The Core Materials Behind Modern Solar Panels: A Sustainability Deep-Dive

Modern solar panels harness the power of sunlight through a sophisticated combination of essential solar panel materials, with silicon leading the charge as the primary component. These technological marvels represent a careful balance of efficiency, durability, and sustainability, transforming sunlight into clean electricity through layers of precisely engineered materials.

At their core, solar panels combine high-grade silicon cells, protective glass, conductive metals, and specialized polymers. Each material serves a crucial role: silicon crystals convert photons into electrons, silver conductors channel the electricity, tempered glass shields against environmental factors, and polymer sheets provide essential insulation and protection.

As Europe accelerates its transition to renewable energy, understanding these fundamental building blocks becomes increasingly important for homeowners and businesses alike. Recent innovations in material science continue to push the boundaries of solar efficiency, promising even more sustainable and cost-effective solutions for our energy future.

Silicon: The Foundation of Solar Technology

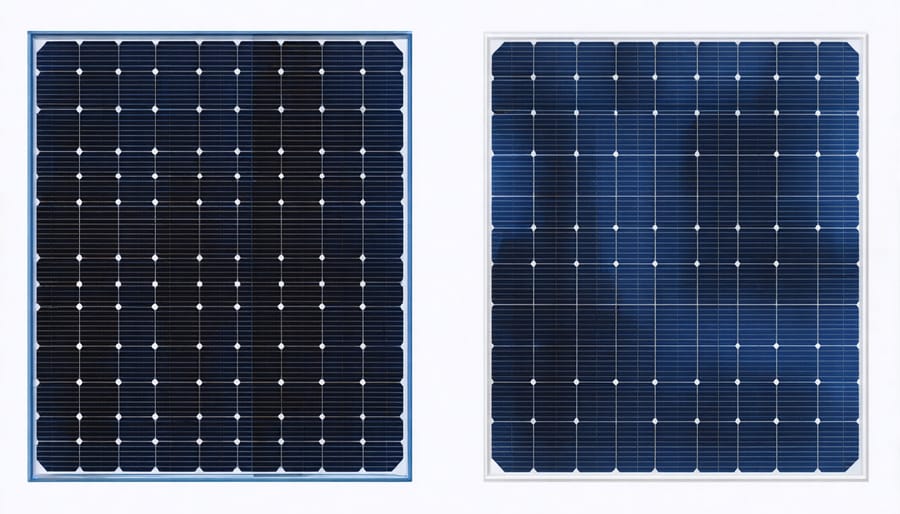

Monocrystalline vs. Polycrystalline Silicon

Silicon-based solar panels come in two main varieties: monocrystalline and polycrystalline, each offering distinct advantages for different applications. Monocrystalline panels, crafted from single silicon crystals, are known for their superior efficiency of solar panels and sleek black appearance. These panels excel in limited space installations and perform exceptionally well in European climates, particularly during overcast conditions.

Polycrystalline panels, manufactured by melting multiple silicon fragments together, offer a more cost-effective solution while maintaining reliable performance. Their distinctive blue hue results from the varied crystal formations within each cell. While slightly less efficient than their monocrystalline counterparts, polycrystalline panels present an excellent balance of performance and value, making them popular for larger installations where space isn’t a primary constraint.

Both variants demonstrate strong sustainability profiles, with manufacturing processes continuously evolving to reduce environmental impact. The silicon used in both types is abundant and recyclable, supporting the circular economy principles valued across European markets.

Silicon Purification: The Eco Challenge

The journey from raw silicon to solar-grade material presents significant environmental challenges that the industry actively works to address. Traditional purification methods require substantial energy input, with temperatures reaching up to 1,500°C in the initial processing stages. This energy-intensive process has historically contributed to the carbon footprint of solar panel production.

However, innovative developments in silicon purification are reshaping the landscape. European manufacturers are pioneering closed-loop systems that recycle chemical agents and reduce water consumption by up to 90% compared to conventional methods. Advanced filtration technologies now capture and repurpose silicon particles that would otherwise be lost during processing, improving material efficiency while reducing waste.

The industry is also exploring alternative purification methods, such as metallurgical-grade silicon refinement, which requires less energy and produces fewer emissions. These sustainable innovations, combined with increasing use of renewable energy in manufacturing facilities, are significantly reducing the environmental impact of silicon processing. This progress aligns with EU sustainability goals and strengthens the green credentials of solar technology.

Essential Metal Components

Silver and Aluminum: Conducting Solar Power

Silver and aluminium play crucial roles in the electrical conductivity of solar panels, forming the essential pathways that transport captured solar energy. Silver, primarily used in the form of conductive paste, creates a network of fine lines across the solar cells that efficiently collect and channel electrons. While silver offers superior conductivity, its rising costs have prompted manufacturers to optimize usage through innovative techniques like selective plating and thinner contact lines.

Aluminium, used in the panel’s frame and back sheet, provides both structural support and electrical conductivity at a more economical price point. The metal’s excellent conductivity-to-weight ratio makes it ideal for solar applications, while its corrosion resistance ensures long-term durability in outdoor conditions.

Sustainability concerns regarding silver mining have led to increased research into alternative materials and recycling processes. Modern recycling techniques can recover up to 95% of these metals from decommissioned panels, contributing to a more circular economy in solar manufacturing. European manufacturers are particularly focused on developing technologies that reduce silver content while maintaining optimal performance, balancing efficiency with environmental responsibility.

Frame Materials and Mounting Systems

Most modern solar panels feature robust aluminium frames that provide essential structural support while keeping the overall weight manageable. These frames protect the delicate solar cells and glass components while ensuring durability against various weather conditions common across European climates. The aluminium used is typically anodised to prevent corrosion and extend the panel’s lifespan to 25-30 years.

The mounting systems, crucial for proper installation, are predominantly made from aluminium and stainless steel components. These materials offer excellent strength-to-weight ratios and remarkable resistance to environmental factors. For roof installations, mounting rails and brackets use high-grade aluminium alloys, while ground-mounted systems often incorporate galvanised steel posts for enhanced stability.

From an environmental perspective, both aluminium and steel components are highly recyclable, supporting the circular economy principles valued in European markets. Manufacturers increasingly use recycled materials in frame production, reducing the carbon footprint of solar installations. Modern mounting systems also feature innovative designs that minimise material usage while maintaining structural integrity, further enhancing the sustainability profile of solar energy systems.

Glass and Encapsulation Materials

Advanced Glass Technologies

Recent advancements in glass technology have revolutionised solar panel efficiency and durability. Anti-reflective coatings now allow panels to capture more sunlight, reducing light reflection by up to 2.5%. Self-cleaning glass treatments, enhanced with hydrophobic properties, help panels maintain peak performance by preventing dust and debris accumulation.

European manufacturers have pioneered tempered glass innovations that are up to four times stronger than traditional glass while being 30% lighter. This development not only improves installation safety but also enables more flexible mounting options for both residential and commercial applications.

Smart glass technologies are emerging as game-changers, featuring electrochromic properties that respond to environmental conditions. These advanced glass solutions can automatically adjust their transparency to optimise energy absorption while protecting the underlying solar cells from excessive heat and UV exposure, potentially extending panel lifespan by 15-20%.

The integration of these glass technologies demonstrates the industry’s commitment to maximising solar energy efficiency while ensuring long-term reliability.

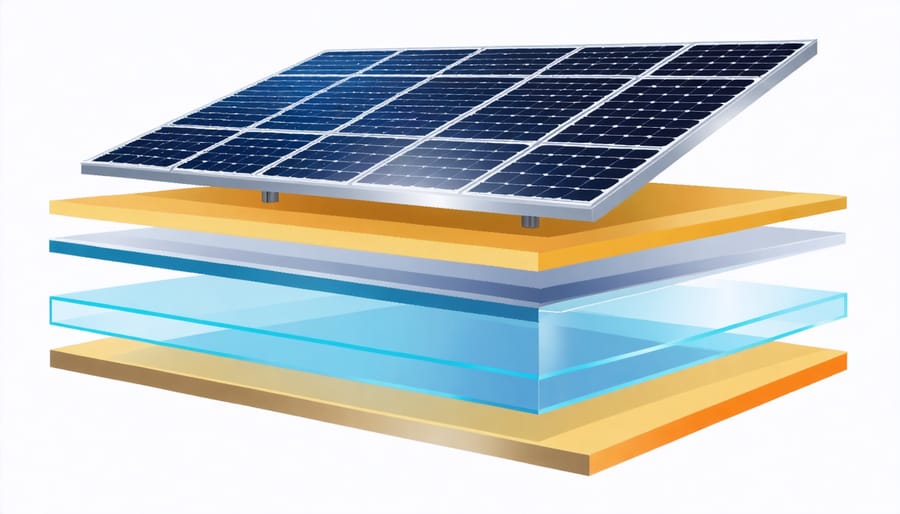

EVA and Backsheet Materials

EVA (Ethylene Vinyl Acetate) and backsheet materials serve as crucial protective layers in solar panels, safeguarding the delicate solar cells from environmental elements. EVA acts as a transparent adhesive layer, encapsulating the solar cells and ensuring optimal light transmission while preventing moisture infiltration. This durable material maintains its protective properties even under intense UV exposure and varying weather conditions.

The backsheet, typically made from multiple layers of polymeric materials, forms the outermost protective barrier on the panel’s rear side. Modern backsheets increasingly incorporate eco-friendly materials, reducing the environmental impact while maintaining durability. European manufacturers have pioneered the development of fluorine-free backsheets, which offer comparable performance to traditional materials while being more sustainable and easier to recycle.

These protective layers significantly influence a panel’s longevity, typically supporting a 25-30 year lifespan while ensuring consistent energy production throughout their operational life. Recent innovations focus on developing bio-based alternatives that maintain high performance standards while reducing the solar industry’s environmental footprint.

Emerging Eco-Friendly Alternatives

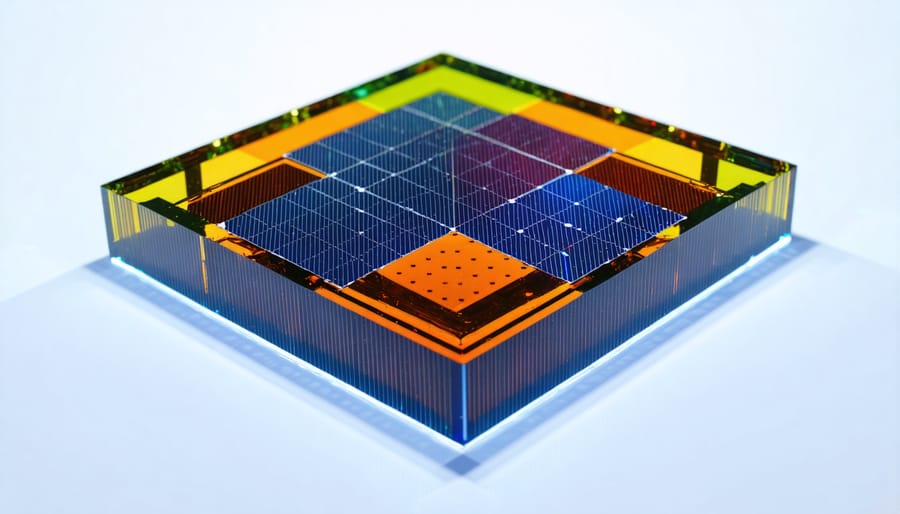

Perovskite Solar Cells

Perovskite solar cells represent one of the most exciting innovations in solar technology. These crystalline materials, named after Russian mineralogist Lev Perovski, have shown remarkable potential for revolutionising solar panel efficiency while reducing production costs. The unique crystal structure of perovskites allows them to absorb light more effectively than traditional silicon cells, with laboratory tests achieving efficiency rates above 29%.

What makes perovskites particularly promising for European solar manufacturing is their versatility and simpler production process. Unlike conventional silicon cells, perovskite materials can be produced using solution-based manufacturing methods, similar to printing ink on surfaces. This could significantly reduce production costs and energy consumption during manufacturing.

Another advantage is their potential for creating flexible and semi-transparent solar panels, opening new possibilities for building-integrated photovoltaics. Researchers across Europe are working on addressing stability and durability challenges, with significant progress being made in recent years. Some innovative approaches combine perovskites with traditional silicon cells in tandem configurations, potentially pushing overall solar cell efficiency beyond 30%.

While still in development, perovskite technology represents a promising path toward more efficient and cost-effective solar energy solutions for European homes and businesses.

Organic Solar Materials

As environmental concerns grow, researchers are developing innovative organic solar technology using biodegradable and sustainable materials. These emerging solutions utilize conductive organic polymers and carbon-based compounds instead of traditional silicon, offering promising alternatives for eco-conscious energy production.

Key organic materials include conjugated polymers, fullerenes, and organic small molecules that can convert sunlight into electricity. These components are typically processed using low-temperature methods and environmentally friendly solvents, significantly reducing the carbon footprint of manufacturing processes.

While current organic solar panels show lower efficiency rates compared to traditional silicon-based panels (typically 5-12%), they offer distinct advantages. Their flexibility, lightweight nature, and potential for semi-transparency make them ideal for building-integrated applications and innovative architectural designs. Moreover, their production requires less energy and generates minimal waste.

European research institutions are particularly focused on developing organic photovoltaic materials that combine improved efficiency with complete biodegradability. These materials aim to address end-of-life disposal concerns while maintaining the high performance standards expected in modern solar applications.

The materials used in solar panel production play a crucial role in shaping the future of renewable energy. As the European solar industry continues to evolve, manufacturers are increasingly focusing on sustainable material choices and innovative production methods. The shift towards more eco-friendly materials, such as lead-free alternatives and recycled silicon, demonstrates the industry’s commitment to reducing its environmental footprint while maintaining high performance standards.

Looking ahead, emerging technologies and materials promise even greater sustainability in solar panel production. Research into perovskites, organic photovoltaics, and advanced recycling techniques suggests a future where solar panels become both more efficient and environmentally responsible. The European Union’s commitment to renewable energy and circular economy principles further drives innovation in sustainable material selection.

For homeowners and businesses considering solar installation, understanding these material developments ensures informed decision-making that aligns with both environmental values and energy needs. As technology advances and production methods improve, we can expect solar panels to become increasingly sustainable, efficient, and accessible, contributing significantly to Europe’s clean energy transition.

Leave a Reply