BESS Inverter End-of-Life: Smart Solutions for Your Solar Investment’s Future

BESS (Battery Energy Storage System) inverters represent a crucial advancement in modern energy management, transforming how we store and utilize renewable power. These sophisticated power conversion systems serve as the vital bridge between battery storage units and the electrical grid, enabling seamless energy flow optimization. As Europe accelerates its transition to renewable energy, BESS inverters have emerged as essential components for both residential installations and utility-scale projects, offering enhanced grid stability and energy independence.

The technology combines advanced power electronics with intelligent control systems to manage bidirectional power flow, ensuring efficient energy conversion while maintaining power quality standards. With capabilities ranging from basic battery charging to complex grid services, BESS inverters play a fundamental role in maximizing the value of energy storage investments. Their significance continues to grow as European nations strengthen their commitment to renewable energy integration and grid modernization, making them indispensable for sustainable energy future.

Understanding BESS Inverter Lifecycles

Key Components and Wear Patterns

The BESS inverter’s longevity depends largely on several critical components that require regular monitoring and maintenance. The power semiconductor modules, typically IGBTs or MOSFETs, often show the first signs of wear due to thermal cycling and switching stress. These components usually exhibit degradation after 8-10 years of operation, though this varies based on usage patterns and environmental conditions.

Capacitors represent another crucial wear point, with electrolytic capacitors being particularly susceptible to aging. Regular temperature monitoring can help predict potential failures, as capacitor life typically halves for every 10°C increase above rated temperature. Cooling systems, including fans and heat sinks, commonly show reduced efficiency over time due to dust accumulation and bearing wear.

Control boards and communication interfaces may experience reliability issues after 5-7 years, often manifesting as intermittent connectivity problems or reduced response times. The DC input terminals and AC output connections should be regularly inspected for signs of corrosion or loose connections, as these can lead to increased resistance and heat generation.

Understanding these wear patterns enables proactive maintenance scheduling and helps prevent unexpected system failures.

Performance Degradation Signs

Regular monitoring can help identify several key indicators that your BESS inverter may be approaching its end-of-life phase. Watch for decreased charging efficiency, where the battery takes longer to reach full capacity. Unusual noises, excessive heat generation, or visible physical deterioration of components are clear warning signs. Performance data showing consistent drops in conversion efficiency or increased error messages through your monitoring system should prompt immediate attention.

Pay attention to longer response times during peak demand periods and unexpected system shutdowns. Your inverter’s display panel may show error codes more frequently, or you might notice irregular voltage fluctuations. Modern BESS systems typically feature smart monitoring capabilities that can alert you to declining performance metrics before critical failure occurs.

Regular maintenance checks and performance data analysis can help predict potential issues, allowing for planned replacements rather than emergency interventions.

Sustainable Disposal Options

European Recycling Regulations

The European Union maintains strict regulations governing the recycling and disposal of battery energy storage systems (BESS) and their inverters. Under the WEEE Directive 2012/19/EU, manufacturers and importers must ensure proper collection and recycling of electronic components. The Battery Directive 2006/66/EC further mandates specific requirements for battery disposal and recycling, with recent updates emphasizing the importance of sustainable battery recycling solutions.

System owners must register their BESS installations and work with certified recycling partners when decommissioning equipment. The current framework requires a minimum recycling efficiency of 50% for most battery types, with higher targets for lithium-ion batteries used in BESS applications. Manufacturers are obligated to provide clear end-of-life instructions and establish take-back schemes.

Compliance involves proper documentation, authorized collection points, and certified recycling facilities. Non-compliance can result in significant penalties, making it essential for both installers and end-users to understand and follow these regulations throughout the system’s lifecycle.

Certified Recycling Partners

For environmentally responsible disposal of BESS inverter systems, several certified recycling partners across Europe provide specialized services compliant with WEEE regulations. Notable facilities include Veolia’s dedicated electronic waste centers in Germany and France, and Stena Recycling’s advanced processing plants in Sweden and Denmark. These partners employ state-of-the-art recycling technologies to recover valuable materials while ensuring proper handling of potentially hazardous components.

When selecting a recycling partner, look for facilities with ISO 14001 certification and specific authorization for handling battery energy storage systems. Leading manufacturers like SMA, Fronius, and Huawei maintain partnerships with these certified recyclers, offering convenient take-back programs for their customers.

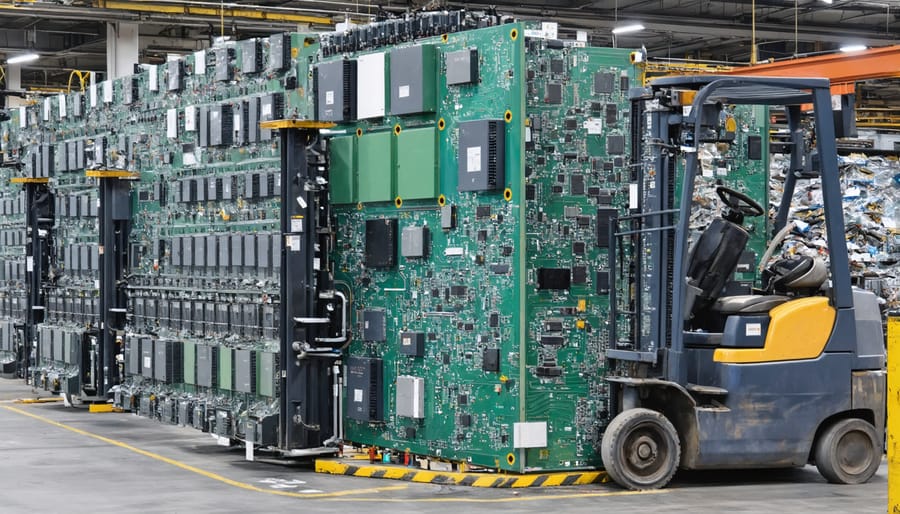

The recycling process typically involves systematic disassembly, material separation, and resource recovery, with up to 95% of components being recyclable. Metals such as copper, aluminum, and precious materials are extracted and reintegrated into the manufacturing supply chain, supporting circular economy principles.

For maximum environmental benefit and compliance, always work with authorized recycling partners who provide detailed documentation of the disposal process and certificates of destruction when required.

Maximizing Value Recovery

Reusable Components

Many components within BESS inverters can be successfully refurbished or reused, contributing to circular economy principles and cost reduction. The power electronic modules, including IGBTs and capacitors, often maintain their functionality after proper testing and reconditioning. Control boards and communication interfaces can typically be repurposed when maintained correctly, while cooling systems and fans are generally suitable for continued use after thorough cleaning and maintenance.

Transformers and inductors, being robust components, frequently outlast other parts and can be reintegrated into refurbished systems. The metal enclosures and mounting hardware usually remain serviceable for extended periods, requiring only minor repairs or surface treatments. Monitoring sensors and safety components can often be recalibrated and reused, provided they meet current safety standards.

For maximum sustainability, professional assessment of these components is essential to ensure they meet performance and safety requirements. European recycling facilities increasingly offer specialized services for evaluating and recertifying BESS inverter components, supporting both environmental responsibility and economic efficiency.

Material Recovery Process

The material recovery process for BESS inverters involves several sophisticated steps to maximize resource recovery. Initially, the system undergoes careful disassembly to separate electronic components from the housing. Valuable metals like copper, aluminum, and precious metals are extracted through mechanical separation and chemical processing. Circuit boards undergo specialized treatment to recover gold, silver, and rare earth elements. Advanced thermal processes help separate plastics from metals, while automated sorting systems ensure maximum material purity. The recovered materials are then refined and prepared for reuse in new manufacturing processes, supporting circular economy principles. This systematic approach helps recover up to 95% of materials from end-of-life BESS inverters, significantly reducing environmental impact while reclaiming valuable resources for future use in sustainable energy technologies.

Planning for Replacement

Cost Considerations

When planning a BESS inverter replacement, careful financial consideration is essential for maximizing energy investment ROI. Initial costs typically range from €2,000 to €8,000, depending on system capacity and specifications. However, this investment should be weighed against potential energy savings and improved system efficiency.

Additional expenses to consider include installation labour, system compatibility upgrades, and potential grid connection fees. Many European countries offer incentives and tax benefits for energy storage system upgrades, which can significantly offset replacement costs. It’s advisable to research available subsidies in your region and consider timing the replacement to align with these programs.

Maintenance contracts and extended warranties can add to the total cost but provide valuable long-term protection. Consider creating a replacement fund by setting aside a portion of your energy savings to prepare for future upgrades. This approach ensures financial readiness while maintaining system performance and reliability.

Technology Evolution

Recent years have witnessed remarkable advancements in BESS inverter technology, delivering enhanced efficiency and functionality for energy storage systems. Modern BESS inverters now achieve conversion efficiencies exceeding 98%, significantly reducing energy losses during storage and discharge processes. Smart grid integration capabilities have become standard features, enabling sophisticated energy management and seamless communication with utility networks.

The latest generation of BESS inverters incorporates advanced power electronics that support bi-directional power flow, faster response times, and improved power quality. Many models now feature modular designs, allowing for easier scaling and maintenance. Enhanced monitoring systems provide real-time performance data and predictive maintenance alerts through user-friendly interfaces.

Safety innovations include advanced thermal management systems, improved isolation mechanisms, and sophisticated fault detection algorithms. These developments have made BESS inverters more reliable and safer to operate, while also extending their operational lifespan and reducing maintenance requirements. The integration of artificial intelligence and machine learning capabilities enables optimal energy flow management and adaptive performance optimization.

Proper end-of-life management of BESS inverters is crucial for environmental sustainability and regulatory compliance in Europe’s evolving energy landscape. As these systems reach their operational limits, implementing structured decommissioning processes ensures valuable materials are recovered and hazardous components are handled safely. By planning ahead for replacement and recycling, system owners can maximize their investment while contributing to the circular economy. The growing focus on sustainable practices and stricter EU regulations makes it essential to partner with certified recycling facilities and maintain detailed documentation throughout the disposal process. Understanding and following these end-of-life procedures not only protects the environment but also helps maintain the reputation of renewable energy solutions as a truly sustainable choice for our energy future.

Leave a Reply