Solar Panel Testing: How European Labs Ensure Your Panels Deliver Peak Performance

Testing solar panels represents a critical intersection of quality assurance and renewable energy performance, where precision meets sustainability. Modern testing procedures have evolved into sophisticated processes that determine not only immediate functionality but also long-term reliability and return on investment.

In Europe’s rapidly expanding solar market, rigorous testing protocols safeguard both manufacturers and consumers, ensuring panels meet strict IEC standards and deliver optimal performance across diverse climate conditions. From flash testing that measures power output to thermal cycling that simulates decades of weather exposure, each evaluation phase builds confidence in solar technology’s role in our sustainable future.

As solar installations continue to grow across European rooftops and commercial facilities, understanding testing methodologies becomes increasingly vital for stakeholders throughout the supply chain. Whether examining electroluminescence for micro-cracks or conducting load-bearing tests for extreme weather conditions, these assessments form the foundation of reliable solar energy systems that can perform consistently for 25+ years.

This comprehensive approach to quality control, combining laboratory precision with real-world performance metrics, ensures that European solar installations meet both current requirements and future energy demands while maintaining the highest standards of safety and efficiency.

Essential Performance Tests for Solar Panels

Power Output and Efficiency Testing

Power output and efficiency testing of solar panels primarily occurs under two standardized conditions: Standard Test Conditions (STC) and Nominal Operating Cell Temperature (NOCT). These testing environments help determine real-world performance expectations and have contributed to remarkable solar panel efficiency improvements over the years.

STC testing takes place in controlled laboratory settings at 25°C with an irradiance of 1000W/m² and an air mass of 1.5. This standardized approach allows for consistent comparison between different solar panels but may not fully reflect real-world conditions. Manufacturers use specialized solar simulators and precise measurement equipment to evaluate maximum power output, voltage, and current characteristics.

NOCT testing provides a more realistic performance assessment by simulating outdoor conditions. Testing occurs at 20°C ambient temperature with 800W/m² irradiance and wind speeds of 1m/s. These parameters better represent typical installation environments across European climates, offering valuable insights into actual energy generation potential.

During both tests, sophisticated monitoring equipment measures key performance indicators including:

– Maximum power output (Pmax)

– Open-circuit voltage (Voc)

– Short-circuit current (Isc)

– Fill factor (FF)

– Temperature coefficients

Results from these standardized tests enable consumers and installers to make informed decisions while ensuring compliance with European quality standards and certification requirements.

Durability and Environmental Testing

Solar panels must withstand diverse environmental conditions throughout their operational lifetime, making comprehensive durability testing standards essential for quality assurance. These tests simulate real-world conditions that panels encounter during their 25+ year lifespan.

Weather resistance testing exposes panels to accelerated weathering cycles, including UV radiation, rain, and humidity chambers. These tests evaluate the degradation of materials, particularly the protective glass coating and sealants, ensuring long-term performance in various European climates.

Thermal cycling tests subject panels to extreme temperature variations, typically ranging from -40°C to +85°C. This process reveals potential weaknesses in solar cell connections, module lamination, and frame integrity. European manufacturers typically conduct 200 to 400 cycles to verify panel resilience across seasonal temperature changes.

Mechanical load testing simulates wind and snow loads by applying uniform pressure to both panel surfaces. Static loads of up to 5400 Pascal test structural integrity, while dynamic load tests evaluate resistance to wind gusts and accumulated snow weight. This is particularly relevant for installations in Alpine regions and coastal areas where extreme weather conditions are common.

Additional tests include hail impact resistance, where panels must withstand ice balls of specified sizes at terminal velocity, and salt mist exposure for coastal installations. These rigorous testing protocols ensure that solar panels maintain their efficiency and structural integrity throughout their operational lifetime.

Quality Assurance Through Safety Testing

European Safety Standards

In the European Union, solar panel testing adheres to stringent standards established by the International Electrotechnical Commission (IEC). The IEC 61215 and IEC 61730 certifications form the cornerstone of these requirements, ensuring both performance and safety across all photovoltaic installations. These standards encompass comprehensive weather performance testing and durability assessments.

European manufacturers must comply with additional requirements, including the CE marking, which demonstrates conformity with health, safety, and environmental protection standards. The Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive also play crucial roles in ensuring solar panels meet EU safety specifications.

Key testing parameters under European standards include:

– Mechanical load resistance (snow and wind pressure)

– Temperature cycling tolerance (-40°C to +85°C)

– Humidity-freeze cycling

– Hot-spot endurance

– UV exposure resistance

– Salt mist corrosion resistance

The European Solar Test Installation (ESTI) facility, operated by the Joint Research Centre, provides independent verification of these standards. Their testing procedures ensure that solar panels maintain optimal performance while meeting safety requirements throughout their expected lifetime.

For installers and consumers, these certifications offer assurance of product quality and long-term reliability. Documentation of successful testing must be readily available and typically includes detailed performance data, safety compliance certificates, and quality assurance reports. This comprehensive approach to testing helps maintain the high standards expected in the European solar energy market while promoting innovation and sustainable development.

Electrical Safety Testing

Electrical safety testing is a crucial phase in solar panel validation that ensures both optimal performance and user safety. This process begins with insulation resistance testing, where technicians apply high voltage between the panel’s active circuits and frame to verify there’s no current leakage. For European installations, this test typically follows IEC 61215 standards, requiring panels to maintain insulation resistance above 40 MΩ under standard test conditions.

Grounding continuity tests verify that the panel’s frame and mounting system maintain proper electrical connection to earth. This essential safety measure protects against electric shock hazards and ensures compliance with European safety regulations. Technicians measure the resistance between various points on the frame and grounding terminals, which should not exceed 0.1Ω for optimal safety.

Hot spot testing identifies potential areas where solar cells might experience localised heating due to partial shading or cell defects. During this test, panels undergo controlled exposure to simulated partial shading conditions for extended periods, typically 1-3 hours. Thermal imaging cameras detect any abnormal temperature rises that could indicate potential failure points or safety risks.

Modern testing facilities employ automated systems that perform these safety checks systematically, recording detailed data for certification purposes. For European installations, panels must pass all electrical safety tests to receive CE marking and other relevant certifications. Regular retesting of installed systems is recommended, particularly after extreme weather events or when performance issues are noticed, to maintain safety standards throughout the system’s operational life.

These rigorous electrical safety protocols protect both the installation and its users while ensuring long-term reliability of the solar energy system.

Advanced Testing Technologies

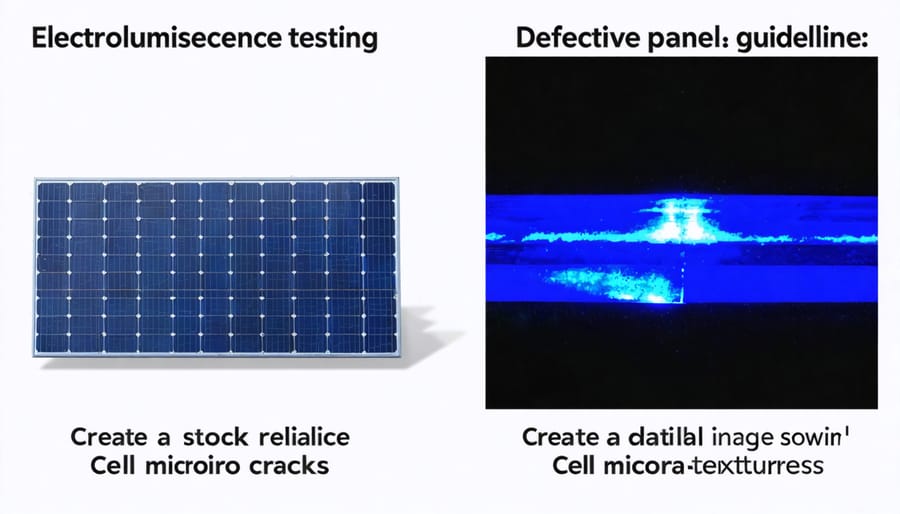

Electroluminescence Testing

Electroluminescence (EL) testing represents one of the most sophisticated methods for detecting solar panel defects, operating much like an X-ray for photovoltaic cells. During this innovative process, an electrical current is passed through the solar panel in a darkened environment, causing it to emit a faint glow. This luminescence is captured by specialized cameras, revealing hidden defects that might otherwise go unnoticed.

The resulting images provide detailed insights into cell integrity, showing microcracks, broken connections, and inactive areas that could impact performance. Dark spots in the image indicate potential issues, while uniformly bright areas suggest healthy, well-functioning cells. This precision testing method is particularly valuable for quality control in manufacturing and for assessing damage in installed systems.

For European solar installations, EL testing has become increasingly important due to strict quality standards and the growing emphasis on long-term system reliability. The test can identify manufacturing defects, transportation damage, and installation-related issues, helping ensure optimal system performance and longevity.

Professional testing facilities across Europe use this technology to verify panel quality before installation and diagnose issues in existing systems. For property owners and businesses, EL testing provides valuable documentation for warranty claims and maintenance planning, offering peace of mind about their solar investment’s condition and performance potential.

UV Fluorescence and Thermal Imaging

UV fluorescence and thermal imaging represent cutting-edge diagnostic techniques that have revolutionised solar panel testing across Europe. These non-invasive methods offer detailed insights into panel conditions that might otherwise go undetected through conventional testing approaches.

UV fluorescence testing utilises ultraviolet light to reveal microscopic cracks and defects in solar cells. When exposed to UV light, damaged areas emit a distinctive glow, helping technicians identify potential failure points before they impact performance. This innovative approach is particularly valuable for detecting manufacturing defects and stress-induced damage that might compromise long-term panel efficiency.

Thermal imaging, conducted using sophisticated infrared cameras, creates detailed heat maps of operational solar panels. These thermal scans identify hot spots, which often indicate electrical inefficiencies or faulty cells. During peak sunlight hours, properly functioning solar cells should display uniform temperature patterns. Any anomalies in these patterns can signal various issues, from damaged bypass diodes to delamination problems.

Modern testing facilities combine these technologies with automated analysis systems, enabling precise documentation of panel conditions. This comprehensive approach helps maintain quality standards across European solar installations while supporting warranty claims and maintenance planning. Regular thermal and UV inspections have become essential components of preventive maintenance programmes, helping ensure optimal system performance throughout the panel’s lifetime.

Quality Control in Manufacturing

Quality control during solar panel manufacturing involves a comprehensive series of tests and inspections conducted at various production stages to ensure optimal performance and reliability. Modern facilities employ automated quality control systems that continuously monitor and verify product quality throughout the manufacturing process.

The production line begins with incoming material inspection, where raw materials undergo rigorous testing for purity and specifications. Silicon wafers are examined for microscopic defects, thickness uniformity, and electrical properties. During cell fabrication, electroluminescence imaging detects micro-cracks and other imperfections that could affect performance.

In-line testing includes real-time monitoring of critical parameters such as cell efficiency, electrical conductivity, and mechanical strength. Advanced vision systems inspect solar cells for proper alignment, soldering quality, and precise ribbon placement. Each panel undergoes multiple checkpoints where specialized equipment measures:

– Layer thickness and uniformity

– Cell interconnection quality

– Glass surface integrity

– Frame assembly precision

– Junction box attachment

– Lamination quality

Final quality assurance involves flash testing to measure power output under standardized conditions, ensuring each panel meets its rated specifications. Panels also undergo thermal cycling tests to verify durability and performance stability under varying temperature conditions.

European manufacturers particularly focus on compliance with IEC standards and local certification requirements. Documentation and traceability systems record test results throughout the production process, enabling complete quality histories for each panel manufactured.

This systematic approach to quality control helps maintain consistency across production batches while reducing defect rates and ensuring long-term reliability. For European consumers and businesses, these rigorous testing procedures translate into more dependable solar installations and better return on investment.

Comprehensive testing of solar panels stands as a cornerstone of renewable energy reliability and investment protection. Through rigorous quality assurance processes, from flash testing to thermal imaging and mechanical load assessments, we ensure that solar installations meet the highest European standards while delivering optimal performance throughout their operational lifetime.

The impact of thorough testing extends far beyond initial certification. It directly influences system efficiency, maintenance requirements, and long-term return on investment. For European homeowners and businesses, properly tested solar panels typically demonstrate enhanced durability, consistent power output, and superior resistance to environmental stressors, ultimately leading to more sustainable energy production.

Testing also plays a crucial role in innovation and industry advancement. As solar technology continues to evolve, testing protocols adapt to address new challenges and opportunities, ensuring that emerging solutions meet both current standards and future requirements. This dynamic approach to quality assurance helps drive the continuous improvement of solar technology while maintaining unwavering safety and performance standards.

By prioritising comprehensive testing procedures, stakeholders can confidently invest in solar solutions that deliver reliable, efficient, and sustainable energy generation. The combination of standardised testing protocols and customised performance assessments creates a robust framework for solar panel quality, supporting Europe’s transition towards a cleaner, more sustainable energy future.

Leave a Reply