3-Phase Solar Inverters: Powering Industrial Automation with Smart Grid Integration

Transform your industrial power infrastructure with three-phase solar inverters – the cornerstone of modern industrial automation with solar power. These sophisticated power conversion systems synchronize renewable energy with your facility’s three-phase electrical network, delivering optimal performance for heavy machinery and automated processes.

Operating at 400V/50Hz across European industrial standards, three-phase inverters achieve conversion efficiencies exceeding 98%, significantly reducing energy losses in high-power applications. Their integrated power management systems automatically balance loads across phases while maintaining stable voltage levels – essential for sensitive manufacturing equipment and automated production lines.

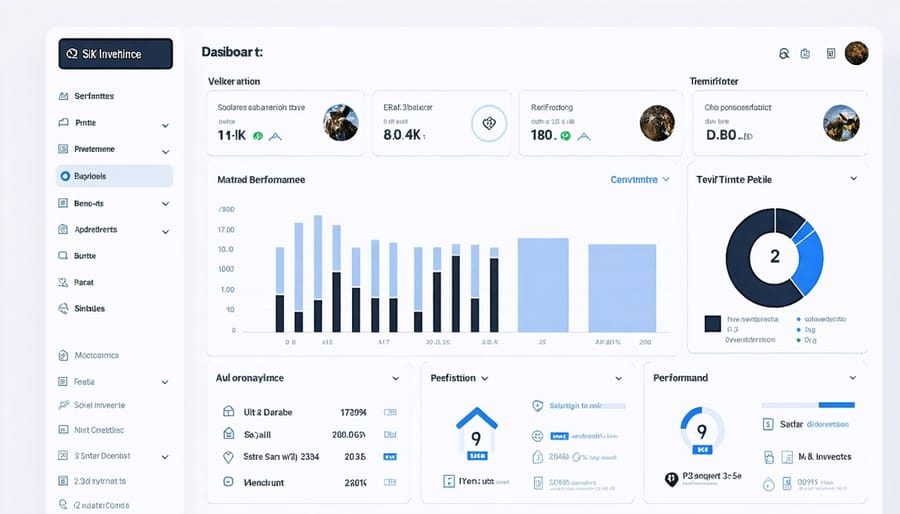

For facility managers and industrial engineers, these inverters represent more than just power conversion – they’re the gateway to sustainable manufacturing, reduced operational costs, and enhanced grid independence. With built-in monitoring capabilities and smart grid compatibility, modern three-phase inverters seamlessly integrate with existing industrial control systems while providing real-time performance analytics and predictive maintenance alerts.

Understanding 3-Phase Solar Inverters in Industrial Settings

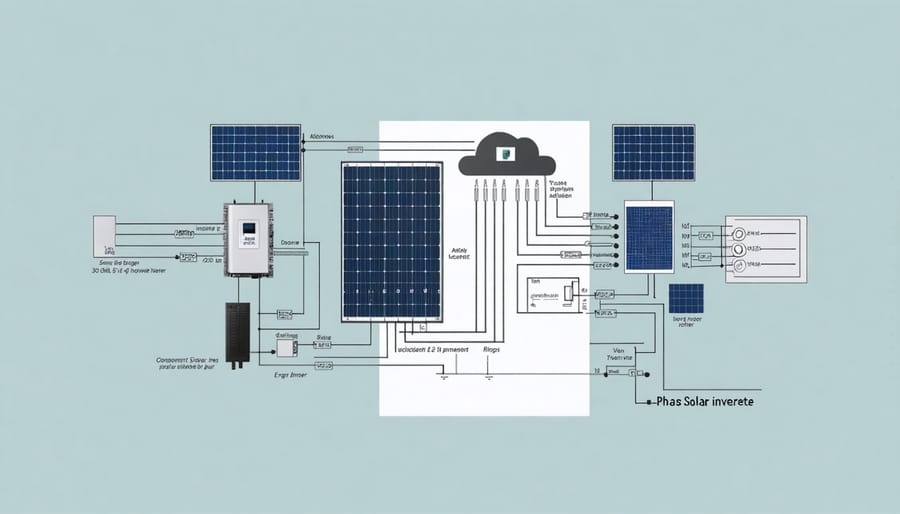

Key Components and Architecture

A 3-phase solar power inverter comprises several essential components working in harmony to convert DC power from solar panels into grid-compatible AC power. At its core, the system features power semiconductor devices, typically IGBTs (Insulated Gate Bipolar Transistors) or MOSFETs, arranged in a three-bridge configuration. These components handle the switching operations necessary for DC to AC conversion.

The control system forms another crucial element, incorporating sophisticated microprocessors and digital signal processors (DSPs) that manage power flow and maintain synchronization with the grid. Advanced filtering components, including LCL filters, ensure the output power meets strict European grid codes and harmonics requirements.

The architecture typically follows a modular design approach, with separate power stages for each phase. This includes DC input protection, power conversion stages, and output filtering circuits. A robust cooling system, either passive or active, maintains optimal operating temperatures for enhanced efficiency and longevity.

Modern 3-phase inverters also integrate smart monitoring systems and communication interfaces, enabling remote management and performance optimization. Protection mechanisms, such as ground fault interrupters and surge protection devices, safeguard the system against electrical anomalies.

The entire assembly is housed in an IP65-rated enclosure, ensuring protection against environmental factors while complying with European safety standards. This sophisticated architecture delivers reliable, efficient power conversion while maintaining grid stability and power quality.

Grid Integration Capabilities

Modern 3-phase solar inverters excel in their grid integration capabilities, offering sophisticated features that ensure seamless interaction with the power grid while maintaining stability and reliability. These inverters incorporate advanced grid monitoring systems that continuously analyse grid parameters, including voltage, frequency, and power quality, adjusting their output accordingly.

A key feature is Low Voltage Ride Through (LVRT), which enables the inverter to remain connected during brief grid disturbances, supporting grid stability rather than disconnecting immediately. This capability is particularly valuable in regions with high renewable energy penetration, helping maintain grid reliability during fluctuations.

Smart grid compatibility is another crucial aspect, with these inverters offering bi-directional communication capabilities. They can respond to grid operator commands, adjust power factor settings, and participate in grid services such as voltage regulation and frequency support. This advanced functionality helps network operators maintain grid stability while maximising renewable energy integration.

For European installations, these inverters comply with strict grid codes such as VDE-AR-N 4105 and EN 50549, ensuring proper operation within the continental power network. Many models feature customisable grid protection settings, allowing for adaptation to specific regional requirements and future grid code updates.

The integration capabilities extend to energy management systems, enabling automated power flow optimization and strategic energy storage coordination, particularly beneficial for commercial and industrial applications.

Industrial Automation Benefits

Enhanced Power Quality Control

Three-phase solar power inverters incorporate advanced power quality control features that are essential for maintaining grid stability and transforming manufacturing processes across Europe. These sophisticated systems employ multiple layers of protection and control mechanisms to ensure optimal power delivery and system reliability.

At the heart of enhanced power quality control is reactive power compensation, which helps maintain voltage stability and power factor correction. Modern three-phase inverters can dynamically adjust their output to compensate for voltage fluctuations, ensuring consistent power delivery even under varying load conditions.

The integration of advanced harmonic filtering technology significantly reduces total harmonic distortion (THD), resulting in cleaner power output that meets strict European grid codes. This is particularly crucial for sensitive industrial equipment and automated systems that require stable, high-quality power supply.

Real-time monitoring and rapid response capabilities enable these inverters to detect and respond to power quality issues within milliseconds. Features such as anti-islanding protection, voltage ride-through capability, and frequency regulation contribute to a more resilient grid connection.

The implementation of sophisticated algorithms allows for:

– Precise voltage regulation within ±1% of nominal value

– Active power curtailment when required

– Seamless grid synchronization

– Automatic fault detection and recovery

These enhanced power quality control features not only ensure compliance with European grid standards but also contribute to longer equipment life spans and reduced maintenance requirements. For industrial applications, this translates to improved operational reliability and reduced downtime, making three-phase solar inverters an integral component of sustainable energy infrastructure.

Energy Management and Cost Reduction

Three-phase solar power inverters play a crucial role in reducing operational costs and enhancing energy efficiency for industrial and commercial installations. Through advanced power conversion technology, these systems optimize solar energy utilization while minimizing energy losses during the conversion process. Recent studies show that properly configured three-phase inverters can achieve conversion efficiencies of up to 98.5%, significantly reducing energy waste and operating expenses.

The implementation of smart monitoring and control features in modern three-phase inverters enables precise energy optimization in industry, allowing businesses to maximize their return on investment. These systems automatically adjust power output based on demand patterns, grid conditions, and available solar resources, ensuring optimal energy distribution throughout the facility.

Cost reduction benefits extend beyond mere energy savings. Three-phase inverters reduce maintenance requirements through sophisticated self-diagnostic capabilities and remote monitoring features. This predictive maintenance approach helps prevent unexpected downtime and extends system longevity, resulting in lower long-term operational costs.

For European businesses, the integration of three-phase solar inverters often qualifies for various renewable energy incentives and tax benefits, further enhancing the financial advantages. When combined with time-of-use tariffs and demand response programs, these systems can significantly reduce peak demand charges and optimize energy consumption patterns, leading to substantial savings on utility bills.

Moreover, the scalability of three-phase inverter systems allows businesses to expand their solar capacity gradually, managing initial investment costs while maintaining the flexibility to grow with increasing energy demands.

Implementation Considerations

System Sizing and Specifications

Selecting the right size and specifications for a 3-phase solar inverter requires careful consideration of several key factors. For optimal performance in industrial solar solutions, system sizing should align with both current needs and future expansion plans.

First, calculate the total power requirements of your facility by analyzing peak demand periods and average daily consumption. The inverter’s capacity should be 10-20% higher than your solar array’s DC rating to account for varying solar conditions and system inefficiencies.

Key specifications to consider include:

– Nominal AC output voltage (typically 400V in Europe)

– Maximum DC input voltage (usually 1000V or 1500V)

– Maximum Power Point Tracking (MPPT) range

– European efficiency rating (minimum 97%)

– Grid connection requirements

– Protection class (minimum IP65 for outdoor installation)

For European installations, ensure compliance with VDE-AR-N 4105 and EN 50549-1/-2 standards. The inverter must feature anti-islanding protection and power quality monitoring capabilities to meet local grid requirements.

Consider environmental factors such as installation location, ambient temperature range, and altitude, as these can affect inverter performance. Modern 3-phase inverters typically operate efficiently between -25°C and +60°C.

For maximum reliability, select inverters with monitoring capabilities and smart grid features. This enables remote diagnostics and ensures compliance with evolving grid regulations while optimizing energy production and distribution.

Installation and Safety Standards

The installation of three-phase solar inverters in Europe must comply with stringent safety standards and regulations to ensure optimal performance and protection. The primary framework governing these installations is the European Low Voltage Directive (LVD) 2014/35/EU, which sets comprehensive safety requirements for electrical equipment operating between 50 and 1000V AC.

Installers must adhere to IEC 62109-1 and IEC 62109-2 standards, specifically designed for power converters in photovoltaic systems. These standards outline crucial safety features, including ground fault protection, isolation monitoring, and electromagnetic compatibility requirements.

The installation process requires professional certification and must follow local grid codes. Key safety measures include proper IP-rated enclosures (minimum IP65 for outdoor installations), adequate ventilation systems, and appropriate surge protection devices. The inverter must be equipped with automatic disconnection capabilities and monitoring systems that comply with EN 50549-1:2019 for grid connection requirements.

Maintenance access points must remain unobstructed, with clear safety signage and emergency shutdown procedures visibly displayed. The installation area should maintain minimum clearance distances as specified by manufacturers, typically 500mm on all sides for adequate cooling and servicing.

Documentation requirements include detailed electrical schemas, maintenance schedules, and emergency response procedures. Regular safety inspections are mandatory, with intervals determined by local regulations and insurance requirements. System integrators must ensure compatibility with existing electrical infrastructure and implement proper grounding systems according to HD 60364-7-712 standards.

For maximum safety and compliance, it’s recommended to work with certified installers who understand both local and EU-wide regulations, ensuring a professional installation that meets all current safety standards while maintaining optimal system performance.

Maintenance and Monitoring

Regular maintenance and diligent monitoring are crucial for ensuring optimal performance and longevity of your 3-phase solar inverter system. Schedule quarterly visual inspections to check for physical damage, loose connections, and signs of wear. Pay special attention to ventilation systems and heat sinks, keeping them free from dust and debris to maintain efficient cooling.

Monitor your system’s performance through the integrated monitoring platform, which provides real-time data on power output, conversion efficiency, and system health. Many modern inverters offer remote monitoring capabilities via smartphone apps or web portals, allowing you to track performance metrics and receive instant alerts about potential issues.

Keep detailed maintenance logs and performance records, which are essential for warranty claims and system optimization. Check error codes promptly and consult your manual or professional technician when unusual patterns emerge. In European climates, seasonal maintenance is particularly important – inspect for weather-related damage after storms and ensure optimal performance during peak production months.

Professional maintenance checks are recommended annually, including thermal imaging to detect hotspots, electrical testing of components, and firmware updates. This proactive approach helps prevent system failures and maintains the high efficiency levels expected from 3-phase inverters. Remember to verify that maintenance personnel are certified for working with high-voltage systems and familiar with local regulations.

Three-phase solar inverters have proven to be instrumental in advancing industrial automation and sustainable energy solutions across Europe. Their superior efficiency, enhanced grid stability, and robust power management capabilities make them an invaluable asset for businesses transitioning towards renewable energy. The ability to handle higher power outputs while maintaining exceptional performance has positioned these inverters as a cornerstone of modern industrial solar installations.

Looking ahead, the future of three-phase solar inverters appears particularly promising. Technological advancements continue to drive improvements in efficiency ratings, now regularly exceeding 98%. Integration with smart grid systems and Industry 4.0 technologies is becoming increasingly sophisticated, offering enhanced monitoring capabilities and predictive maintenance features that reduce operational costs and downtime.

The European Union’s commitment to carbon neutrality by 2050 further strengthens the case for widespread adoption of three-phase solar inverters. As industrial automation becomes more energy-intensive, these systems offer a sustainable solution that aligns with both environmental goals and operational requirements. Emerging trends suggest future inverters will feature enhanced energy storage integration, advanced grid support functions, and improved cybersecurity measures.

For industries considering the transition to solar power, three-phase inverters represent a future-proof investment that delivers immediate benefits while preparing for tomorrow’s energy landscape. Their role in industrial automation will continue to expand, driven by ongoing innovations in power electronics and digital integration capabilities.

Leave a Reply