How Smart Solar Supply Chain Management Drives Project Success

The global solar supply chain stands at a critical intersection of technological innovation and sustainable energy transformation across Europe. From raw silicon procurement to final panel installation, this intricate network powers a €132.8 billion industry that’s reshaping our energy landscape. Yet with 80% of solar components currently manufactured in Asia, European stakeholders face unique challenges in securing reliable supplies, maintaining quality standards, and meeting growing demand.

As solar adoption accelerates—with the EU targeting 600GW of solar capacity by 2030—understanding and optimizing the supply chain becomes crucial for project success. Complex logistics, varying regulatory requirements across member states, and increasing pressure for local manufacturing create a dynamic environment that demands strategic management and forward-thinking solutions.

This complexity affects everyone from individual installers to large-scale developers, making supply chain expertise essential for project viability. Whether sourcing panels for a residential installation or coordinating components for utility-scale developments, mastering the solar supply chain’s intricacies determines not just project timelines and costs, but also long-term energy security and sustainability goals.

The future of Europe’s solar industry hinges on building resilient, efficient supply chains that can support ambitious renewable energy targets while fostering domestic manufacturing capabilities.

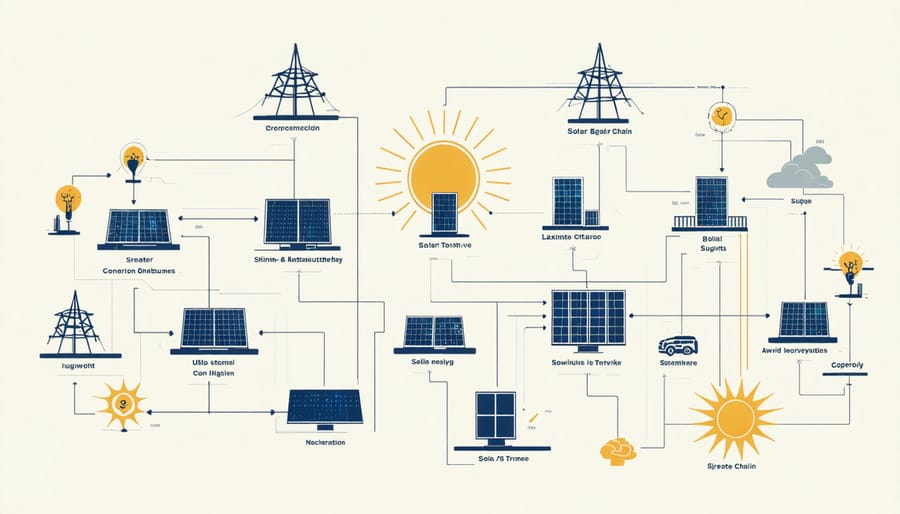

Key Components of the Solar Supply Chain

Raw Materials and Component Manufacturing

The foundation of the solar supply chain begins with the extraction and processing of essential raw materials. Silicon, the primary component in photovoltaic cells, undergoes extensive refinement from quartzite to achieve the ultra-pure polysilicon needed for solar applications. This refined silicon forms the basis of the solar panel manufacturing process, where it’s transformed into wafers and cells.

Beyond silicon, the industry relies heavily on various metals and materials. Aluminum frames provide structural support, while silver paste creates electrical contacts. Glass manufacturing facilities produce specialized tempered glass that optimizes light transmission while protecting the cells. Additionally, EVA (ethylene vinyl acetate) and backsheet materials ensure panel durability and weather resistance.

European manufacturers have increasingly focused on sustainable sourcing practices, implementing circular economy principles in their production processes. Many facilities now utilize renewable energy in their operations, reducing the carbon footprint of component manufacturing. Advanced automation and quality control systems ensure consistent output while minimizing material waste.

The component manufacturing stage involves multiple specialized facilities, each focusing on specific elements like inverters, mounting systems, and electrical components. This distributed manufacturing network helps maintain supply chain resilience while supporting local economies across Europe. Innovation in materials science continues to drive improvements in efficiency and sustainability throughout the production process.

Distribution and Logistics Networks

The efficient movement of solar components from manufacturers to installation sites relies on sophisticated distribution and logistics networks throughout Europe. These networks comprise specialized transportation services, strategic warehouse locations, and coordinated delivery systems designed to handle delicate solar equipment.

Purpose-built warehousing facilities, equipped with climate control and proper handling equipment, serve as regional hubs across major European markets. These facilities maintain optimal storage conditions for sensitive components like solar panels and inverters while enabling quick response times to installation demands.

Transportation within the solar supply chain involves multiple modes, including sea freight for international shipments, rail transport for cross-continental movement, and specialized trucks for last-mile delivery. Many logistics providers now offer dedicated solar equipment handling services, featuring custom-designed packaging and loading systems to prevent damage during transit.

Advanced tracking systems and real-time monitoring ensure transparency throughout the delivery process. This technology enables precise scheduling of deliveries to installation sites, reducing storage needs and improving project timeline efficiency. Many European distributors maintain local inventory management systems that optimize stock levels based on regional demand patterns.

The emergence of sustainable logistics practices aligns with the industry’s environmental focus. Electric delivery vehicles, optimized routing systems, and eco-friendly packaging solutions are increasingly common in solar equipment distribution. These innovations help reduce the carbon footprint of the supply chain while maintaining the integrity of transported components.

Supply Chain Challenges in Solar Projects

Material Availability and Price Volatility

The solar industry’s reliance on raw materials like silicon, silver, and rare earth elements makes it particularly susceptible to market fluctuations and supply challenges. Recent years have shown how material availability can significantly impact project timelines and costs across Europe. For instance, polysilicon prices have demonstrated considerable volatility, sometimes fluctuating by up to 30% within a single quarter, directly affecting module costs and project budgets.

Supply constraints often emerge from geopolitical tensions, trade policies, and production capacity limitations. These factors can lead to extended lead times for critical components, sometimes stretching from weeks to several months. For European solar projects, this volatility requires careful planning and risk management strategies.

To mitigate these challenges, project developers are increasingly adopting strategic approaches such as maintaining relationships with multiple suppliers, implementing longer-term procurement contracts, and building buffer inventories when possible. Some companies are also exploring alternative materials and technologies to reduce dependence on volatile raw materials.

Price indexing in contracts has become a common practice, helping to share the risk between suppliers and buyers. Additionally, the European Union’s initiatives to strengthen domestic manufacturing capacity and secure supply chains are gradually helping to stabilise material availability and pricing structures for the regional market.

Understanding these market dynamics is crucial for accurate project planning and cost estimation, making it essential to work with experienced partners who can navigate supply chain complexities effectively.

Quality Control and Compliance

Quality control in the solar supply chain is governed by stringent European solar regulations and international standards that ensure product reliability and performance. Key certification requirements include IEC 61215 for module design qualification and IEC 61730 for safety standards. These certifications validate durability, electrical safety, and long-term performance under various environmental conditions.

Manufacturing facilities must maintain ISO 9001 certification, implementing comprehensive quality management systems that track components from raw materials to finished products. Regular factory audits, batch testing, and performance monitoring ensure consistent product quality across the supply chain.

European manufacturers and importers must comply with RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment) directives, promoting environmentally responsible production and end-of-life management. The CE marking is mandatory for solar products sold in the European Economic Area, confirming compliance with health, safety, and environmental protection standards.

Quality assurance processes include:

– Flash testing of every module

– Electroluminescence imaging for defect detection

– Environmental stress testing

– Performance ratio verification

– Documentation and traceability systems

These measures protect consumers and maintain industry standards while supporting the sustainable growth of Europe’s solar energy sector. Regular updates to quality standards ensure continuous improvement and adaptation to technological advances.

Optimizing Your Solar Supply Chain

Strategic Supplier Partnerships

In today’s dynamic solar market, successful project implementation heavily relies on building supplier relationships that are both robust and sustainable. European solar developers understand that establishing strategic partnerships with reliable component manufacturers and distributors is crucial for maintaining consistent project delivery and quality standards.

Key to these partnerships is the development of long-term agreements that ensure priority access to critical components like solar panels, inverters, and mounting systems. Such arrangements often include guaranteed supply volumes, preferential pricing, and dedicated technical support. European suppliers are increasingly offering customized solutions that align with local regulations and specific project requirements.

Quality assurance plays a vital role in these partnerships. Leading European suppliers maintain rigorous testing protocols and certification standards, providing transparency throughout the supply chain. This commitment to quality helps project developers maintain high performance standards while meeting strict European regulatory requirements.

Communication channels between partners should remain open and efficient, with regular updates on production schedules, inventory levels, and potential supply disruptions. Many successful partnerships implement shared digital platforms for real-time tracking and forecasting, enabling better planning and risk management.

To strengthen these relationships, companies often establish joint innovation initiatives, sharing research and development costs while working towards improved product efficiency and sustainability. This collaborative approach has proven particularly effective in addressing the evolving needs of the European solar market, while fostering technological advancement and cost reduction throughout the supply chain.

Inventory Management Systems

Modern inventory management systems play a crucial role in maintaining an efficient solar supply chain across Europe. These sophisticated platforms combine real-time tracking, data analytics, and predictive modeling to ensure optimal stock levels of solar panels, inverters, mounting systems, and other essential components.

Smart warehouse management solutions now integrate IoT sensors and RFID technology to monitor inventory levels automatically. This technology enables precise tracking of components from receipt to dispatch, reducing the risk of stockouts while preventing excess inventory that ties up capital. For solar installers and distributors, these systems provide immediate visibility into available stock and expected delivery times.

Demand forecasting has evolved significantly, incorporating artificial intelligence and machine learning algorithms to analyze historical data, seasonal patterns, and market trends. These tools help businesses anticipate demand fluctuations, particularly important in Europe’s diverse climate zones where installation peaks vary by region.

Just-in-time inventory practices, adapted specifically for solar supply chains, help companies maintain optimal stock levels while reducing warehousing costs. Modern systems can automatically trigger reorder points based on real-time demand, supplier lead times, and project pipelines.

Cloud-based inventory platforms enable seamless collaboration between manufacturers, distributors, and installers. These systems provide real-time updates on component availability, allowing project managers to plan installations more effectively and adjust schedules based on material availability.

For European solar businesses, these advanced inventory management solutions offer particular value in navigating the complexities of cross-border trade, varying national regulations, and seasonal demand fluctuations. They help maintain supply chain resilience while supporting the growing demand for solar energy solutions across the continent.

Digital Integration and Automation

In today’s rapidly evolving solar industry, digital integration and automation have become crucial elements in streamlining supply chain operations. Modern solar supply chains leverage advanced technologies to enhance visibility, improve efficiency, and reduce operational costs. Smart tracking systems, powered by IoT sensors, provide real-time monitoring of component locations, storage conditions, and delivery schedules, ensuring optimal inventory management and reducing delays.

Cloud-based platforms integrate various stakeholders – from manufacturers to installers – creating a seamless communication network that expedites decision-making and problem-solving. These platforms offer comprehensive dashboards that display key performance indicators, inventory levels, and supply chain bottlenecks, enabling proactive management of potential issues.

The implementation of data analytics for supply chain optimization has revolutionized how solar companies predict demand patterns, optimize routing, and manage warehouse operations. Machine learning algorithms analyze historical data to forecast component requirements, helping businesses maintain optimal stock levels while reducing storage costs.

Blockchain technology is emerging as a powerful tool for supply chain transparency, enabling stakeholders to trace components from manufacture to installation. This enhanced traceability ensures quality control, reduces counterfeiting risks, and helps maintain compliance with European sustainability standards.

Automation solutions, such as robotic process automation (RPA), streamline administrative tasks like order processing, supplier communications, and documentation management. These systems reduce human error, accelerate processing times, and allow staff to focus on strategic activities that add more value to the supply chain.

For European solar projects, digital integration particularly benefits cross-border operations, helping navigate complex regulatory requirements and customs procedures. Advanced software systems automatically update compliance documentation and shipping requirements, ensuring smooth movement of components across European markets while maintaining full regulatory adherence.

The optimization of solar supply chains plays a pivotal role in the successful deployment of renewable energy projects across Europe. By effectively managing component sourcing, logistics, and delivery processes, stakeholders can significantly reduce project risks, control costs, and ensure timely completion of solar installations.

As we’ve explored throughout this article, a well-managed supply chain encompasses multiple interconnected elements, from manufacturer relationships and quality control to inventory management and final delivery. The increasing demand for solar solutions in European markets necessitates robust supply chain strategies that can adapt to market fluctuations while maintaining reliability and efficiency.

Success in solar project delivery depends heavily on proactive supply chain management, including diversified supplier networks, strategic inventory planning, and streamlined logistics operations. Companies that invest in supply chain optimization often experience reduced lead times, better cost control, and enhanced project outcomes.

Looking ahead, the evolution of solar supply chains will continue to be shaped by technological innovations, sustainability requirements, and changing market dynamics. European businesses and homeowners can benefit from working with partners who demonstrate strong supply chain expertise and maintain established relationships throughout the solar component ecosystem.

By prioritizing supply chain excellence, stakeholders can better navigate challenges while delivering successful solar installations that contribute to Europe’s renewable energy goals. This comprehensive approach ensures project reliability, cost-effectiveness, and long-term sustainability in the growing solar energy sector.

Leave a Reply