How Drones Are Revolutionizing Solar Panel Inspections Across Europe

Revolutionizing solar panel maintenance, drone inspection technology cuts inspection time by 90% while detecting thermal anomalies and micro-cracks with unprecedented precision. Advanced UAV systems equipped with thermal imaging cameras and high-resolution sensors now capture detailed panel diagnostics in minutes rather than hours, transforming how European solar facilities manage their assets. This technological leap enables facility managers to inspect vast solar arrays from above, identifying potential issues before they escalate into costly failures.

For solar installation professionals across Europe, drone-based inspections represent a quantum leap in efficiency and safety. Rather than risking technician safety with manual rooftop inspections, automated drones systematically map entire installations, generating comprehensive digital twins and detailed performance analytics. The resulting data helps optimize maintenance schedules, predict potential failures, and maximize energy yield through precise, data-driven decisions.

This innovation arrives at a crucial moment as Europe’s solar capacity continues its explosive growth, with inspection efficiency becoming increasingly critical for maintaining optimal performance across thousands of installations.

The Evolution of Solar Panel Inspection Methods

Traditional Inspection Challenges

Traditional solar panel inspection methods present significant challenges for facility managers and maintenance teams. Technicians must physically access rooftops or elevated installations, often in challenging weather conditions, to perform visual assessments and thermal analysis. This manual approach not only poses considerable safety risks but also requires extensive time and human resources.

The physical nature of traditional inspections means technicians must navigate potentially hazardous environments, including steep roofs and high-temperature surfaces. These conditions are particularly challenging during Europe’s diverse weather patterns, from intense summer heat to winter frost, which can make access even more dangerous.

Moreover, manual inspections are inherently time-consuming, requiring careful examination of each panel individually. This methodical approach often leads to increased operational costs and reduced efficiency. The human eye can also miss subtle defects or early signs of degradation, potentially allowing minor issues to develop into major problems that affect system performance.

For large-scale solar installations, traditional inspection methods become increasingly impractical, requiring multiple team members and extended periods to complete comprehensive assessments, ultimately impacting operational efficiency and maintenance schedules.

Drone Technology Advantages

Drone technology has revolutionised solar panel inspection processes, offering remarkable advantages over traditional methods. The most significant benefit is the dramatic reduction in inspection time, with drones capable of surveying large solar installations in hours rather than days. This efficiency translates into substantial cost savings for both operators and clients.

The precision of drone-based inspections is particularly noteworthy, as advanced thermal imaging cameras can detect minute defects that might be missed by human inspectors. These high-resolution thermal sensors identify hot spots, microcracks, and potential maintenance issues with exceptional accuracy, enabling proactive maintenance strategies.

Safety is another crucial advantage, as drones eliminate the need for technicians to work at heights or navigate potentially hazardous roof conditions. This aspect is particularly valuable for large-scale industrial installations where traditional inspections pose significant risks.

The comprehensive data collection capabilities of drones provide detailed documentation through high-quality imagery and thermal mapping. This digital documentation creates valuable baseline data for future comparisons and maintenance planning, supporting informed decision-making for solar asset management.

Advanced Drone Inspection Capabilities

Thermal Imaging Technology

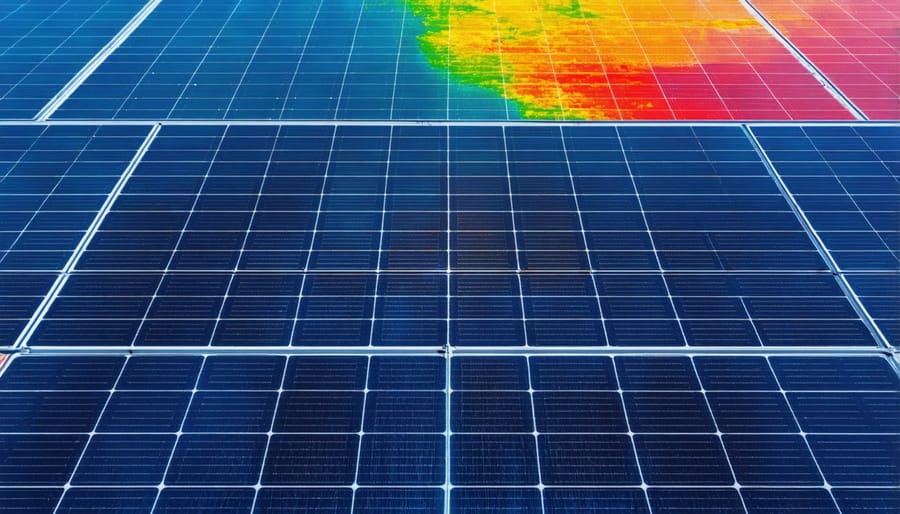

Thermal imaging technology serves as the cornerstone of modern drone-based solar panel inspections, enabling precise detection of panel defects that are invisible to the naked eye. These specialised thermal cameras mounted on drones capture infrared radiation emitted by solar panels, creating detailed heat maps that reveal potential issues through temperature variations.

When solar panels develop faults or inefficiencies, they typically generate excess heat in specific areas, known as hotspots. These thermal anomalies appear distinctly on infrared images, making it easy to identify problems such as faulty cells, connection issues, or internal defects. Modern drone-mounted thermal cameras can detect temperature differences as small as 0.5°C, ensuring even minor irregularities are caught early.

The technology works by comparing temperature patterns across the entire solar array. Healthy panels display uniform heat signatures, while problematic areas stand out as bright spots or irregular patterns. This capability is particularly valuable in European climates, where varying weather conditions can impact panel performance.

Advanced thermal imaging drones also incorporate radiometric technology, which provides precise temperature measurements for each pixel in the image. This data helps technicians assess the severity of issues and prioritise maintenance needs. Combined with automated analysis software, these systems can quickly process large amounts of thermal data, generating detailed reports that highlight potential problems and recommend specific maintenance actions.

AI-Powered Defect Detection

Modern drone inspection systems leverage sophisticated AI-powered solar panel monitoring algorithms to automatically detect and classify various defects in solar installations. These intelligent systems can identify microscopic cracks, hotspots, delamination, and potential induced degradation (PID) with remarkable accuracy.

The AI analyses thermal and visual imagery collected by drones, processing thousands of data points in minutes. This automated approach significantly reduces human error in defect detection while providing consistent, reliable results across large solar installations. The system learns from each inspection, continuously improving its accuracy through machine learning capabilities.

Advanced neural networks can now distinguish between genuine defects and harmless anomalies, such as bird droppings or temporary shadows, reducing false positives and unnecessary maintenance calls. The software generates detailed reports highlighting critical issues, their exact locations, and recommended actions, enabling maintenance teams to prioritise repairs effectively.

For European solar installations, this technology has proven particularly valuable in maintaining optimal energy production while adhering to strict regional maintenance standards and sustainability goals.

Real-time Data Collection

Real-time data collection represents one of the most significant advantages of drone-based solar panel inspection systems. As drones hover above solar installations, they transmit immediate data to ground stations, enabling technicians to analyse performance metrics and identify issues on the spot. This instant feedback dramatically reduces the time between detection and resolution of potential problems.

Modern inspection drones are equipped with advanced sensors that simultaneously gather multiple data points, including thermal imagery, visual recordings, and precise GPS coordinates. This comprehensive data collection allows maintenance teams to create detailed reports within hours rather than days or weeks, significantly improving operational efficiency.

The immediate availability of inspection data also enables quick decision-making and proactive maintenance scheduling. When a drone identifies a hotspot or panel degradation, facility managers can immediately prioritise repairs and allocate resources accordingly. This real-time capability is particularly valuable for large-scale solar installations across Europe, where swift identification of issues can prevent significant energy production losses.

Furthermore, the collected data can be automatically uploaded to cloud-based platforms, ensuring seamless sharing among stakeholders and creating a reliable digital record for future reference and trend analysis.

Implementation and ROI

Cost-Benefit Analysis

Implementing drone technology for commercial solar panel maintenance presents a compelling financial case when compared to traditional inspection methods. Initial investment typically ranges from €5,000 to €15,000 for a professional-grade drone system, including thermal imaging capabilities and specialized software.

The ROI calculation reveals significant cost savings. Traditional manual inspections of a 1MW solar installation typically require 2-3 technicians working for 3-4 days, costing approximately €2,000-€3,000 per inspection. In contrast, drone inspections can complete the same task in 4-6 hours with just one operator, reducing costs to €400-€600 per inspection.

Additional financial benefits include early fault detection, preventing potential energy losses worth thousands of euros annually. Drones can identify hotspots, micro-cracks, and other defects before they escalate into major issues. For a typical commercial installation, this preventative approach can save €3,000-€5,000 annually in repair costs.

Insurance premiums often decrease with drone implementation, as they reduce workplace safety risks. Companies report average premium reductions of 10-15%. The technology typically pays for itself within 12-18 months through combined savings in labour costs, increased efficiency, and reduced maintenance expenses.

These calculations are based on European market rates and demonstrate how drone technology transforms from a capital expense into a strategic investment for solar asset management.

Regulatory Compliance

Operating drones for solar panel inspection in Europe requires strict adherence to the European Union Aviation Safety Agency (EASA) regulations. Since December 2020, drone operations fall under a harmonised framework across EU member states, categorised into three risk levels: Open, Specific, and Certified categories.

For solar panel inspections, most operations fall within the Specific category, requiring operators to obtain operational authorisation from their national aviation authority. Drone pilots must complete certified training courses and obtain the appropriate Remote Pilot Certificate, which includes both theoretical knowledge and practical skills assessment.

Equipment requirements include drone registration with a unique identification number, appropriate insurance coverage, and compliance with technical specifications for the intended operation. Drones must also feature geo-awareness systems and remote identification capabilities.

Key compliance considerations include:

– Maintaining safe distances from people and properties

– Operating within Visual Line of Sight (VLOS) unless specifically authorised

– Adhering to local privacy and data protection regulations

– Following specific height and distance restrictions

– Maintaining detailed operation logs and maintenance records

For commercial solar inspection services, operators must also develop and maintain an Operations Manual detailing safety procedures, risk assessments, and emergency protocols. Regular updates to certifications and documentation are essential to maintain compliance with evolving regulations.

Future Developments

The future of drone-based solar panel inspection is rapidly evolving, with several groundbreaking innovations on the horizon. Artificial Intelligence (AI) and Machine Learning algorithms are becoming increasingly sophisticated, enabling drones to not only detect issues but also predict potential failures before they occur. These advancements help solar facility managers to maximize solar panel performance through predictive maintenance.

European researchers are developing autonomous drone swarms that can inspect large solar farms simultaneously, dramatically reducing inspection times and increasing efficiency. These systems will incorporate advanced thermal imaging capabilities with unprecedented resolution, allowing for the detection of micro-cracks and potential induced degradation (PID) at earlier stages.

Integration with Building Information Modeling (BIM) systems is another promising development, enabling seamless data flow between inspection results and facility management platforms. This integration will allow for automated maintenance scheduling and more precise ROI calculations for solar installations.

Emerging battery technologies are extending drone flight times, while new lightweight materials are improving their weather resistance and operational capabilities. The introduction of 5G networks across Europe will enable real-time data transmission and processing, making instant analysis and decision-making possible during inspections.

Additionally, manufacturers are developing specialized drone-mounted cleaning systems that can both inspect and maintain solar panels, addressing two critical maintenance needs in a single solution. These innovations, combined with evolving European regulations supporting drone operations, are setting the stage for more efficient and cost-effective solar asset management in the coming years.

The integration of drone technology in solar panel inspection represents a significant leap forward in renewable energy maintenance practices across Europe. By combining advanced imaging capabilities with automated inspection processes, drones have revolutionized how we monitor and maintain solar installations of all sizes. This transformation has resulted in faster inspections, enhanced safety protocols, and more accurate defect detection, ultimately leading to improved solar panel performance and longevity.

The cost-effectiveness and efficiency gains achieved through drone inspections have made solar energy systems more sustainable and economically viable for both homeowners and businesses. With reduced maintenance costs and minimized system downtime, solar installations can operate at peak efficiency, maximizing renewable energy generation and return on investment.

Looking ahead, the continued evolution of drone technology, coupled with artificial intelligence and machine learning capabilities, promises even more sophisticated inspection solutions. As Europe moves towards its renewable energy goals, drone-based solar panel inspection will remain a crucial tool in ensuring the effectiveness and reliability of solar installations, supporting the continent’s sustainable energy future.

Leave a Reply