelerating the transition towards greener alternatives.

Major retailers and manufacturers are responding by setting ambitious sustainability targets, investing in research and development of bio-based materials, and implementing circular economy principles in their production processes. The financial sector has also played a crucial role, with sustainable investing and green bonds providing capital for eco-friendly innovation.

This combined pressure from consumers, regulators, and investors has created a robust ecosystem that supports the development and adoption of sustainable materials across various industries, from packaging to construction materials.

Breakthrough Eco-Friendly Materials in Modern Solar Panels

Recycled Silicon and Glass Components

The solar industry’s commitment to sustainability extends beyond energy generation to the very materials used in manufacturing. Recycled silicon and glass components play a crucial role in reducing the environmental impact of solar panel production while maintaining high performance standards.

Recycled silicon, sourced from semiconductor manufacturing waste and end-of-life solar panels, can be reprocessed to create new solar cells. This circular approach reduces the energy-intensive process of producing virgin silicon, cutting carbon emissions by up to 30% in the manufacturing phase. European manufacturers have been particularly successful in developing innovative techniques to purify and repurpose silicon waste, achieving quality levels comparable to virgin materials.

Glass components, which typically constitute about 75% of a solar panel’s weight, present significant opportunities for recycling. Advanced processing techniques allow manufacturers to incorporate up to 30% recycled glass in new solar panels without compromising transparency or durability. This practice not only conserves raw materials but also reduces energy consumption during production.

Several European facilities now specialise in solar panel recycling, creating a sustainable supply chain for these materials. The integration of recycled components has become increasingly important as the industry scales up, with manufacturers achieving certification for their recycled content while maintaining strict quality standards. This development represents a significant step toward truly sustainable solar energy solutions, reducing both waste and the demand for virgin materials.

Bio-Based Encapsulation Materials

Bio-based encapsulation materials represent a significant advancement in sustainable product manufacturing, offering environmentally conscious alternatives to traditional synthetic materials. These innovative solutions, derived from renewable resources, are particularly transformative in organic solar technology and other green applications.

Plant-based polymers, including cellulose derivatives and starch-based compounds, are increasingly being utilized as protective barriers in various products. These materials offer excellent biodegradability while maintaining robust protection against environmental factors. Notably, compounds derived from corn starch and sugarcane have shown promising results in providing moisture resistance and structural integrity comparable to conventional synthetic materials.

Recent innovations in bio-based encapsulation include the development of lignin-based formulations, which offer natural UV protection and enhanced durability. These materials are particularly effective in protecting sensitive components while ensuring end-of-life biodegradability. European manufacturers have successfully implemented these solutions in various applications, from electronic components to food packaging.

The adoption of these materials brings multiple benefits: reduced carbon footprint, improved end-of-life disposal options, and decreased reliance on petroleum-based products. Furthermore, many bio-based encapsulants demonstrate superior thermal stability and moisture resistance, making them ideal for demanding industrial applications while maintaining their eco-friendly credentials.

Low-Impact Frame Materials

In the pursuit of sustainable product development, frame materials play a crucial role in reducing environmental impact while maintaining structural integrity. Bamboo has emerged as a leading eco-friendly framing option, offering exceptional strength-to-weight ratios and rapid regeneration cycles of just 3-5 years. This renewable resource requires minimal processing and naturally resists pests, reducing the need for chemical treatments.

Recycled aluminium frames represent another sustainable choice, consuming only 5% of the energy required for primary aluminium production. European manufacturers increasingly utilize recycled aluminium, creating a circular economy while maintaining the material’s durability and lightweight properties.

Engineered wood composites, particularly those certified by the Forest Stewardship Council (FSC), provide robust framing solutions with reduced environmental impact. These materials combine wood fibres with recycled plastics, offering weather resistance and longevity while diverting waste from landfills.

Bio-based composites represent the latest innovation in frame materials. Hemp-based frames, for instance, offer excellent insulation properties and carbon sequestration benefits. Similarly, mycelium-based materials are gaining traction for their biodegradability and minimal production energy requirements.

When selecting frame materials, considerations should include local availability, transportation distance, and end-of-life recyclability. European manufacturers increasingly focus on these factors, offering transparency in their supply chains and environmental impact assessments.

Environmental Benefits and Performance Metrics

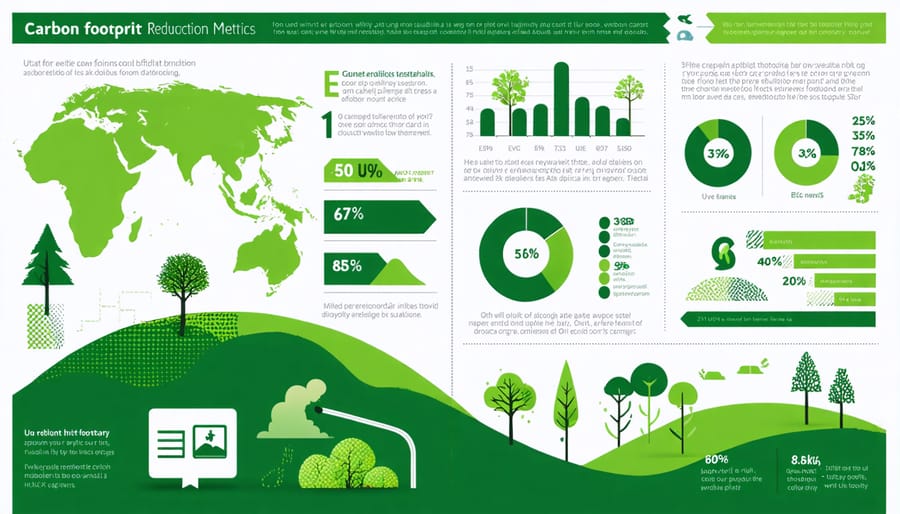

Carbon Footprint Reduction

The adoption of eco-friendly materials in product manufacturing delivers significant environmental benefits, particularly in reducing greenhouse gas emissions. Studies show that sustainable materials can decrease the carbon footprint of solar manufacturing by up to 40% compared to traditional methods. This reduction stems from both the materials themselves and their optimised production processes.

Bio-based polymers, for instance, demonstrate a carbon footprint reduction of 30-70% compared to their petroleum-based counterparts. Recycled aluminium utilisation reduces energy consumption by 95% versus primary production, translating to approximately 9 tonnes of CO2 emissions saved per tonne of material processed.

Advanced bamboo composites, increasingly popular in European construction, sequester carbon throughout their growth cycle and require minimal processing energy. Each cubic metre of bamboo used instead of traditional materials prevents roughly 1.5 tonnes of CO2 emissions.

The implementation of circular economy principles in material selection further amplifies these benefits. By choosing materials designed for recyclability, manufacturers can reduce waste-related emissions by up to 60%. Additionally, locally sourced sustainable materials decrease transport-related emissions, with some European manufacturers reporting logistics-related carbon reductions of 25-35% through strategic material sourcing.

Performance Comparison

When comparing eco-friendly materials with traditional options, performance metrics reveal encouraging results across multiple categories. Bamboo, for instance, demonstrates comparable strength-to-weight ratios to steel in certain applications while offering superior sustainability credentials. Recent studies show that bio-based plastics can match or exceed conventional plastics in durability tests, with some variants showing improved heat resistance and flexibility.

Natural fibre composites have proven particularly impressive in automotive and construction applications, delivering up to 40% weight reduction compared to glass-fibre alternatives while maintaining structural integrity. Cork-based materials showcase exceptional thermal and acoustic insulation properties, often outperforming synthetic alternatives by 10-15% in controlled testing environments.

Recycled materials have also made significant strides. Advanced recycled aluminium exhibits identical mechanical properties to virgin aluminium while reducing energy consumption by up to 95%. Similarly, recycled polyester fabrics now match virgin polyester in strength and durability tests, with some manufacturers achieving superior moisture-wicking capabilities through innovative processing techniques.

However, it’s important to note that performance can vary based on specific applications. While some eco-materials may require more frequent replacement in certain conditions, their overall environmental impact remains significantly lower. The key lies in selecting the right eco-friendly material for each specific use case, considering both performance requirements and environmental benefits in the decision-making process.

European Innovation in Sustainable Solar Materials

Research Breakthroughs

European research institutions have made significant strides in developing next-generation eco-friendly materials for sustainable manufacturing. Notable breakthroughs include a biodegradable polymer developed by scientists at the Technical University of Munich, which combines agricultural waste with mushroom-based compounds to create durable packaging materials that decompose within months.

Swedish researchers have pioneered a revolutionary wood-based transparent material that could replace traditional plastics in electronics and consumer goods. This cellulose-derived alternative offers comparable strength to conventional plastics while being fully biodegradable.

In the Netherlands, materials scientists have developed a self-healing bioplastic that extends product lifespans by automatically repairing minor damage. This innovation significantly reduces waste and replacement needs across various industries.

French laboratories have successfully created a new composite material using recycled carbon fibers and bio-based resins, achieving a 70% reduction in carbon footprint compared to traditional composites while maintaining superior strength properties. These advances demonstrate Europe’s leading role in sustainable materials innovation and its commitment to circular economy principles.

Industry Implementation

Leading European manufacturers have successfully integrated eco-friendly materials into their production processes, demonstrating remarkable results. Companies like SolarTech GmbH in Germany have replaced traditional glass substrates with recycled alternatives, reducing their carbon footprint by 40% while maintaining optimal performance standards. Their sustainable manufacturing practices have set new industry benchmarks.

In Sweden, Eco-Panel Solutions has pioneered the use of bio-based encapsulants, eliminating harmful chemicals from their production line. This innovation has not only enhanced product sustainability but also improved panel durability by 25%. Similarly, Dutch manufacturer GreenSolar has implemented a closed-loop system for silicon recycling, recovering 95% of materials from end-of-life panels.

These implementations have proven that eco-friendly materials can deliver superior performance while reducing environmental impact. The success of these initiatives has inspired a wave of innovation across the European solar industry, with smaller manufacturers following suit and adapting these practices to their operations.

The future of eco-friendly materials in solar panel production represents a pivotal shift towards truly sustainable energy solutions. As European manufacturers continue to innovate, we’re witnessing the emergence of biodegradable components, recycled materials, and non-toxic alternatives that significantly reduce the environmental impact of solar technology production.

The integration of these sustainable materials is already showing promising results, with several European facilities reporting reduced carbon footprints while maintaining high-efficiency standards. This transformation extends beyond environmental benefits, as eco-friendly materials often contribute to improved panel longevity and enhanced performance in varying weather conditions.

Looking ahead, research indicates that the adoption of sustainable materials in solar panel production will likely accelerate, driven by both consumer demand and stringent European environmental regulations. Manufacturers are investing heavily in developing new composite materials that combine durability with environmental responsibility, setting new industry standards for sustainable production.

The role of eco-friendly materials will become increasingly crucial as the solar energy sector expands. These innovations not only support the transition to renewable energy but also address the full lifecycle impact of solar technology. From reducing manufacturing waste to facilitating end-of-life recycling, sustainable materials are essential for creating a truly circular economy in the solar industry.

This evolution in material science demonstrates that environmental responsibility and technological advancement can work in harmony, paving the way for a more sustainable energy future.

Leave a Reply