How Long Will Your Solar Inverter Really Last? The Complete Lifecycle Guide

Modern solar inverters typically last 10-15 years, serving as the critical link between your photovoltaic panels and usable electricity. Understanding their lifespan is essential for effective solar system lifecycle management and investment planning. While premium European models can function reliably for up to 20 years with proper maintenance, environmental factors and usage patterns significantly impact longevity. Temperature fluctuations, installation quality, and power load management directly affect inverter performance and durability. Recent technological advances, particularly in smart monitoring and thermal management, have enhanced inverter reliability while maintaining the strict European efficiency standards. For system owners, this means balancing initial investment against long-term performance, with modern inverters offering improved durability and sophisticated self-diagnostic capabilities that help predict and prevent potential failures.

Average Lifespan of Modern Solar Inverters

String vs. Microinverter Lifespans

String inverters and microinverters demonstrate notable differences in their operational lifespans, with each type offering distinct advantages. Microinverters typically showcase impressive longevity, with an average lifespan of 20-25 years, often matching the warranty period of solar panels themselves. This extended durability stems from their distributed architecture, which reduces stress on individual components.

String inverters, while equally reliable, generally operate effectively for 10-15 years before requiring replacement. However, modern string inverters incorporate advanced cooling systems and robust components that can extend their operational life beyond these estimates, particularly in optimal installation conditions.

The variation in lifespan can be attributed to several factors. Microinverters operate individually, converting DC to AC at each panel, which distributes the workload and heat generation. String inverters, managing multiple panels simultaneously, handle greater power loads but benefit from simpler maintenance procedures and lower initial costs.

European certification standards and quality requirements ensure both types maintain high performance throughout their operational life, making either choice viable depending on specific installation needs and environmental conditions.

European Quality Standards Impact

European manufacturing and quality standards significantly influence solar inverter longevity through rigorous certification processes and strict performance requirements. The IEC 62109 safety standard and the EN 50549 grid connection requirements ensure that inverters meet exceptional quality benchmarks before entering the European market.

Manufacturers must demonstrate compliance with electromagnetic compatibility (EMC) standards and environmental testing protocols, including resistance to temperature variations, humidity, and electrical stress. These requirements typically result in more robust components and superior build quality, contributing to extended operational lifespans.

The European Ecodesign Directive further promotes sustainability by mandating minimum efficiency requirements and design features that facilitate repairs and upgrades. This approach has led to innovations in thermal management and component selection, helping European-certified inverters achieve typical lifespans of 10-15 years, with premium models often exceeding these figures.

Additionally, European warranty standards provide comprehensive coverage, reflecting manufacturer confidence in product durability. This combination of stringent manufacturing standards and warranty protection has established European certification as a globally recognized mark of quality in solar inverter production.

Key Factors Affecting Inverter Lifespan

Environmental Conditions

Environmental conditions play a crucial role in determining the lifespan of solar inverters. Temperature is perhaps the most significant factor, with most inverters operating optimally between 20°C and 40°C. When exposed to temperatures outside this range, particularly during Europe’s increasingly warm summers, inverters may experience accelerated wear and reduced efficiency.

Humidity levels also significantly impact inverter longevity. In coastal regions or areas with high rainfall, excessive moisture can lead to corrosion of internal components and electrical connections. This is particularly relevant for outdoor installations in Northern European countries where rainfall is frequent.

The installation location itself can make or break an inverter’s lifespan. Inverters installed in well-ventilated, shaded areas typically last longer than those exposed to direct sunlight or installed in confined spaces with poor airflow. For instance, installing an inverter in an unventilated attic could reduce its lifespan by several years due to heat accumulation.

Dust and pollution levels in the installation environment also affect performance and longevity. Urban installations might require more frequent maintenance due to increased particulate matter, while rural installations generally face less environmental stress. Protection from these elements through proper mounting and housing can significantly extend an inverter’s operational life.

To maximise lifespan, European installers typically recommend mounting inverters in protected areas with good ventilation, away from direct sunlight and weather exposure. This approach aligns with both manufacturer guidelines and practical experience in the field.

Maintenance and Care

Regular maintenance is crucial to maximize inverter longevity and ensure optimal performance of your solar power system. Start with monthly visual inspections of your inverter, checking for dust accumulation, unusual sounds, or warning lights on the display panel. Clean the cooling fins and ventilation areas every three to six months, depending on your local environment, using a soft brush or compressed air.

Monitor your inverter’s performance through its display or monitoring system regularly. Any unexpected drops in energy production or efficiency should be investigated promptly. Keep the area around the inverter well-ventilated and free from obstruction, maintaining the recommended clearance specified in your manual.

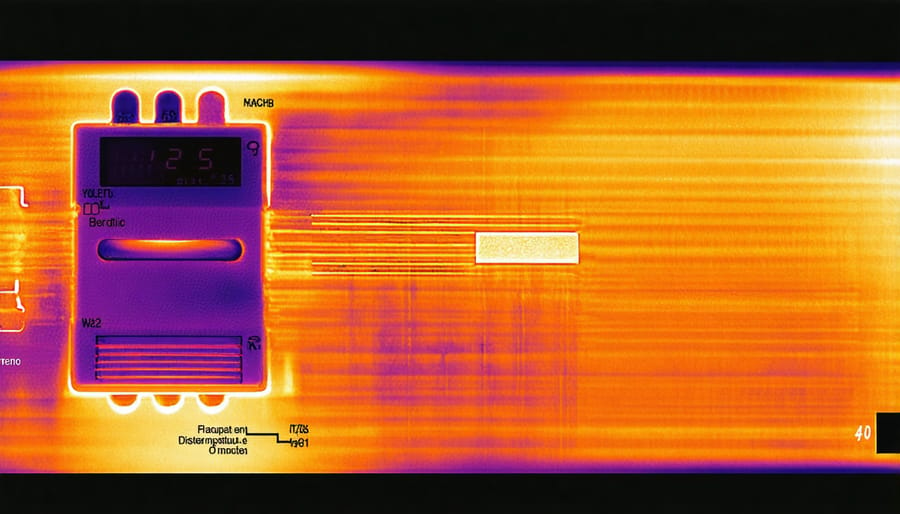

Professional maintenance checks are recommended annually. These inspections should include thermal imaging to detect potential hotspots, verification of all electrical connections, and software updates when available. During these checks, technicians can also assess the DC/AC conversion efficiency and compare it with baseline measurements.

For installations in coastal areas or industrial zones, more frequent cleaning may be necessary due to salt air or pollutants. Consider installing additional weather protection if your inverter is exposed to harsh environmental conditions. Document all maintenance activities and keep records of performance data – this information can be valuable for warranty claims and identifying potential issues early.

Signs of Inverter Aging and When to Replace

Common Warning Signs

Being proactive in identifying warning signs can help prevent unexpected inverter failures. Watch for decreased energy production shown on your monitoring system, as this often indicates declining inverter performance. Unusual noises, such as buzzing or humming that differs from normal operation, should prompt immediate attention. Pay attention to warning lights or error messages on the display panel, particularly those indicating grid voltage issues or internal faults.

Physical signs like discoloration around component connections, swollen capacitors, or rust formation suggest potential internal damage. If your inverter frequently disconnects from the grid or struggles to maintain stable power output, especially during peak sunlight hours, this could indicate deteriorating components.

Rising operating temperatures beyond manufacturer specifications or the need for more frequent restarts are also red flags. Modern inverters typically log performance data, so regular checks of efficiency metrics can reveal gradual decline. Any significant increase in conversion losses or decrease in power quality parameters warrants professional inspection to prevent complete failure and optimize your system’s performance.

Replacement Planning

Proactive planning inverter replacement is crucial for maintaining continuous solar system performance. Industry experts recommend starting replacement preparations when your inverter reaches 8-10 years of operation, even if it’s still functioning well. This allows sufficient time to research new technologies, compare options, and secure necessary funding.

Budget-wise, set aside approximately 15-20% of your initial solar system cost for inverter replacement. Modern inverters typically cost between €800-€2,000 for residential systems, while commercial installations may require €5,000-€15,000 or more, depending on capacity. Consider that newer models often offer improved efficiency and smart features that can offset the investment through enhanced performance.

When planning the replacement timeline, factor in seasonal considerations. Schedule installations during periods of lower solar production to minimize energy loss. Many European installers offer pre-booking discounts for planned replacements, which can help reduce costs. Additionally, check if your region provides any incentives or tax benefits for upgrading to more efficient inverter models as part of sustainability initiatives.

Sustainable End-of-Life Management

As solar inverters reach the end of their operational life, implementing responsible disposal practices becomes crucial for environmental sustainability. The European Union’s WEEE (Waste Electrical and Electronic Equipment) directive provides clear guidelines for the disposal and recycling of solar inverters, ensuring these devices are handled appropriately.

Most modern inverters contain valuable materials such as copper, aluminium, and electronic components that can be recovered and reused. Professional recycling facilities across Europe specialise in processing solar equipment, extracting these precious materials while safely disposing of potentially harmful elements.

To properly manage end-of-life inverters, owners should:

– Contact the manufacturer about their take-back programmes

– Consult certified waste management companies specialising in electronic equipment

– Document the disposal process for compliance and warranty purposes

– Consider upgrading to more efficient models when replacement is necessary

Many leading inverter manufacturers now incorporate eco-design principles, making their products easier to disassemble and recycle. This approach, combined with the growing network of specialised recycling facilities, helps minimise environmental impact while maximising resource recovery.

For commercial installations, developing an end-of-life management plan early is essential. This should include budgeting for disposal costs and identifying authorized recycling partners. Some regions offer incentives for proper disposal, making sustainable end-of-life management both environmentally and economically beneficial.

Remember that improper disposal can lead to environmental hazards and legal consequences. Always work with certified partners and maintain proper documentation throughout the disposal process.

Managing your solar inverter’s lifecycle is crucial for maximizing your renewable energy investment. With proper maintenance and regular monitoring, quality solar inverters can serve reliably for 10-15 years, providing optimal energy conversion efficiency throughout their lifespan. Remember that environmental conditions, installation quality, and maintenance practices significantly impact longevity. By following manufacturer guidelines, scheduling professional inspections, and implementing preventive maintenance measures, you can enhance your inverter’s performance and potentially extend its service life. When planning your solar installation, consider the inverter’s lifecycle costs and replacement timeline as part of your long-term energy strategy. This proactive approach not only ensures system reliability but also contributes to sustainable energy generation and reduced environmental impact, aligning with Europe’s renewable energy goals and maximizing your return on investment.

Leave a Reply