Thin-Film Solar: The Breakthrough Making European Solar More Accessible

Thin-film solar technology represents one of the most promising innovations in renewable energy, offering unprecedented flexibility and integration possibilities for European buildings and infrastructure. Unlike traditional solar panels, these ultra-thin photovoltaic layers can be as slim as a few micrometers, revolutionizing how we harness solar power in urban environments.

As Europe accelerates its transition to sustainable energy, thin-film solar panels emerge as a game-changing solution, particularly for spaces where conventional panels prove impractical. Their lightweight nature and ability to conform to curved surfaces open new possibilities for solar integration in everything from historic buildings to modern architectural designs.

Recent technological breakthroughs have pushed thin-film efficiency rates above 23% in laboratory conditions, while manufacturing costs continue to decrease. This convergence of improved performance and economic viability marks a crucial turning point for the technology’s widespread adoption across European markets.

For architects, developers, and property owners seeking sustainable energy solutions, thin-film solar technology offers a compelling blend of aesthetics, functionality, and environmental responsibility. As we move towards carbon-neutral buildings and smart cities, these innovative panels are becoming an increasingly vital component of Europe’s renewable energy landscape.

The Evolution of Thin-Film Solar Technology

Key Materials and Manufacturing Processes

The manufacturing of thin-film solar panels involves several sophisticated processes and key materials used in solar panels. The most common materials include amorphous silicon (a-Si), cadmium telluride (CdTe), and copper indium gallium selenide (CIGS). Each material offers unique advantages in terms of efficiency and production costs.

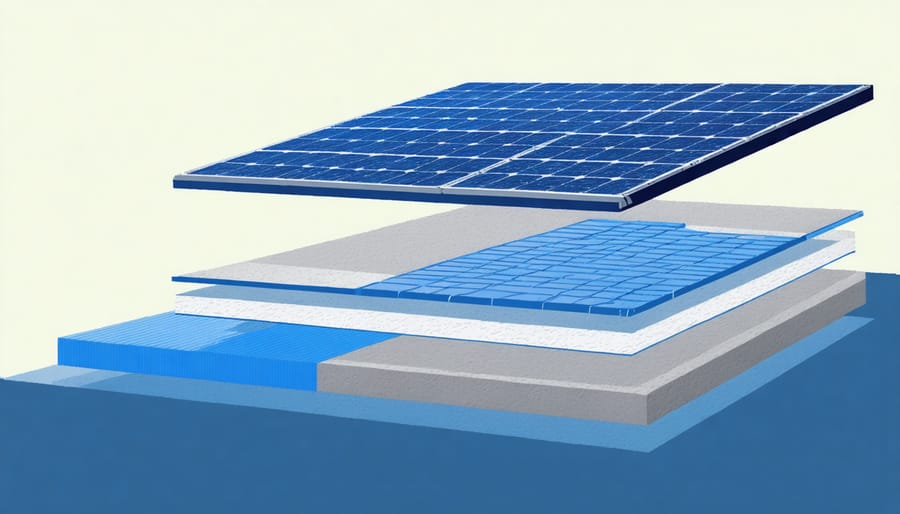

The manufacturing process begins with depositing these semiconducting materials in extremely thin layers—typically just a few micrometers thick—onto flexible or rigid substrates like glass, metal, or plastic. This deposition occurs in a vacuum chamber using techniques such as sputtering or vapor deposition. The process requires precise control of temperature and pressure to ensure uniform layer formation.

A transparent conducting oxide (TCO) layer is then applied as the front electrical contact, followed by the photovoltaic material layers. The final steps include adding a back contact layer and encapsulation to protect the cells from environmental factors. This entire process is highly automated and can be completed in a continuous roll-to-roll manufacturing system, making it more cost-effective than traditional solar panel production methods.

Advantages Over Traditional Solar Panels

Thin-film solar panels offer several distinct advantages over their traditional counterparts, making them an increasingly attractive option for diverse applications. Their exceptional flexibility allows installation on curved surfaces and irregular structures, opening up new possibilities for architectural integration. This adaptability is particularly valuable in Europe’s diverse urban landscapes, where conventional rigid panels might not be suitable.

The significantly lower weight of thin-film panels – often up to 90% lighter than traditional modules – reduces structural requirements and installation costs. This characteristic makes them ideal for buildings with limited load-bearing capacity, such as older structures common across European cities.

Installation is notably more straightforward, requiring less robust mounting systems and reducing overall labour costs. The panels’ ability to perform efficiently in low-light conditions and high temperatures gives them an edge in varied European climates. They maintain better performance during cloudy days and can operate effectively even when partially shaded.

These panels also demonstrate superior sustainability credentials, requiring less energy and raw materials in their production process, aligning with Europe’s ambitious environmental goals and circular economy initiatives.

Latest Innovations in Thin-Film Technology

Enhanced Efficiency Technologies

Recent efficiency breakthroughs in solar technology have significantly enhanced thin-film solar panel performance. Advanced light-trapping techniques, incorporating nano-textured surfaces and innovative anti-reflective coatings, now enable panels to capture a broader spectrum of solar radiation. These improvements have pushed conversion efficiencies beyond 20% in laboratory settings.

Multi-junction cell architecture represents another major advancement, allowing thin-film panels to absorb different wavelengths of light through multiple semiconductor layers. This technology has proven particularly effective in CIGS (Copper Indium Gallium Selenide) cells, where researchers have achieved remarkable stability and performance gains.

European laboratories have pioneered the development of transparent conducting oxides (TCOs) that enhance electrical conductivity while maintaining optimal light transmission. These materials, combined with improved manufacturing processes, have reduced production costs while increasing panel durability.

The integration of smart monitoring systems and self-cleaning surfaces has further optimized real-world performance. Advanced encapsulation techniques protect the sensitive semiconductor layers from environmental factors, extending panel lifespan and maintaining efficiency over time.

Emerging technologies like perovskite-based thin films show exceptional promise, with rapid efficiency improvements and the potential for low-cost mass production. These innovations are particularly relevant for building-integrated photovoltaics (BIPV), where aesthetics and flexibility are as important as performance.

Integration Capabilities

One of the most compelling advantages of thin-film solar technology is its remarkable integration flexibility. Thanks to their lightweight and flexible nature, these panels can be seamlessly incorporated into various building elements and vehicles in ways traditional solar panels cannot achieve.

In building-integrated photovoltaics (BIPV), thin-film panels can be applied directly to windows, facades, and roofing materials. This integration creates what architects call “active building elements,” where the solar technology becomes part of the structure itself rather than an addition to it. For instance, thin-film panels can be laminated between glass panels to create semi-transparent solar windows or integrated into curved roof tiles without compromising their aesthetic appeal.

The automotive sector has also embraced thin-film technology, with manufacturers incorporating these panels into vehicle roofs and bodies. The panels’ flexibility allows them to follow the natural contours of vehicles while contributing to onboard power generation. This is particularly valuable for electric vehicles, where the additional power can extend driving range.

In urban environments, thin-film panels can be integrated into street furniture, bus shelters, and sound barriers along motorways. Their ability to perform well in diffuse light and partial shade makes them especially suitable for vertical installations on building facades, where traditional panels might be less effective.

Recent European projects have demonstrated innovative applications, including solar-powered advertising displays and protective canopies that generate clean energy while providing shelter from the elements.

Practical Applications in European Markets

Residential Applications

Thin-film solar panels are increasingly finding their way into residential applications across Europe, offering homeowners innovative solutions for sustainable energy generation. These panels excel in situations where traditional solar installations might not be feasible, such as on curved surfaces or lightweight roofs that cannot support heavier panels.

Modern thin-film installations can be seamlessly integrated into existing roof tiles or building materials, preserving the aesthetic appeal of homes while generating clean energy. This architectural flexibility makes them particularly attractive for heritage properties and design-conscious homeowners. In regions with diffuse light conditions, such as Northern Europe, thin-film panels maintain relatively consistent energy production even during overcast days.

Homeowners are also discovering the advantages of thin-film technology for vertical installations on facades and windows, transforming previously unused surfaces into power-generating assets. The panels’ performance in partial shade conditions makes them ideal for urban settings where neighbouring buildings or trees might cast shadows.

Recent innovations have improved the efficiency of residential thin-film installations, with some systems now achieving conversion rates that make them competitive with traditional panels, especially when considering the total surface area available for installation.

Commercial and Industrial Uses

Thin-film solar panels have established themselves as a compelling solution for commercial and industrial applications across Europe. Their lightweight nature and flexibility make them particularly suitable for large-scale rooftop installations on factories, warehouses, and commercial buildings where traditional panels might exceed structural load limits.

In industrial settings, thin-film technology offers unique advantages for integration into building materials. Companies can incorporate these panels into facades, windows, and curved surfaces, transforming otherwise unused spaces into power-generating assets. This building-integrated approach has gained significant traction in sustainable architecture projects throughout European urban centres.

The technology proves especially valuable in regions with diffuse light conditions or where panels cannot be optimally oriented. Manufacturing facilities in Northern Europe, for instance, benefit from thin-film’s superior performance in low-light conditions and higher energy yield at oblique angles.

Large retail chains and logistics centres increasingly adopt thin-film solutions for their sustainability initiatives. These installations typically require less maintenance than conventional systems and maintain efficiency even when partially shaded by nearby structures or equipment. The reduced installation time and lower structural requirements also translate into cost savings for large-scale commercial projects, making them an economically sound choice for businesses pursuing renewable energy solutions.

Future Prospects and Market Outlook

Emerging Technologies

The landscape of emerging solar technologies continues to evolve rapidly, with several breakthrough innovations reshaping thin-film solar capabilities. Perovskite solar cells represent one of the most promising developments, offering potential efficiency rates above 25% while maintaining the cost advantages of thin-film technology. European researchers are pioneering tandem cell configurations that combine perovskite with traditional thin-film materials, pushing the boundaries of solar energy conversion.

Quantum dot technology is another revolutionary advancement, enabling better light absorption across the solar spectrum. These microscopic semiconductor particles can be tuned to capture specific wavelengths of light, potentially increasing panel efficiency while reducing production costs. Additionally, transparent thin-film solar cells are being developed for building-integrated photovoltaics, allowing windows and glass surfaces to generate electricity without compromising visibility.

Smart manufacturing techniques, including roll-to-roll printing and advanced coating methods, are streamlining production processes, making thin-film solar panels more accessible and economically viable for diverse applications across Europe’s varied climate zones.

Market Growth Projections

The European thin-film solar panel market is poised for remarkable growth, with projections indicating a compound annual growth rate of 12.8% between 2024 and 2030. This surge is primarily driven by the EU’s ambitious renewable energy targets and increasing demand for sustainable building solutions.

Several key factors are accelerating market expansion across Europe. Germany leads the charge with substantial investments in solar technology research and manufacturing capabilities, while countries like France and Spain are rapidly developing their solar infrastructure. The implementation of innovative building regulations requiring solar installations in new constructions across various EU member states is expected to boost thin-film adoption significantly.

Industry analysts forecast that by 2025, thin-film technology will capture approximately 20% of Europe’s total solar panel market share, up from its current 15%. This growth is supported by improving efficiency rates and decreasing production costs. The commercial and industrial sectors are expected to be the primary growth drivers, particularly in applications where traditional solar panels face limitations.

Major European manufacturers are scaling up production capacity to meet this rising demand, with new facilities planned in several countries. This local manufacturing expansion is expected to reduce dependency on imports and strengthen the European solar industry’s position globally.

Thin-film solar technology represents a significant leap forward in the evolution of renewable energy solutions, offering unique advantages that complement traditional solar installations. With their versatility, reduced material usage, and adaptability to various surfaces, thin-film panels are increasingly becoming an attractive option for European businesses and homeowners alike. The technology’s ability to perform well in diffuse light conditions makes it particularly suitable for Northern European climates, while its aesthetic appeal and flexibility open new possibilities for building integration.

As manufacturing processes continue to improve and efficiency rates climb, thin-film solar panels are poised to play a crucial role in Europe’s renewable energy transition. The technology’s reduced carbon footprint during production, combined with its potential for innovative applications, aligns perfectly with the EU’s sustainability goals. While challenges remain in terms of efficiency compared to traditional panels, ongoing research and development efforts suggest a promising future.

The continued advancement of thin-film technology, coupled with decreasing production costs, positions these solar solutions as a key contributor to a more sustainable and energy-independent Europe. As we move forward, thin-film solar panels will undoubtedly become an increasingly important tool in our renewable energy arsenal.

Leave a Reply