Solar-Powered Desalination: Making Industrial Water Treatment Sustainable

In the face of growing water scarcity, solar solutions for industrial applications are revolutionizing desalination technology across Europe. Solar-powered desalination units harness renewable energy to transform seawater into clean, potable water while significantly reducing operational costs and environmental impact. These innovative systems combine advanced photovoltaic technology with reverse osmosis processes, achieving water production rates of up to 50,000 liters per day in optimal conditions. For industries and municipalities along Europe’s coastlines, this breakthrough represents a sustainable answer to water security challenges, offering energy independence and reduced carbon emissions. The integration of smart monitoring systems and automated operation protocols ensures consistent performance while minimizing maintenance requirements, making these units increasingly attractive for both industrial and community-scale applications. As water stress intensifies across the continent, solar-powered desalination emerges as a crucial tool in building resilient water infrastructure for future generations.

How Solar-Powered Desalination Transforms Industrial Water Treatment

Key Components of Solar Desalination Units

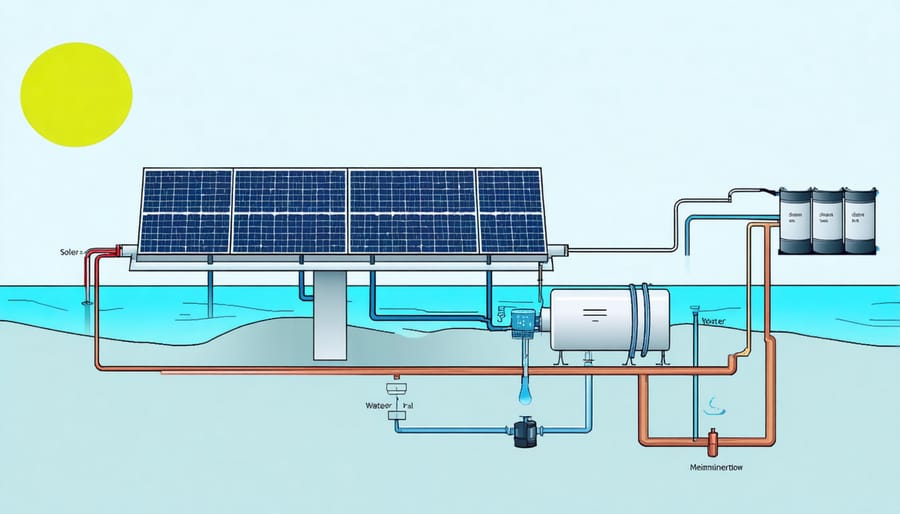

A solar-powered desalination unit comprises several essential components working in harmony to convert seawater into fresh water using solar energy. At the heart of the system lies the solar collector array, typically consisting of photovoltaic panels or solar thermal collectors, which capture and convert sunlight into usable energy.

The intake system, designed with specialized filters, draws seawater while preventing larger debris and marine organisms from entering. This water then passes through the pre-treatment unit, where additional filtration removes smaller particles and adjusts the water chemistry to protect downstream components from scaling and fouling.

The core desalination component varies based on the technology employed. Many modern units utilize reverse osmosis membranes, which require high-pressure pumps powered by solar energy to force seawater through semi-permeable membranes. Alternative systems might employ thermal distillation, where solar heat causes water to evaporate, leaving salt behind.

Energy recovery devices play a crucial role in maintaining efficiency by capturing and recycling pressure energy from the concentrated brine stream. The control system, equipped with sensors and automation technology, monitors and adjusts operating parameters to optimize performance based on available solar energy and water demand.

Post-treatment systems ensure the produced water meets quality standards by adjusting mineral content and pH levels. Finally, the brine management system handles the concentrated saltwater byproduct, implementing environmentally responsible disposal methods or recovery processes.

Storage solutions, including both energy storage systems and freshwater tanks, enable continuous operation during periods of limited sunlight, ensuring reliable water production throughout the day.

Energy Efficiency and Cost Benefits

Solar-powered desalination units represent a significant advancement in cost-effective water treatment solutions, particularly when integrated with industrial solar thermal systems. These innovative systems can reduce operational costs by 40-60% compared to conventional desalination methods, primarily through the elimination of fossil fuel dependency and reduced electricity consumption.

The energy efficiency of solar desalination units is particularly noteworthy, with modern systems achieving thermal efficiency rates of up to 80%. This translates to substantial cost savings, as the primary energy source—solar radiation—is free and abundant. A typical medium-scale solar desalination unit can process 1,000 litres of water daily while consuming only 2-3 kWh of auxiliary electrical energy, compared to 7-12 kWh for traditional reverse osmosis systems.

Investment recovery periods for solar desalination units typically range from 4 to 7 years, depending on installation scale and local solar conditions. European businesses implementing these systems report annual energy cost reductions of €15,000 to €40,000 for medium-sized installations. Additionally, maintenance costs are generally 30% lower than conventional systems due to fewer moving parts and reduced chemical requirements.

The long-term economic benefits extend beyond direct operational savings. With an average lifespan of 20-25 years and minimal degradation in performance, solar desalination units offer predictable operating costs and protection against rising energy prices. Furthermore, many European countries offer incentives and subsidies for renewable energy installations, potentially reducing initial investment costs by 20-40%.

Industrial Applications and Success Stories

Mining Industry Water Treatment

Mining operations require substantial amounts of water for mineral processing, dust suppression, and various other activities. Solar-powered desalination units have emerged as a game-changing solution for the mining sector, particularly in water-scarce regions across Europe. These innovative systems complement existing solar-powered mining operations, creating a sustainable approach to resource extraction.

The integration of solar desalination technology in mining processes offers multiple advantages. It enables mines to treat and reuse process water, reducing their dependence on freshwater sources and minimizing environmental impact. This is particularly crucial in regions where water availability is limited or where strict environmental regulations govern water usage.

The technology proves especially valuable for treating mine drainage and managing acid mine water, converting it into usable water for operational purposes. By implementing solar-powered desalination units, mining companies can achieve significant cost savings on water procurement while demonstrating environmental stewardship.

Modern installations feature advanced monitoring systems that optimize energy usage and water production based on operational demands. This smart integration ensures efficient resource utilization while maintaining consistent water quality standards required for different mining processes. The systems’ modular design allows for scalability, enabling mining operations to adjust their water treatment capacity according to seasonal variations and production requirements.

Manufacturing Process Water

Solar-powered desalination units are increasingly transforming manufacturing processes across Europe, particularly in water-intensive industries. Manufacturing facilities implementing these systems report significant improvements in both water quality and operational sustainability. Recent case studies from industrial parks in Southern Europe demonstrate reduction in process water costs by up to 60% while maintaining consistent quality standards.

The integration of solar-powered desalination units has proven particularly effective in textile manufacturing, food processing, and chemical production facilities. These units typically process between 1,000 and 10,000 litres of water daily, depending on the installation size and available solar exposure. The treated water meets stringent European industrial standards, with total dissolved solids (TDS) levels consistently below 500 parts per million.

Energy consumption data from implemented systems shows that manufacturing facilities can offset approximately 70% of their traditional water treatment energy costs through solar power integration. The modular nature of these units allows for scalable implementation, enabling facilities to expand their treatment capacity as production demands increase. Additionally, the systems’ smart monitoring capabilities ensure optimal performance through real-time adjustment of desalination parameters based on water quality requirements and available solar energy.

Implementation and Integration Guidelines

System Sizing and Requirements

Determining the appropriate size for a solar-powered desalination unit requires careful consideration of several key factors. First, assess your daily freshwater requirements, accounting for seasonal variations and potential future demand increases. For residential applications, calculate approximately 150-200 litres per person per day, while industrial needs vary significantly based on specific processes.

The solar component sizing depends on your geographical location within Europe, with southern regions typically requiring 2-3 kWh of energy per cubic metre of freshwater produced. Consider local solar irradiance data and available installation space when planning your system. For optimal efficiency, factor in about 8-10 square metres of solar panel area per cubic metre of daily water production.

Infrastructure requirements include sufficient land area for both solar panels and desalination equipment, robust foundation support, and appropriate drainage systems. Essential components comprise storage tanks for both feedwater and processed water, pre-treatment facilities, and brine disposal mechanisms that comply with local environmental regulations.

For enhanced system reliability, incorporate buffer storage capacity for both energy and water to maintain operation during lower solar availability periods. Modern monitoring systems and smart controllers help optimise performance and ensure consistent output throughout varying weather conditions. Consider implementing a hybrid system with grid connection as backup for critical applications.

Work with qualified engineers to conduct a detailed site assessment and system sizing calculation, ensuring compliance with regional building codes and environmental standards.

Integration with Existing Systems

Integrating a solar-powered desalination unit into existing water treatment infrastructure requires careful planning and systematic implementation. The process typically begins with a comprehensive site assessment to evaluate current water systems, available space for solar panels, and energy consumption patterns. This evaluation helps determine the optimal configuration for seamless integration.

For industrial facilities, the integration process often involves installing parallel systems initially, allowing for gradual transition without disrupting ongoing operations. Key connection points include the water intake system, pre-treatment facilities, and existing distribution networks. Modern solar desalination units come with standardised interfaces that facilitate compatibility with conventional water treatment equipment.

To ensure successful integration, facilities should implement a smart monitoring system that coordinates between traditional and solar-powered components. This includes automated switches that can alternate between power sources based on solar availability and demand patterns. Additionally, storage solutions for both treated water and solar energy should be incorporated to maintain consistent operation during low-sunlight periods.

European facilities benefit from modular designs that allow for scalable implementation, starting with smaller pilot projects before full-scale deployment. Local regulations and building codes must be considered, particularly regarding solar installation requirements and water quality standards. Many manufacturers now offer integration support services, including technical consultation and customised adaptation plans, making the transition more manageable for facility operators.

Solar-powered desalination represents a transformative solution for industrial water needs, offering a sustainable path forward in an era of increasing water scarcity. The integration of solar energy with desalination technology has demonstrated remarkable potential for reducing operational costs while minimising environmental impact across European industrial sectors.

The benefits of these systems extend beyond mere water production. Industries implementing solar-powered desalination units report significant reductions in energy costs, with some facilities achieving up to 70% savings compared to conventional desalination methods. Additionally, the technology’s scalability makes it suitable for various applications, from small manufacturing plants to large-scale industrial complexes.

Looking ahead, the future of solar-powered desalination appears promising. Technological advancements continue to improve system efficiency, while decreasing installation costs make the technology increasingly accessible. European initiatives supporting renewable energy integration are expected to accelerate adoption rates across the continent.

The growing emphasis on sustainable industrial practices, coupled with stricter environmental regulations, positions solar-powered desalination as a key solution for future water management strategies. As innovation drives further improvements in solar technology and desalination processes, we can expect to see wider implementation across various industrial sectors, particularly in water-stressed regions of Europe.

For industries seeking long-term sustainability and operational efficiency, solar-powered desalination represents not just an alternative, but an essential evolution in water treatment technology.

Leave a Reply