Extending Solar Inverter Life: Smart Management of 3-Level Systems

Three-level inverters represent a groundbreaking advancement in power electronics, offering superior performance compared to traditional two-level systems through reduced harmonic distortion and enhanced efficiency. This innovative technology has become increasingly crucial in modern power applications, from renewable energy integration to industrial motor drives.

By utilizing three voltage levels instead of two, these inverters create a more refined output waveform that closely approximates a pure sine wave. This sophisticated approach results in lower switching losses, better power quality, and reduced electromagnetic interference – critical factors for both energy efficiency and equipment longevity.

The growing adoption of three-level inverters across Europe reflects their vital role in sustainable energy infrastructure. For industrial facilities and renewable energy installations, these systems provide the perfect balance between cost-effectiveness and performance, delivering up to 98% efficiency while maintaining stricter compliance with grid codes and environmental regulations.

As we navigate the transition toward cleaner energy solutions, three-level inverters stand at the forefront of power conversion technology, offering tangible benefits for businesses and utilities focused on optimizing their energy systems. Their ability to handle higher voltage levels while maintaining superior power quality makes them indispensable in modern power electronics applications.

Understanding 3-Level Inverter Technology

Key Components and Operation

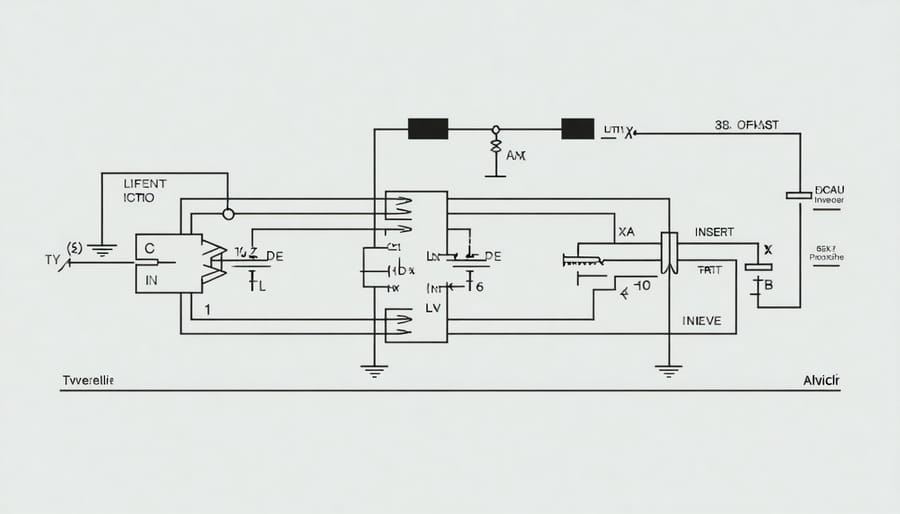

A 3-level inverter consists of several key components working in harmony to convert DC power into AC power more efficiently than traditional 2-level designs. At its core, the system utilizes multiple power semiconductor switches, typically IGBTs (Insulated Gate Bipolar Transistors), arranged in a specific topology. These switches work alongside specialized capacitors that create a neutral point, effectively dividing the DC bus voltage into three levels.

The operation relies on sophisticated switching patterns controlled by advanced algorithms. When converting DC to AC power, the system switches between three voltage levels: positive, negative, and zero. This creates a stepped waveform that more closely resembles a pure sine wave compared to traditional inverters. The neutral point clamping diodes ensure voltage balance and provide a stable reference point for switching operations.

The control system continuously monitors and adjusts switching patterns to maintain optimal performance while protecting components from voltage stress. This sophisticated control mechanism, combined with the three-level architecture, results in reduced harmonic distortion, better power quality, and improved overall efficiency – key benefits that make these inverters particularly valuable in European renewable energy installations.

Efficiency Benefits

The 3-level inverter technology represents a significant leap forward in solar energy conversion efficiency, offering substantial advantages over traditional 2-level inverters. By implementing an additional switching state, these advanced inverters achieve lower harmonic distortion and reduced switching losses, resulting in overall system efficiency improvements of up to 98.5%. This enhanced performance directly contributes to industrial carbon reduction efforts across Europe.

The improved efficiency manifests in several key areas. First, the reduced switching frequency leads to lower thermal stress on components, extending the system’s lifespan and reducing maintenance requirements. Second, the superior power quality output means less energy is lost during conversion, maximizing the return on investment for solar installations. Third, the smoother output waveform reduces electromagnetic interference, making these inverters particularly suitable for sensitive industrial applications.

For European businesses and homeowners, these efficiency gains translate into tangible benefits: lower operating costs, increased energy yield, and enhanced grid compatibility. The technology’s ability to handle higher voltage levels also makes it particularly valuable for large-scale solar installations, where even small efficiency improvements can yield significant energy savings.

Lifecycle Management Strategies

Preventive Maintenance

Regular preventive maintenance is crucial for ensuring the optimal performance and longevity of 3-level inverters. A well-structured maintenance schedule typically includes quarterly, bi-annual, and annual inspections. During quarterly checks, technicians should inspect cooling fans, air filters, and ventilation systems, ensuring they’re free from dust and debris. This is particularly important in European climates where seasonal changes can affect system performance.

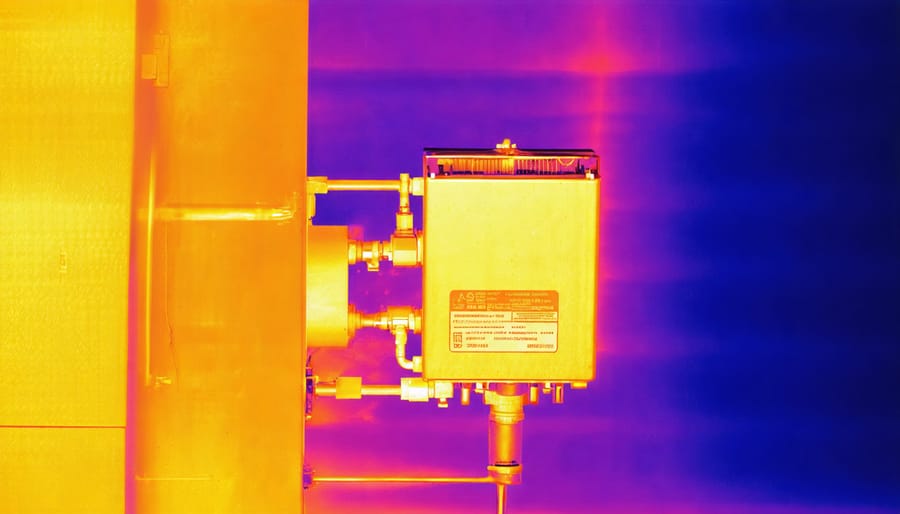

Bi-annual maintenance should focus on electrical connections, including the tightening of terminal connections and inspection of cable insulation. Thermal imaging can help identify potential hotspots before they become problematic. The DC and AC connection points require special attention, as loose connections can lead to energy losses and safety hazards.

Annual comprehensive maintenance should include:

– Testing of protection devices and safety systems

– Verification of control parameters and system settings

– Inspection of power semiconductor components

– Analysis of performance data and efficiency metrics

– Cleaning of heat sinks and cooling systems

– Verification of DC bus capacitors’ health

It’s recommended to maintain detailed maintenance logs and schedule interventions during low-production periods, typically early morning or evening hours. For industrial installations, consider implementing remote monitoring systems to track performance metrics and receive early warning of potential issues. This proactive approach helps prevent unexpected downtime and extends the inverter’s operational life while maintaining optimal efficiency levels.

Performance Monitoring

Modern 3-level inverters come equipped with sophisticated monitoring capabilities that help ensure optimal performance and early detection of potential issues. Advanced monitoring systems typically track key parameters including DC voltage levels, output power quality, switching patterns, and thermal conditions of critical components.

Real-time monitoring solutions often integrate smart sensors that continuously measure and analyse operational data. These systems can detect anomalies in switching patterns, identify unusual temperature fluctuations, and monitor power quality metrics such as total harmonic distortion (THD). Web-based monitoring platforms allow facility managers to access performance data remotely, enabling prompt response to any operational concerns.

Essential monitoring parameters include:

– Input and output voltage levels

– Phase current measurements

– Power factor

– Operating temperature

– Switching frequency stability

– Grid synchronisation status

Preventive maintenance tools have evolved to include predictive analytics capabilities, which use historical data and machine learning algorithms to forecast potential component failures before they occur. This proactive approach helps reduce downtime and maintenance costs while extending the inverter’s service life.

For European installations, monitoring systems typically include compatibility with regional grid codes and standards, ensuring compliance with local regulations while maintaining optimal performance. Many modern systems also feature automated reporting functions that generate periodic performance summaries, helping operators maintain detailed maintenance records and optimise system efficiency.

Common Issues and Solutions

While 3-level inverters are known for their reliability, users may encounter certain operational challenges. One common issue is uneven voltage distribution across DC-link capacitors, which can lead to reduced efficiency and potential component stress. This can typically be resolved by checking and recalibrating the voltage balancing control system or replacing worn capacitors.

Temperature-related problems may arise when cooling systems become compromised. Regular cleaning of heat sinks and ventilation channels, along with ensuring proper airflow around the inverter, can prevent overheating issues. If temperature alerts persist, professional inspection of the cooling system components is recommended.

Grid synchronisation issues occasionally occur, particularly following grid disturbances or maintenance. These manifest as connection failures or reduced power output. The solution often involves checking grid parameters and ensuring all protection settings are correctly configured according to local grid requirements.

Communication errors between the inverter and monitoring systems can disrupt performance tracking. These can usually be resolved by verifying network connections, updating firmware, or resetting communication modules. For persistent issues, consulting the manufacturer’s technical support is advisable.

Regular maintenance checks and prompt attention to warning signals can prevent most serious problems. It’s recommended to maintain detailed operation logs and schedule annual professional inspections to ensure optimal performance and longevity of your 3-level inverter system.

End-of-Life Considerations

Recycling Options

In Europe, the recycling of 3-level inverters follows established guidelines for solar inverter end-of-life management, ensuring sustainable disposal and resource recovery. Several specialized facilities across the continent are equipped to handle these sophisticated power electronics components.

The European Union’s WEEE (Waste Electrical and Electronic Equipment) directive provides a comprehensive framework for inverter recycling. Certified recycling centers in countries like Germany, France, and the Netherlands offer dedicated services for processing power electronics, recovering valuable materials such as copper, aluminum, and rare earth elements.

Many manufacturers have established take-back programs, partnering with local recycling facilities to ensure proper disposal. These programs typically include collection points at authorized service centers and direct pickup services for large installations. The recycling process involves systematic dismantling, with components sorted into categories: metals, circuit boards, capacitors, and plastic housings.

Modern recycling facilities employ advanced separation technologies to maximize material recovery rates, typically achieving up to 90% recovery of recyclable materials. Some facilities specialize in recovering precious metals from electronic components, while others focus on processing bulk materials like aluminum heat sinks and copper wiring.

For businesses and homeowners, local waste management authorities can provide detailed information about certified recycling partners and collection points in their region. Many recycling facilities also offer documentation for regulatory compliance and environmental reporting.

Environmental Impact

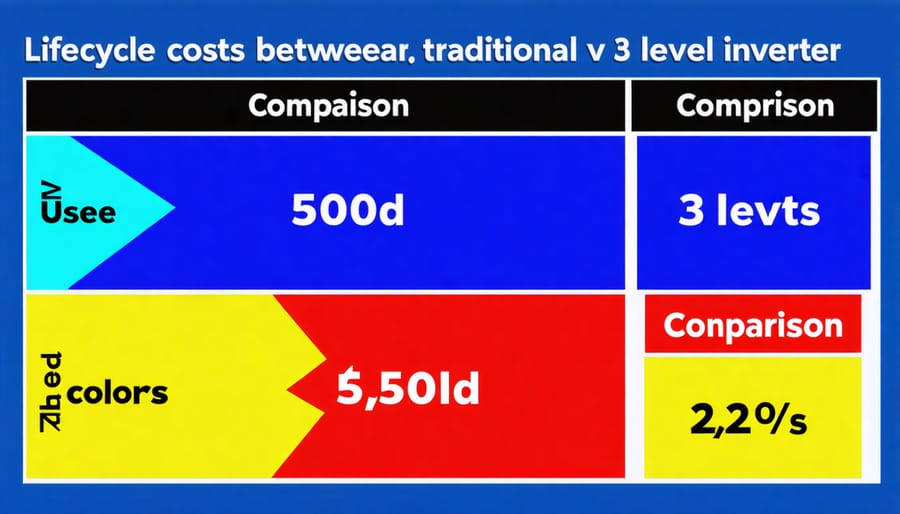

The environmental impact of 3-level inverters extends beyond their operational efficiency, playing a crucial role in sustainable energy systems. These inverters contribute to reduced carbon emissions through improved power conversion efficiency, typically achieving 2-3% higher efficiency compared to traditional 2-level inverters. This enhancement translates to significant energy savings over the system’s lifetime.

In terms of lifecycle management, 3-level inverters contain valuable materials that require proper handling during disposal. The European Union’s WEEE (Waste Electrical and Electronic Equipment) directive governs the disposal of such equipment, with specific guidelines for electronic components and semiconductor devices. Understanding these recycling costs and regulations is essential for facility managers and system operators.

The manufacturing process of 3-level inverters has also evolved to incorporate more environmentally friendly practices. Manufacturers are increasingly using lead-free solder and reducing harmful substances in compliance with RoHS (Restriction of Hazardous Substances) regulations. Additionally, modern designs focus on modularity, making components easier to replace and recycle, thereby extending the system’s useful life and reducing electronic waste.

The reduced electromagnetic interference (EMI) from 3-level inverters also contributes to a lower environmental impact, particularly in urban settings where electromagnetic pollution is a growing concern. This characteristic makes them particularly suitable for densely populated European areas where environmental standards are stringent.

Future-Proofing Your Investment

Upgrade Pathways

Modern 3-level inverter systems offer several upgrade pathways to enhance performance and extend operational life. For existing installations, firmware updates provide the most straightforward enhancement option, improving system efficiency and adding new smart monitoring capabilities without hardware modifications.

Hardware upgrades typically focus on power module replacement, incorporating latest-generation semiconductors that offer better thermal management and higher switching frequencies. These improvements can boost overall system efficiency by 1-2% while reducing operational temperatures and extending component lifespan.

Communication interface modernisation represents another valuable upgrade path, enabling integration with contemporary energy management systems and smart grid functionality. This enhancement particularly benefits European facilities aiming to participate in grid services or optimise energy consumption patterns.

For systems approaching their mid-life phase, comprehensive modernisation packages are available, combining multiple upgrades into a single intervention. These packages often include advanced monitoring systems, improved cooling solutions, and updated control algorithms, delivering a notable performance boost while maintaining the existing infrastructure.

Industrial users can opt for parallel system expansion, adding new inverter modules to increase power handling capacity. This modular approach allows for gradual system growth without requiring complete replacement, offering an economically efficient scaling solution that aligns with evolving energy needs.

Cost-Benefit Analysis

When evaluating the economic aspects of 3-level inverters, facility managers must carefully weigh maintenance costs against replacement expenses. Regular maintenance, while requiring ongoing investment, can significantly extend the equipment’s lifespan and maintain optimal performance, contributing to better sustainable energy ROI.

Maintenance costs typically include routine inspections, component replacements, and occasional repairs. These expenses are generally predictable and can be budgeted effectively. The average annual maintenance cost ranges from 1-2% of the initial investment, though this varies based on usage patterns and environmental conditions.

Complete replacement, while offering the advantage of updated technology and improved efficiency, represents a substantial capital expenditure. Current market prices for 3-level inverters, including installation, can range from €15,000 to €50,000 depending on capacity and specifications.

The optimal decision point often occurs when maintenance costs begin to escalate, typically around the 10-12 year mark. At this stage, if annual maintenance expenses exceed 8-10% of replacement costs, investing in new equipment becomes more economically viable. However, this threshold should be evaluated alongside factors such as system performance, energy efficiency gains from newer models, and potential regulatory requirements for modern equipment.

Innovation in inverter technology continues to drive down replacement costs while improving efficiency, making the replacement option increasingly attractive for aging systems.

The 3-level inverter represents a significant advancement in power conversion technology, offering enhanced efficiency and reliability for European solar energy systems. By understanding its operational principles, maintenance requirements, and lifecycle management, facility managers and system operators can maximise their investment while ensuring sustainable operations. Regular monitoring, preventive maintenance, and proper end-of-life handling are crucial for optimal performance and environmental responsibility. When planning for system upgrades or replacements, consider working with certified professionals who understand local regulations and can provide comprehensive support. Remember that proper maintenance not only extends system lifespan but also maintains high efficiency levels, ultimately contributing to a more sustainable energy future. By following these guidelines and staying informed about technological developments, you can ensure your 3-level inverter system continues to deliver reliable, efficient power conversion for years to come.

Leave a Reply