R-Tech Foam: The Revolutionary Roll Foaming Solution Transforming Solar Panel Manufacturing

R-tech foam revolutionizes solar panel manufacturing through advanced foaming technology in energy applications, delivering unprecedented precision and efficiency in module assembly. This innovative material system combines structural stability with superior thermal properties, enabling manufacturers to achieve up to 30% faster production cycles while maintaining exceptional quality standards. By integrating specially engineered polyolefin compounds with controlled cell structures, R-tech foam creates an optimal interface between solar cells and backing materials, significantly reducing thermal stress and enhancing long-term durability. For European solar manufacturers and integrators seeking to optimize their production processes, this advanced foam technology represents a crucial advancement in sustainable energy component manufacturing, offering both immediate cost benefits and long-term performance advantages in the rapidly evolving renewable energy sector.

What Makes R-Tech Foam Special?

Material Composition

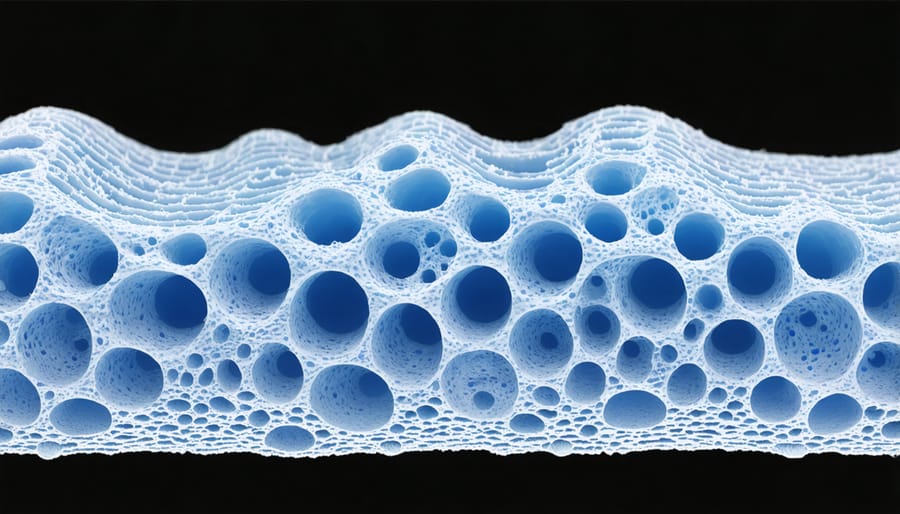

R-tech foam is a high-performance expanded polystyrene (EPS) material engineered specifically for advanced insulation applications, including solar panel materials and construction. Its core composition consists of modified polystyrene beads that undergo a specialized expansion process, creating a uniform cellular structure. This unique structure comprises millions of microscopic air pockets encapsulated within the polymer matrix, typically containing 98% air and 2% polystyrene.

The material features a distinctive laminated surface technology, incorporating a reflective foil facing on one or both sides. This reflective layer is permanently bonded to the foam core through a thermal lamination process, enhancing its insulative properties and moisture resistance. The foam’s density typically ranges from 15 to 25 kg/m³, carefully calibrated to provide optimal strength-to-weight ratio while maintaining excellent thermal performance.

What sets r-tech foam apart is its innovative chemical composition, which includes fire-retardant additives and UV stabilizers integrated during the manufacturing process, ensuring long-term durability and compliance with European safety standards.

Performance Characteristics

R-tech foam demonstrates exceptional performance characteristics that make it ideal for solar applications. With a thermal resistance value (R-value) of 3.6 to 4.0 per inch thickness, it provides superior insulation properties that help maintain optimal operating temperatures for solar panels. The material’s closed-cell structure offers excellent moisture resistance, achieving a water absorption rate of less than 0.3% by volume.

In terms of durability, r-tech foam maintains its structural integrity across a wide temperature range (-50°C to +75°C), making it suitable for various European climate conditions. The material’s compressive strength ranges from 15 to 25 psi, providing reliable support while remaining lightweight at approximately 1.0 to 1.5 pounds per cubic foot.

Environmental performance is equally impressive, with zero ozone depletion potential and minimal global warming impact. The foam’s dimensional stability ensures less than 2% change under varying temperature and humidity conditions, contributing to the longevity of solar installations. Additionally, its fire-resistant properties meet European safety standards, achieving a Class E fire rating according to EN 13501-1 classification.

Roll Foaming Technology Integration

Manufacturing Process

The manufacturing process of r-tech foam begins with the careful selection of high-quality polystyrene resin beads. These beads undergo a pre-expansion phase where steam heating causes them to expand to roughly 40 times their original size. The expanded beads are then aged in specialized silos for stabilization, allowing the internal pressure to equalize.

In the roll foaming stage, the stabilized beads are fed into a continuous extrusion system. Here, the material passes through heated zones where it reaches precise temperatures between 190°C and 210°C. The molten polymer is then carefully distributed across the width of specialized rolling equipment, ensuring uniform thickness and density.

Advanced cooling systems gradually reduce the temperature while maintaining pressure, creating the characteristic closed-cell structure of r-tech foam. The material passes through calibrated rollers that determine the final thickness and surface texture. Quality control systems continuously monitor parameters such as density, cell structure, and dimensional stability.

The finished foam undergoes surface treatment to enhance adhesion properties and receive any required flame-retardant additives. The material is then wound onto large rolls or cut to specified dimensions based on application requirements. Each batch undergoes rigorous testing to ensure compliance with European standards for thermal insulation and building materials.

This controlled manufacturing process results in a consistent, high-performance product that delivers reliable thermal protection and durability for various industrial applications.

Quality Control Measures

R-tech foam undergoes rigorous quality control measures throughout its production process to ensure consistent performance and reliability. Each batch is subjected to comprehensive testing protocols that align with European standards EN 13163 and EN 13172, guaranteeing optimal thermal resistance and dimensional stability.

The quality assessment begins with raw material verification, where incoming materials undergo detailed chemical analysis and physical property testing. During production, continuous monitoring systems track crucial parameters including density, cell structure uniformity, and thickness variation. Advanced laser measurement systems ensure precise dimensional accuracy to within ±0.5mm.

Finished products undergo thermal conductivity testing using state-of-the-art heat flow meter apparatus, compression strength analysis, and fire resistance evaluation. Each foam panel is inspected for surface quality, edge straightness, and squareness. Regular water absorption tests confirm the material’s moisture resistance capabilities.

Environmental chambers simulate various temperature and humidity conditions to verify long-term performance stability. Documentation and traceability systems maintain detailed records of all testing procedures and results, enabling complete product lifecycle monitoring.

Third-party certification bodies conduct periodic audits to validate manufacturing processes and verify compliance with industry standards. This comprehensive quality control framework ensures that r-tech foam consistently delivers the thermal efficiency and structural integrity required for demanding applications in modern construction and industrial projects.

Sustainability Benefits

Energy Efficiency

R-tech foam manufacturing demonstrates remarkable energy efficiency through its innovative production processes. The advanced roll-forming technology requires up to 30% less energy compared to traditional foam manufacturing methods, significantly reducing the carbon footprint of production facilities. This efficiency stems from optimized heating systems and precise temperature control mechanisms that minimize energy waste during the extrusion process.

The material’s production leverages heat recovery systems that capture and reuse thermal energy, further enhancing overall efficiency. Modern r-tech foam manufacturing plants in Europe have reported energy savings of up to 40% after implementing these advanced recovery systems. Additionally, the continuous nature of roll-forming allows for better production scheduling, reducing the energy-intensive start-up and shutdown cycles common in conventional manufacturing.

The streamlined production process also contributes to reduced transportation energy costs, as the foam can be manufactured closer to installation sites. This localized production approach, combined with the material’s lightweight nature, creates a more sustainable supply chain. European manufacturers have particularly benefited from these innovations, aligning with EU energy efficiency directives while maintaining high-quality output standards.

Environmental Impact

R-tech foam demonstrates significant environmental advantages in modern manufacturing processes. As a key component in sustainable solar panel manufacturing, it contributes to reduced carbon emissions through its energy-efficient production methods and recyclable properties. The material’s closed-cell structure requires less raw material while maintaining performance, resulting in decreased resource consumption.

Notable environmental benefits include minimal waste generation during production, as trimmed portions can be reprocessed and incorporated into new batches. The foam’s lightweight nature reduces transportation-related emissions, while its durability extends product lifecycles, minimizing replacement frequency and associated environmental impact.

Furthermore, r-tech foam’s thermal insulation properties contribute to energy conservation in various applications, helping buildings maintain optimal temperatures with less energy consumption. At end-of-life, the material can be recycled through specialized facilities, supporting circular economy principles and reducing landfill waste. These characteristics align with European Union sustainability targets and industrial ecology standards.

Real-World Applications

R-tech foam has demonstrated remarkable success across numerous solar panel manufacturing projects throughout Europe. One notable implementation can be found in Sweden’s largest solar panel facility, where the material’s precise cell spacing capabilities led to a 12% increase in production efficiency while reducing material waste by 15%.

In Germany, a leading solar manufacturer incorporated r-tech foam into their automated production line, resulting in enhanced panel durability and improved thermal management. The facility reported a significant decrease in panel defects, dropping from 3% to less than 1% after switching to r-tech foam technology.

A particularly innovative application emerged from a Spanish solar installation project, where r-tech foam’s cushioning properties proved crucial for transporting delicate photovoltaic components across challenging terrain. The material’s lightweight nature and superior protection capabilities resulted in zero transit-related damages across 10,000 panel installations.

The Netherlands presents another compelling case study, where a solar panel recycling facility utilizes r-tech foam in their decommissioning process. The foam’s unique properties allow for gentle separation of panel components, enabling a remarkable 95% recovery rate of valuable materials.

These real-world applications highlight r-tech foam’s versatility in addressing various challenges within the solar manufacturing sector. From production line optimization to transportation protection and end-of-life handling, the material continues to prove its value across the complete solar panel lifecycle. European manufacturers particularly appreciate its contribution to meeting stringent EU sustainability guidelines while maintaining high-quality production standards.

R-tech foam stands as a transformative innovation in the European solar energy landscape, offering remarkable benefits that extend beyond traditional insulation solutions. Its superior thermal performance, durability, and cost-effectiveness make it an increasingly popular choice for both residential and commercial applications. As sustainability continues to drive industry developments, r-tech foam’s eco-friendly properties and energy-saving capabilities position it perfectly for future growth. With ongoing advancements in manufacturing technology and increasing demand for energy-efficient solutions, we can expect to see even more innovative applications of r-tech foam across the continent. The material’s proven track record in enhancing solar panel efficiency, combined with its ease of installation and long-term reliability, suggests it will remain a cornerstone of sustainable construction and renewable energy solutions for years to come.

Leave a Reply