Solar Thermal Systems Are Revolutionizing Mining Operations: Here’s How

As Europe accelerates its transition towards sustainable energy solutions, thermal solar technology emerges as a cornerstone of modern power generation, offering a remarkable 70-85% efficiency in converting sunlight into usable heat. Unlike traditional photovoltaic systems, solar thermal installations harness the sun’s infrared radiation to generate thermal energy, providing cost-effective solutions for industrial processes, district heating networks, and domestic hot water systems across the continent.

This proven technology has revolutionized energy consumption patterns in regions from Mediterranean Spain to Nordic Sweden, demonstrating exceptional versatility across diverse climatic conditions. By capturing and storing thermal energy in advanced heat transfer fluids, these systems deliver reliable performance even during periods of limited sunlight, addressing one of renewable energy’s greatest challenges: intermittency.

For industries and households alike, thermal solar energy represents a strategic investment in sustainable operations, offering significant reductions in carbon emissions while providing predictable energy costs for decades. With European energy prices continuing to rise and environmental regulations becoming increasingly stringent, solar thermal solutions provide a pragmatic pathway toward energy independence and environmental responsibility.

The Power of Solar Thermal Technology in Industrial Processes

How Solar Thermal Systems Generate Industrial Heat

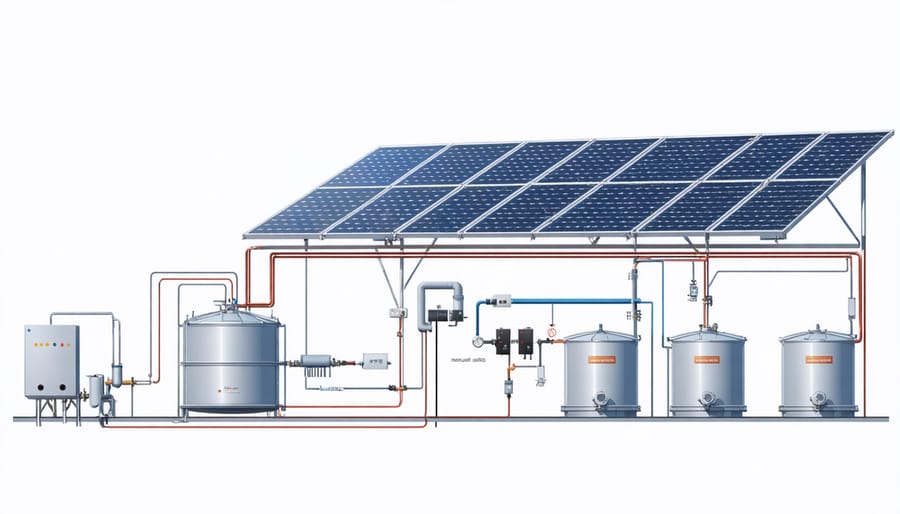

Modern solar thermal collection systems utilize advanced technology to capture and convert solar radiation into usable heat for industrial processes. These systems typically employ specially designed collectors, such as parabolic troughs or evacuated tubes, which concentrate sunlight onto heat-absorbing surfaces.

The process begins when sunlight strikes the collector’s surface, where a dark absorber coating transforms solar energy into heat. This thermal energy is then transferred to a heat-transfer fluid—usually water, oil, or molten salt—circulating through the system. The heated fluid moves through insulated piping to heat exchangers, where it releases its thermal energy to generate process heat or steam for industrial applications.

Advanced control systems optimize the collection and distribution of heat, maintaining consistent temperatures throughout the process. Storage tanks can retain excess thermal energy for use during non-sunny periods, ensuring continuous operation. The system’s modular design allows for scalability, enabling industries to expand their solar thermal capacity as needed while maintaining efficiency levels of up to 70% in ideal conditions.

Key Components of Industrial Solar Thermal Systems

Industrial solar thermal systems comprise several essential components working in harmony to harness and utilize solar energy effectively. At the heart of these systems are solar collectors, typically large-scale flat-plate or evacuated tube arrays, strategically positioned to maximize sun exposure. These collectors are integrated with sophisticated heat recovery and transfer systems that ensure optimal energy capture and distribution.

Storage solutions form another crucial element, usually consisting of well-insulated tanks that maintain heated fluid at consistent temperatures. These systems often incorporate thermal storage media, such as molten salts or phase-change materials, enabling continuous operation even during non-sunny periods.

The circulation system, comprising pumps, valves, and piping networks, ensures efficient heat transfer throughout the facility. Advanced monitoring and control systems maintain optimal performance through sensors, automated controls, and smart management interfaces. Heat exchangers facilitate the transfer of thermal energy between the collection circuit and process applications, while backup heating systems provide reliability during periods of low solar radiation.

Safety features, including pressure relief valves, expansion vessels, and emergency shutdown systems, complete these robust industrial installations.

Practical Applications in Mining Operations

Mineral Processing and Extraction

Solar thermal energy plays a crucial role in modern mineral processing and extraction operations, offering sustainable solutions for energy-intensive industrial processes. The high temperatures achieved through concentrated solar thermal systems provide an efficient means of processing various minerals and ores, reducing reliance on conventional fossil fuel-based heating methods.

In mineral processing applications, solar thermal technology is particularly valuable for operations requiring temperatures between 250°C and 1000°C. These systems can effectively support processes such as calcination, sintering, and ore preheating. For instance, in alumina production, solar thermal energy can maintain the necessary heat levels for bauxite processing, significantly reducing carbon emissions compared to traditional methods.

European mining operations have successfully implemented solar thermal solutions in various pilot projects. These installations typically utilize concentrated solar power (CSP) systems with specially designed receivers and heat transfer systems optimized for mineral processing requirements. The technology has shown promising results in reducing operational costs while advancing sustainability goals.

One notable advantage is the ability to integrate thermal storage systems, enabling continuous operation even during non-sunny periods. This feature makes solar thermal processing particularly attractive for mining operations in southern European regions, where solar resources are abundant. The technology also supports the European Union’s industrial decarbonization initiatives, offering a practical pathway for reducing the environmental impact of mineral processing operations.

Drying and Dewatering Operations

Solar thermal energy plays a crucial role in drying and dewatering operations across various European industries, offering sustainable solutions for moisture removal and material preparation. This application is particularly valuable in agricultural processing, where solar thermal systems efficiently dry crops, grains, and other agricultural products while maintaining product quality and reducing energy costs.

In industrial settings, solar thermal drying systems are increasingly used for dewatering processes in manufacturing, textile production, and waste management. These systems typically employ specially designed solar collectors that generate hot air or heated surfaces to remove moisture from materials effectively. The process is especially efficient during summer months when solar radiation is abundant, though modern systems can maintain effectiveness year-round through thermal storage solutions.

The technology has proven particularly successful in small to medium-sized enterprises across Europe, where it helps reduce dependency on conventional energy sources. For example, wood processing facilities use solar thermal drying to prepare timber, while food processing plants employ it for dehydrating fruits and vegetables. These applications not only lower operational costs but also contribute to reduced carbon emissions, aligning with EU sustainability goals and environmental regulations.

Water Treatment and Steam Generation

Solar thermal technology plays a crucial role in advancing sustainable water treatment solutions and steam generation processes across Europe. The system harnesses concentrated solar energy to heat water directly, making it particularly effective for industrial applications requiring high-temperature processes.

In water treatment applications, solar thermal collectors can achieve temperatures sufficient for desalination, purification, and sterilization processes. This approach significantly reduces energy costs while maintaining consistent treatment quality. The technology is especially valuable in regions where conventional energy sources are expensive or unreliable.

For steam generation, solar thermal systems can produce industrial-grade steam at temperatures ranging from 150°C to 400°C, ideal for manufacturing processes, district heating networks, and power generation applications. Modern installations typically incorporate thermal storage systems, ensuring continuous operation even during cloudy periods or after sunset.

The integration of solar thermal technology in water management systems offers both environmental and economic advantages, with potential energy savings of up to 70% compared to conventional heating methods. These systems demonstrate remarkable durability, often maintaining peak performance for 20-25 years with minimal maintenance requirements.

Economic and Environmental Benefits

Operational Cost Reduction

Implementing thermal solar energy solutions presents significant opportunities for cutting costs and carbon emissions across various sectors. Initial investment in solar thermal systems typically shows returns within 4-7 years, depending on scale and application. For residential installations, annual energy cost savings average between 50-70% on water heating expenses, while industrial applications can reduce process heat costs by up to 40%.

Maintenance costs for solar thermal systems are notably lower compared to conventional heating systems, requiring only annual inspections and minimal component replacement. The durability of modern solar thermal collectors, with lifespans exceeding 20 years, ensures long-term cost benefits. Additionally, many European countries offer attractive incentives, including tax rebates and grants, further improving the financial proposition.

Energy price volatility protection represents another significant advantage. By reducing dependency on traditional fuel sources, organizations and households can better predict and control their energy costs. Operating costs typically amount to just 1-2% of the initial investment annually, making solar thermal systems highly cost-effective over their lifetime.

The scalability of these systems allows for phased implementation, enabling businesses to manage investment costs while progressively expanding their solar thermal capacity. This approach helps optimize cash flow while steadily increasing energy independence and operational efficiency.

Carbon Footprint Reduction

Thermal solar energy systems significantly contribute to reducing carbon emissions by replacing conventional fossil fuel-based heating methods. A typical residential solar thermal installation in Europe can reduce CO2 emissions by 1.5 to 2 tonnes annually when used for water and space heating. For industrial applications, the impact is even more substantial, with large-scale systems potentially offsetting hundreds of tonnes of CO2 emissions each year.

The environmental benefits extend beyond carbon reduction. Solar thermal systems have minimal operational emissions, requiring only small amounts of electricity for pumps and controls. The energy payback period – the time needed for the system to generate the energy used in its production – is remarkably short, typically between 6 months to 2 years, depending on the installation size and location.

In the European context, solar thermal technology plays a crucial role in meeting EU climate targets. Countries like Germany, Austria, and Denmark have demonstrated that large-scale solar thermal districts can significantly reduce urban carbon footprints. For instance, Denmark’s solar district heating systems prevent approximately 15,000 tonnes of CO2 emissions annually per installation.

The sustainability metrics are particularly impressive when considering the system’s lifetime. With proper maintenance, solar thermal installations can operate efficiently for 20-25 years, delivering consistent environmental benefits throughout their operational life while requiring minimal resource input for maintenance and operation.

Implementation Challenges and Solutions

Technical Integration Considerations

Integrating thermal solar systems requires careful consideration of several technical factors to ensure optimal performance. The system’s orientation and tilt angle must be precisely calculated based on geographical location and local solar radiation patterns, typically ranging between 30-45 degrees in European latitudes. Proper sizing of storage tanks and collector arrays is crucial, with a general rule of thumb suggesting 1-1.5 square meters of collector area per person for domestic hot water systems.

Heat transfer fluid selection demands special attention, particularly in regions experiencing freezing temperatures. While water-glycol mixtures are common, innovative heat transfer fluids with enhanced thermal properties are emerging in the European market. The integration of control systems and monitoring equipment ensures efficient operation and helps prevent overheating during peak summer months.

System compatibility with existing infrastructure presents another crucial consideration. Retrofit installations may require additional components such as heat exchangers or buffer tanks to harmonize with conventional heating systems. Proper insulation of piping networks is essential, with modern materials offering thermal loss prevention rates of up to 90%.

Building regulations and load-bearing capacity must be evaluated, especially for roof-mounted installations. Professional installers should conduct thorough structural assessments and ensure compliance with local building codes. Regular maintenance access points should be incorporated into the design phase to facilitate system longevity and performance optimization.

Best Practices for Implementation

Successful implementation of thermal solar energy systems requires careful planning and adherence to established best practices. Begin with a thorough site assessment, considering factors such as available space, solar exposure, and local climate conditions. The optimal orientation for solar collectors in Europe is typically south-facing, with an inclination angle between 30-45 degrees for maximum efficiency.

System sizing must match your specific needs. For residential applications, calculate hot water consumption patterns and heating requirements before selecting equipment. Commercial installations should factor in peak demand periods and seasonal variations in energy needs.

Quality components are crucial for long-term performance. Choose certified collectors and storage tanks from reputable manufacturers that meet European standards. Ensure proper insulation of all piping and storage units to minimize heat loss and maintain system efficiency.

Professional installation by certified technicians is essential. They should follow manufacturer guidelines and local building regulations while implementing appropriate safety measures. Regular maintenance schedules should be established, including annual system inspections and periodic cleaning of collectors.

Integration with existing heating systems requires careful consideration of compatibility and control strategies. Modern building management systems can optimize the interaction between conventional heating and solar thermal components, maximizing energy savings.

For optimal results, implement monitoring systems to track performance and identify potential issues early. This data-driven approach enables timely adjustments and ensures the system operates at peak efficiency throughout its lifetime.

Solar thermal technology stands at the forefront of transforming mining and heavy industry operations across Europe and beyond. The demonstrated success in reducing carbon emissions while maintaining high-temperature industrial processes has positioned this technology as a crucial element in the sustainable future of energy-intensive industries. With proven energy cost reductions of up to 40% in various applications, solar thermal solutions are becoming increasingly attractive to forward-thinking businesses.

The integration of thermal storage systems has effectively addressed the intermittency challenges, enabling consistent operation beyond daylight hours. This breakthrough has particularly resonated with European industries striving to meet stringent environmental regulations while maintaining competitive advantages in the global market.

Looking ahead, emerging innovations in collector design and heat transfer fluids promise even greater efficiencies. Research indicates that next-generation solar thermal systems could achieve operating temperatures exceeding 1000°C, opening new possibilities for applications in metallurgy and chemical processing. The development of hybrid systems, combining solar thermal with other renewable technologies, suggests a future where industrial processes can be completely decarbonized.

As investment in research and development continues to grow, and with supportive EU policies driving adoption, solar thermal technology is poised to become a standard solution in mining and heavy industry. The transition to sustainable industrial processes is not just an environmental imperative but increasingly a commercial necessity, making solar thermal solutions an essential consideration for forward-thinking industrial operators.

Leave a Reply