Roll-On Foam Insulation: The Future of Energy-Efficient Solar Panel Installation

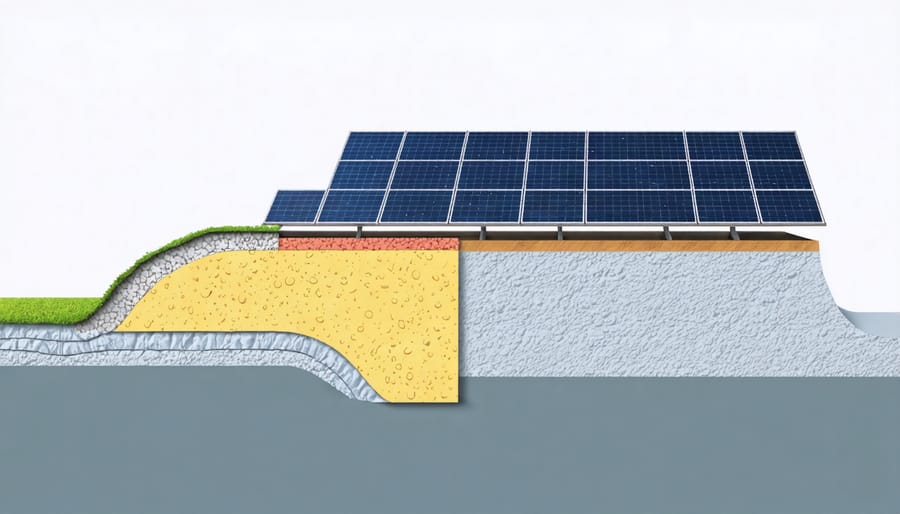

Roll-on foam insulation revolutionizes modern building efficiency by combining superior thermal performance with remarkably simple application methods. This innovative insulation solution expands up to 100 times its liquid volume upon application, creating an airtight seal that effectively blocks heat transfer and eliminates thermal bridges throughout building structures.

As Europe accelerates its transition toward energy-efficient construction, roll-on foam insulation emerges as a pivotal technology for achieving ambitious sustainability targets. Its unique ability to conform to irregular surfaces and penetrate hard-to-reach spaces makes it particularly valuable for both new construction and renovation projects, delivering R-values of 6.5 per inch while significantly reducing energy consumption and carbon footprints.

Professional contractors and DIY enthusiasts alike appreciate this insulation method’s versatility and ease of use. Unlike traditional insulation materials, roll-on foam creates a continuous barrier that simultaneously addresses air infiltration, moisture control, and thermal resistance – three critical aspects of building envelope performance. This comprehensive solution not only enhances building comfort but also contributes to substantial energy cost savings throughout the structure’s lifetime.

Understanding Roll Foaming Technology

Core Components and Materials

Roll-on foam insulation systems primarily consist of two key components: a polyurethane-based foam and a specialized catalyst that triggers the expansion process. These advanced foaming technology innovations create a robust thermal barrier when combined. The base foam material contains microscopic cells that, upon application, expand to create a seamless protective layer.

The formulation typically includes renewable materials and eco-friendly blowing agents that comply with European environmental standards. Modern compositions feature enhanced fire-retardant properties and moisture-resistant additives, ensuring long-term performance and safety. The catalyst component, usually supplied separately, contains reactive agents that initiate the chemical expansion process when mixed with the base material.

Additionally, primers and protective coatings may be included in the system to enhance adhesion and UV resistance. These supplementary materials are specifically engineered to work with the foam’s chemical composition, ensuring optimal performance across various temperature ranges and environmental conditions. The entire system is designed for compatibility with common construction materials while maintaining its insulating properties throughout its service life.

Application Process

The application of roll-on foam insulation follows a precise, methodical process to ensure optimal performance. First, the surface must be thoroughly cleaned and dried, removing any dust, debris, or moisture that could compromise adhesion. Professionals then apply a primer coat to enhance bonding and create an ideal surface for the foam.

The foam mixture is prepared according to manufacturer specifications, typically combining two components that activate the expanding properties. Using specialised spray equipment or roller tools, technicians apply the foam in even strokes, maintaining consistent thickness throughout. The application usually requires multiple layers, with each layer allowed to cure partially before the next is applied.

During application, ambient temperature and humidity levels must be closely monitored, as these factors significantly influence curing time and final performance. Proper ventilation is essential throughout the process. Once the final layer is applied, the foam requires a specific curing period, typically 24-48 hours, before any finishing work can commence.

Professional installers conduct quality checks throughout the process, measuring thickness and ensuring complete coverage without gaps or weak spots. This systematic approach guarantees optimal insulation performance and longevity.

Energy Efficiency Benefits

Thermal Management

Roll on foam insulation plays a crucial role in maintaining optimal temperature conditions for solar installations, directly contributing to solar panel efficiency improvements. The thermal management capabilities of this innovative solution work in two essential ways: preventing heat loss during colder months and reducing heat gain during warmer periods.

The foam’s closed-cell structure creates millions of tiny air pockets that effectively resist heat transfer, maintaining a stable temperature environment for solar components. This thermal stability is particularly valuable in European climates, where temperature fluctuations can significantly impact system performance.

When properly applied, roll on foam insulation maintains its thermal resistance properties throughout its lifetime, typically achieving R-values between 3.6 and 6.5 per inch. This consistent performance helps regulate operating temperatures, which is essential for maintaining optimal solar energy conversion rates.

The material’s seamless application ensures comprehensive coverage, eliminating thermal bridges that could compromise system efficiency. This complete thermal envelope helps protect sensitive components from extreme temperature variations, potentially extending equipment lifespan and maintaining peak performance levels throughout the year.

For installations in both residential and commercial settings, this thermal management solution provides year-round benefits, contributing to increased energy efficiency and improved return on investment for solar energy systems.

Energy Loss Prevention

Roll on foam insulation serves as a highly effective barrier against energy loss, delivering significant improvements in thermal performance across various building structures. The innovative technology creates a seamless, continuous layer that effectively seals even the smallest gaps and crevices, preventing thermal bridges that commonly occur with traditional insulation methods.

The foam’s expanding properties ensure complete coverage of irregular surfaces and hard-to-reach areas, establishing an airtight envelope that dramatically reduces heat transfer. This comprehensive coverage typically results in energy savings of 30-50% compared to buildings with conventional insulation systems, making it particularly valuable in regions with extreme temperature variations.

The technology’s effectiveness lies in its superior R-value per inch and its ability to maintain consistent performance over time. Unlike traditional insulation materials that can settle or deteriorate, roll on foam maintains its structural integrity and insulating properties throughout its lifetime. This durability ensures long-term energy efficiency and consistent climate control within the building.

Furthermore, the foam’s air-sealing properties prevent moisture infiltration, which not only protects the building structure but also enhances the overall energy efficiency by eliminating cold spots and reducing the workload on heating and cooling systems. This comprehensive approach to energy loss prevention makes roll on foam insulation a sustainable solution for modern construction and renovation projects.

Installation and Maintenance

Professional Installation Requirements

Professional installation of roll on foam insulation requires certified technicians with specific training in spray foam application techniques and safety protocols. Installers must possess valid certifications from recognised industry bodies and demonstrate thorough knowledge of building regulations and insulation standards.

The installation process demands precise environmental conditions, with ambient temperatures typically between 15-30°C and relative humidity below 80% for optimal application. Technicians must carefully prepare the substrate, ensuring surfaces are clean, dry, and free from contaminants that could compromise adhesion.

Personal protective equipment (PPE) is mandatory, including respiratory protection, protective suits, and safety goggles. The workspace requires proper ventilation systems and containment measures to control overspray and maintain air quality during application.

Installation teams must be equipped with professional-grade spray equipment, including proportioners, transfer pumps, and spray guns calibrated for the specific foam formulation. Regular equipment maintenance and calibration checks are essential for consistent application quality.

Documentation of installation parameters, including temperature readings, humidity levels, and material batch numbers, is required for quality assurance and warranty purposes. Post-installation inspection and thickness measurements ensure compliance with project specifications and building codes.

Long-term Maintenance

Roll-on foam insulation requires systematic maintenance to ensure its long-term effectiveness and durability. Annual inspections are essential to identify any potential issues early on. During these checks, focus on areas where the foam meets other materials, as these junction points can be susceptible to separation over time.

Monitor for any signs of physical damage, such as cracks or peeling, particularly in areas exposed to temperature fluctuations or mechanical stress. If you notice small damages, document their location and size to track any progression. Professional assessment is recommended every three to five years to evaluate the overall condition of the insulation system.

Keep the insulated surfaces clean and free from debris, as accumulated dirt can affect the material’s performance. In industrial settings, where the insulation might be exposed to chemicals or other harsh conditions, more frequent inspections may be necessary. Maintain proper ventilation in insulated spaces to prevent moisture-related issues.

Should repairs be needed, always use compatible materials and consult with qualified professionals. Proper maintenance records should be kept, including inspection dates, findings, and any remedial actions taken. This documentation helps track the insulation’s performance over time and supports warranty claims if needed.

European Standards and Compliance

Certification Requirements

Installation of roll on foam insulation in solar energy systems requires strict adherence to European testing standards and regulatory requirements. Installers must obtain certification from recognised industry bodies, including the European Organisation for Technical Assessment (EOTA) and relevant national authorities.

Key certification requirements include:

– Professional installer certification through accredited training programs

– Product compliance with EN 13165 for thermal insulation materials

– Fire safety certification according to EN 13501-1

– Environmental compliance with EU construction product regulations

– Quality management system certification (ISO 9001)

Installers must maintain updated certifications and regularly participate in continuing education programs to stay current with evolving industry standards. Documentation of proper installation techniques, safety procedures, and quality control measures is mandatory for project approval.

Professional liability insurance is also required, covering potential issues related to installation quality and performance. Regular audits ensure compliance with sustainability guidelines and energy efficiency standards, while proper documentation of material specifications and installation procedures must be maintained throughout the project lifecycle.

Environmental Impact

Roll on foam insulation represents a significant step forward in sustainable building practices, offering numerous environmental advantages over traditional insulation methods. The manufacturing process of this innovative material has a lower carbon footprint compared to rigid foam boards, particularly when considering the broader environmental impact of solar manufacturing and installation systems.

The spray application eliminates material waste typically associated with cut-to-fit solutions, as the foam can be precisely applied to exact specifications. This reduction in waste not only benefits the environment but also improves cost efficiency for installers and end-users. Additionally, the superior thermal performance of roll on foam insulation contributes to reduced energy consumption in buildings, leading to lower greenhouse gas emissions over the structure’s lifetime.

Modern formulations of roll on foam insulation often incorporate eco-friendly blowing agents and contain recycled content, further reducing their environmental impact. Many manufacturers now offer water-based solutions that emit minimal volatile organic compounds (VOCs) during application. The extended lifespan of foam insulation, often exceeding 25 years, means fewer replacement cycles and reduced material consumption over time, supporting long-term sustainability goals in the construction sector.

Roll-on foam insulation represents a significant advancement in solar installation technology, offering a compelling combination of thermal efficiency, durability, and ease of application. As European markets continue to embrace sustainable energy solutions, this innovative insulation method has positioned itself as a vital component in maximising solar system performance and longevity.

The benefits of roll-on foam insulation extend beyond its primary function of temperature regulation. Its seamless application process, superior adhesion properties, and ability to conform to various surface geometries make it an increasingly popular choice among solar installers and property owners. The material’s contribution to energy efficiency aligns perfectly with EU sustainability goals and growing environmental consciousness across the continent.

Looking ahead, the future of roll-on foam insulation appears promising. Ongoing technological developments are focusing on enhancing its thermal properties, environmental impact, and cost-effectiveness. Manufacturers are investing in research to develop formulations that offer even better performance while reducing environmental footprint. This continuous innovation, coupled with increasing demand for efficient solar installations, suggests a bright future for roll-on foam insulation in the renewable energy sector.

For European homeowners and businesses considering solar installations, roll-on foam insulation presents a forward-thinking solution that combines practical benefits with sustainable operations. As the solar industry evolves, this technology will likely play an increasingly crucial role in optimising installation efficiency and maintaining system performance across diverse climate conditions.

Leave a Reply