Solar-Powered Robots Are Revolutionizing European Manufacturing (Here’s How)

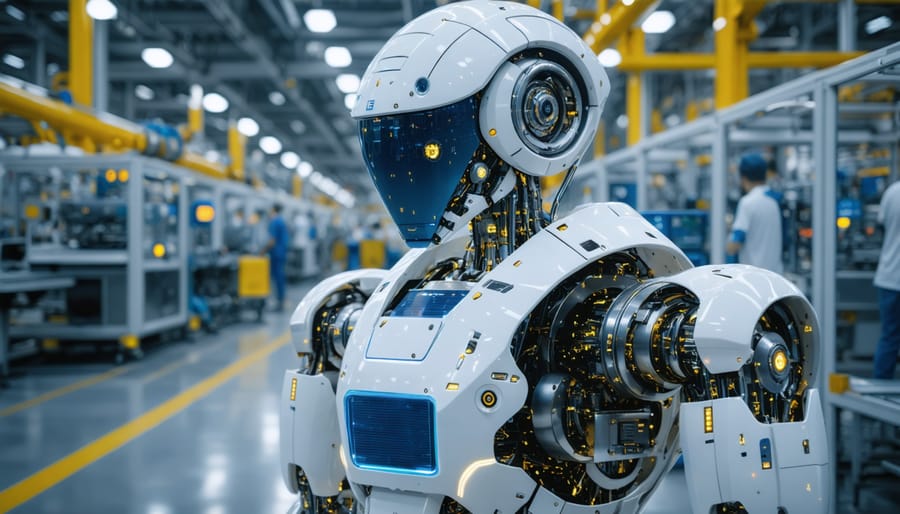

Solar robotics stands at the forefront of Europe’s industrial revolution, merging renewable energy with advanced automation to reshape manufacturing landscapes. These autonomous systems, powered by photovoltaic technology, represent a crucial advancement in sustainable industrial operations, reducing both carbon footprints and operational costs by up to 40%.

As industries across the EU accelerate their transition towards carbon neutrality, solar-powered robots are transforming everything from warehouse logistics to precision manufacturing. These innovative machines harness solar energy through integrated panels or dedicated solar farms, operating with remarkable efficiency while contributing to organizations’ environmental goals.

The convergence of solar technology and robotics addresses two critical challenges: reducing industrial energy consumption and optimizing automated processes. Modern solar robots demonstrate unprecedented adaptability, functioning reliably in various light conditions through advanced energy storage systems and intelligent power management algorithms. This technological synthesis not only enhances operational sustainability but also provides a compelling solution for industries seeking to maintain competitive advantages while meeting stringent EU environmental regulations.

The solar robotics sector, growing at an annual rate of 23% across Europe, showcases how renewable energy integration with automation technology creates smarter, more sustainable industrial operations for our future.

How Solar Robotics Transforms Industrial Manufacturing

Key Components of Solar-Powered Industrial Robots

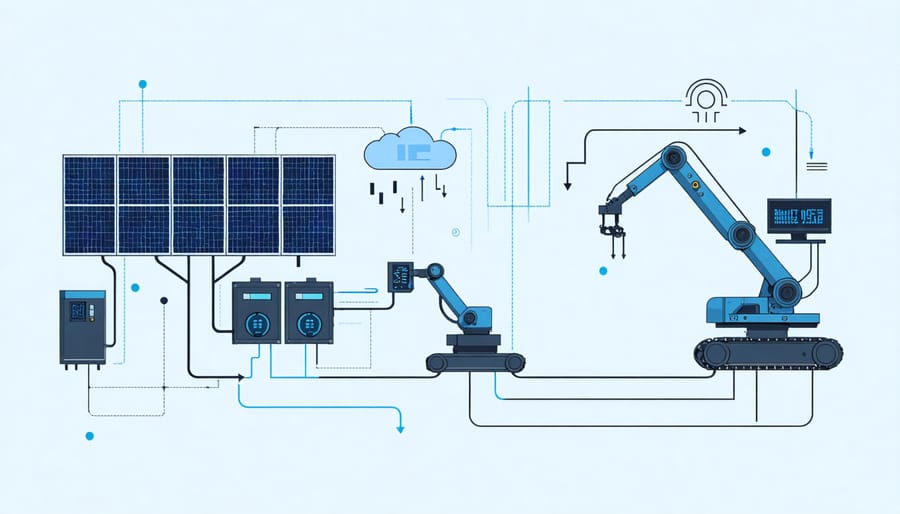

Solar-powered industrial robots integrate three essential components that work in harmony to deliver sustainable automation solutions. The foundation starts with high-efficiency photovoltaic arrays, specifically designed for industrial applications. These advanced solar panels utilize monocrystalline or polycrystalline technology, offering conversion rates of up to 23% and featuring smart tracking systems that optimize sunlight capture throughout the day.

Energy storage systems form the second crucial component, ensuring continuous operation even during low-light conditions. Industrial-grade lithium-ion batteries, combined with sophisticated power management systems, store excess energy during peak production hours. These systems are particularly vital in regions where solar thermal manufacturing applications must operate reliably despite varying weather conditions.

The robotic components themselves constitute the third key element, featuring energy-efficient motors, lightweight materials, and intelligent control systems. These robots incorporate precision sensors, advanced servo mechanisms, and adaptive programming capabilities that optimize power consumption while maintaining high performance. Modern designs emphasize reduced friction in joints and energy recuperation during deceleration phases.

The integration of these components relies on sophisticated control software that balances power availability with operational demands. Smart controllers continuously monitor energy levels, adjust robot behavior based on available power, and implement predictive maintenance protocols. This holistic approach ensures optimal energy utilization while maintaining consistent production output, making solar-powered robots increasingly viable for European manufacturing facilities committed to sustainable automation solutions.

Integration with Existing Manufacturing Systems

Integrating solar robotics into existing manufacturing environments requires careful planning and a systematic approach to ensure seamless compatibility with current industrial automation systems. Modern solar robotic solutions are designed with standardised communication protocols, including MODBUS, PROFINET, and OPC UA, enabling straightforward integration with prevalent factory management systems.

Key implementation considerations include power supply integration, data communication infrastructure, and physical space optimisation. Most contemporary solar robotic systems feature modular designs that allow for phased implementation, minimising disruption to ongoing operations. This approach enables manufacturers to gradually transition their facilities while maintaining productivity levels.

Compatibility assessment typically involves three primary stages: initial system audit, integration planning, and staged deployment. During the audit phase, existing infrastructure is evaluated for potential integration points and necessary upgrades. The planning stage focuses on developing customised solutions that align with current manufacturing workflows while preparing for future scalability.

Modern solar robotics platforms come equipped with advanced APIs and middleware solutions, facilitating connection with enterprise resource planning (ERP) systems and manufacturing execution systems (MES). This interconnectivity ensures real-time data exchange and enables comprehensive monitoring of both energy production and manufacturing processes, supporting informed decision-making and operational efficiency.

Environmental and Economic Benefits

Carbon Footprint Reduction

The integration of solar robotics represents one of the most impactful sustainable energy innovations for reducing industrial carbon emissions. Recent studies indicate that automated solar installation and maintenance systems can decrease the carbon footprint of solar projects by up to 27% compared to traditional methods. This reduction stems from multiple factors, including optimized installation efficiency, reduced transport requirements, and minimized human intervention during maintenance operations.

Quantitative analysis shows that robotic solar installations in European facilities achieve an average emissions reduction of 12.4 tonnes of CO2 per megawatt installed, primarily through precision placement and reduced material waste. The automated cleaning systems alone contribute to a 15% improvement in panel efficiency, translating to an additional carbon offset of 3.2 tonnes annually per installation.

Furthermore, the lifecycle assessment of solar robotics demonstrates that these systems help prevent approximately 42,000 kg of CO2 emissions over their operational lifespan through improved maintenance efficiency and extended solar panel longevity. This significant environmental impact positions solar robotics as a crucial tool in achieving Europe’s ambitious climate goals.

Long-term Cost Analysis

Initial investment in solar robotics systems typically ranges from €50,000 to €200,000, depending on scale and complexity. However, ROI analysis shows these systems often pay for themselves within 4-6 years through reduced operational costs and increased efficiency. European businesses implementing solar robotics report average energy cost reductions of 30-40% compared to traditional systems.

Maintenance costs for solar robotic systems average 1-2% of the initial investment annually, significantly lower than conventional automation systems requiring 3-5%. The longevity of modern solar tracking systems, typically 20-25 years, combined with decreasing component costs, creates a compelling long-term value proposition.

Performance data from existing installations across Europe demonstrates that automated solar systems increase energy yield by 20-35% compared to static installations. When factoring in government incentives and carbon credits available in various EU member states, the financial benefits become even more attractive.

Energy storage integration and smart grid capabilities further enhance cost advantages, with some facilities reporting additional savings of €5,000-15,000 annually through optimized energy management and reduced peak demand charges.

Real-World Applications in European Industry

Across Europe, innovative solar-powered manufacturing solutions are revolutionizing traditional industrial processes. In Stuttgart, Germany, automotive manufacturer Daimler has implemented robotic solar panel cleaning systems across their 40,000-square-meter facility, resulting in a 25% increase in energy generation efficiency and reducing water consumption by 80%.

The Netherlands’ agricultural sector showcases another compelling example, with the GrowBot initiative in Westland utilizing solar-powered robots for precision farming in greenhouse operations. These autonomous systems manage climate control, irrigation, and crop monitoring while running entirely on renewable energy, cutting operational costs by 35%.

In Barcelona’s logistics hub, automated guided vehicles (AGVs) powered by solar energy handle warehouse operations for major retailers. These robots, equipped with advanced sensors and AI capabilities, operate 20 hours daily using stored solar power, demonstrating how industrial automation can align with sustainability goals.

Sweden’s manufacturing sector has embraced solar robotics through the implementation of collaborative robots (cobots) in electronics assembly. These systems, powered by rooftop solar installations, work alongside human operators while maintaining zero carbon emissions during operation. The initiative has reduced energy costs by 40% while maintaining consistent production levels.

These implementations showcase how European industries are successfully integrating solar robotics to enhance operational efficiency while meeting sustainability targets. The technology’s adaptability across different sectors demonstrates its potential for widespread industrial application, particularly in regions with strong environmental policies and innovation support systems.

Implementation Challenges and Solutions

While solar robotics offers significant benefits, implementing these systems presents several key challenges that require careful consideration and strategic solutions. One primary obstacle is the initial system integration, particularly when retrofitting existing solar installations with robotic components. To address this, modular designs and standardised interfaces have been developed, allowing for smoother integration across different solar array configurations.

Weather resistance poses another significant challenge, as robotic systems must operate reliably in various environmental conditions. European manufacturers have responded by developing robust weatherproofing solutions and implementing predictive maintenance protocols that anticipate potential issues before they affect performance.

Power management remains crucial, as robotic systems need consistent energy supply to function effectively. Modern solutions incorporate efficient battery systems and smart power management algorithms that optimise energy consumption during operation. Some systems even utilise their own solar panels to maintain self-sufficiency.

Navigation accuracy across large solar fields can be problematic, especially in varying light conditions. Advanced positioning systems combining GPS, computer vision, and sensor fusion technologies have emerged as effective solutions, ensuring precise movement and operation even in challenging conditions.

Cost considerations often present barriers to adoption. However, innovative financing models and clear ROI demonstrations have helped businesses overcome initial hesitation. Many European suppliers now offer comprehensive support packages, including installation, training, and maintenance services, making implementation more accessible and manageable for organisations of all sizes.

Solar robotics stands at the forefront of Europe’s renewable energy revolution, combining cutting-edge automation with sustainable power generation. As we’ve explored, these innovative systems are transforming how we maintain and optimize solar installations across the continent, delivering enhanced efficiency and reduced operational costs. The integration of AI-driven robots, automated cleaning systems, and smart monitoring solutions has proven instrumental in maximizing solar energy yield and extending panel lifespan.

Looking ahead, the future of solar robotics appears exceptionally promising. Emerging technologies in machine learning and IoT connectivity are set to further enhance the capabilities of these systems, while decreasing implementation costs make them increasingly accessible to businesses of all sizes. European manufacturers and research institutions continue to lead development in this field, with new innovations focusing on improved energy efficiency and environmental sustainability.

For businesses and homeowners considering solar installations, the adoption of robotic solutions represents not just an investment in current operations, but a strategic step toward future-proof energy management. As the technology continues to mature, we can expect even more sophisticated applications that will further revolutionize how we harness solar power, ultimately contributing to Europe’s clean energy targets and sustainable industrial development.

Leave a Reply